This is a review that tells how technology has advanced in pumping systems towards solutions that encourage energy savings and operational efficiency of the project.

by Alfredo Sotolongo*

This is a review that tells how technology has advanced in pumping systems towards solutions that encourage energy savings and operational efficiency of the project.

by Alfredo Sotolongo*

The most economical energy to produce is the one that is saved!

Among the most important advances in our industry is the evolution of both cold and condensation water pumping technology, which has achieved systems with optimal performance. I think it is important to mention the history of the development of such systems.

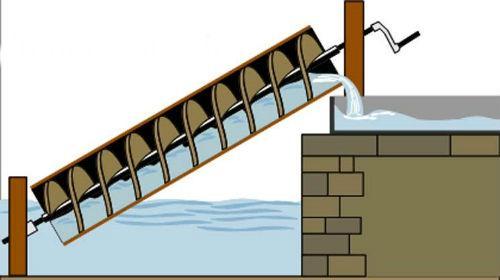

Of course, I'm not going to go back to the time of the well-known mathematician and inventor Archimedes. Who around the 200s, BC, developed archimedes' screw, which is a screw inside an inclined tube which, when rotated, transports water from a lower level to a higher level, as shown in Figure 1. This concept is still used today in irrigation systems and especially in the Netherlands, to drain flooded fields.

Figure 1. Archimedes screw.

From 1950 to 1990

Electric power in the 50s, due to its low cost, was not a determining factor. A typical air conditioning system using cold water was controlled with 3-way valves installed on the coils of the air units. These modulated the water allowing only the amount of water needed to compensate for the thermal load of each unit to pass through the coil.

The water pumps operated at constant speed handling 100% of the necessary flow at maximum load. This caused the water to return to the chiller at temperatures very close to the outlet temperature, which resulted in inefficient operation since the constant volume did not save energy when the system was at partial loads.

In many installations the pumps were selected for capacities greater than necessary, a practice that has continued over the years. This contributes to the waste of energy since to balance the system they increase the pressure drop to reduce the additional flow on which the original design was based.

From 1990 to 2000

In the 90s, with the increase in the cost of energy, it was necessary to be able to adjust the water flow and adapt it to the thermal load at each moment of the operation of the system. VFD drives were installed on the walls to modulate the pump motors and bring them to move the minimum necessary water flow. Locating the variable frequency drive near the pump motor was very important as the VFDs affected the thermal insulation of the winding of the motors.

This increased cost of energy forced consulting engineers to design air conditioning systems that minimized energy waste. The 2-way valves are introduced, which when the thermal load was lowered the thermostat proportionally closed the valve reducing the flow to the coil of the unit and increasing the pressure differential. Using variable frequency drives that received signals from pressure differential sensors, when the differential was increased by the effect of closing the valves, they reduced the revolutions per minute (RPM) of the engine, the water flow and therefore, the electrical consumption of the engine.

In reality, this arrangement did not meet the ASHRAE 90.1 standard, which requires 70% of engine power to be reduced when the thermal load is reduced by 50%. However, considerable savings were already beginning to be detected by proportionally adapting the water flow to the thermal load and not pumping the constant flow rate at 100%.

Early 2000s

To comply with the ASHRAE 90.1 standard, Armstrong Fluid Technology develops the "Design Envelope" concept. In it, the frequency inverter mounted on the pump motor and without needing pressure differential sensors manages to reduce 70% of the power of the motor when the thermal load drops to 50%. Through an algorithm programmed in the VFD, which includes the behavior of the pump, it compares the electricity consumption and revolutions of the motor at each moment with what corresponds to the true behavior of the pump, adjusting the motor to optimize its operation.

End of 2017

With the introduction of the new development, "Design Envelope Tango", using ECM motors and their algorithms for pumps with motors up to 10HP, Armstrong has achieved even better efficiencies than those required by ASHRAE 90.1 in the range of reductions of 80% and even more in many cases, for relatively small pumps.

What does the future hold?

With the technological advances that already exist and those that are being developed, we can see that the trend is to further minimize energy consumption, but at the same time, simplify water pumping systems and reduce their initial cost.

If you need more information on any of the topics covered in this column, please contact me at the mail: [email protected]

* President of Protec, Inc., is certified as a professional engineer in Puerto Rico and the state of Florida; has more than 40 years of experience in the application and sale of systems and equipment for energy conservation. He is a member of ASME (American Society of Mechanical Engineers), AEE (Association of Energy Engineers), ASHRAE and was president of the Miami chapter of that association.