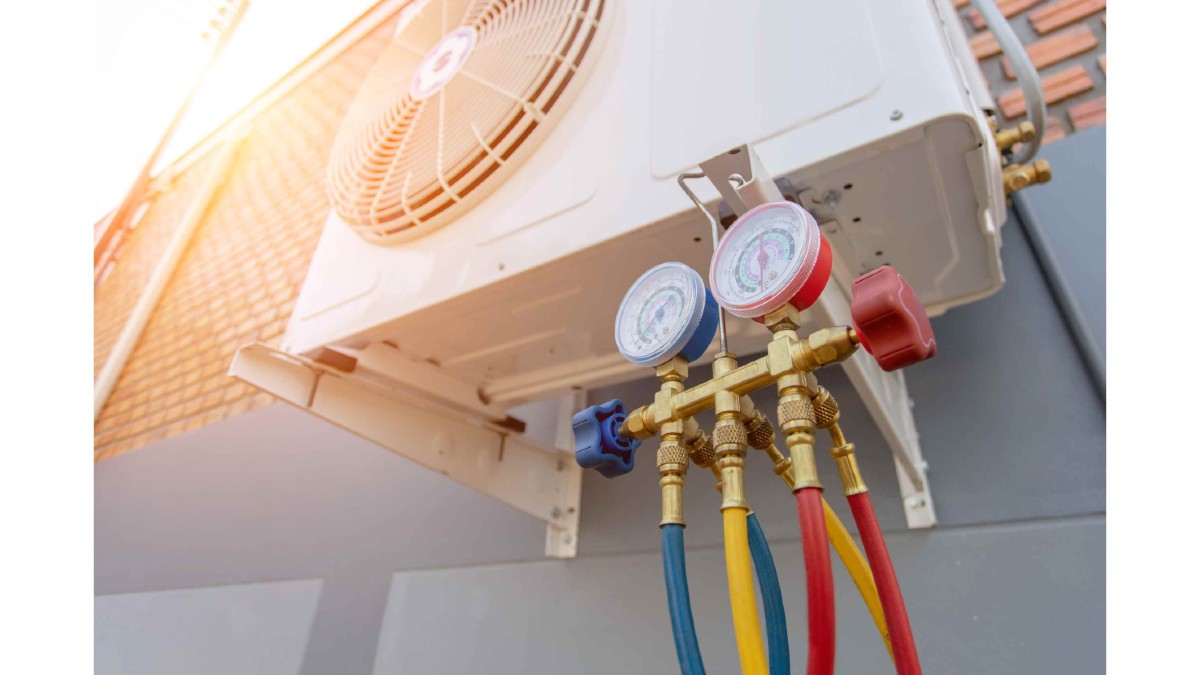

To improve knowledge and obtain successful results in your work in HVAC / R it is advisable to apply a triple vacuum technique that allows you to have a system as clean as possible.

Ing. Jimy Danelli*

For all of us who work in the refrigeration and air conditioning industry and have studied the inner workings of these systems, we know how important it is to keep our equipment free of pollutants and/or non-condensable gases.

Sometimes, in the trade of refrigeration and air conditioning there are high internal levels of contaminants, including humidity or amounts of air present in the system.

If you venture seriously into this profession, on some occasion when repairing a refrigerator or a refrigeration equipment with a history of having been contaminated with moisture, you will encounter this problem, and if it is not your case, I really tell you.

In this sense, to improve knowledge, ensure and obtain successful results in your work in refrigeration and air conditioning, it is advisable to apply a triple vacuum technique that allows you to have a system as clean as possible.

Triple vacuum

The technique consists of making vacuum three times, interspersing between each one, breaking the vacuum with a slight amount of nitrogen.

Triple vacuum utility

For technicians who serve customers who have their refrigerators and come up with the idea of removing with a knife the ice accumulated on the walls of the enclosure where they keep their frozen food, it happens that they accidentally break the pipes in the walls of the evaporator and the refrigerant gas begins to come out. To make matters worse, they don't disconnect the equipment, they keep making it work, which causes water to enter. This situation generates a high contamination of the equipment reaching in some cases to flood the compressor with water.

When moisture enters a refrigeration circuit, if it is not removed, the time will come when when it enters the capillary tube, due to the low temperature of the coolant, it will end up obstructing the passage of the refrigerant due to it freezing. That is why the dehydrating filter is placed before the capillary. However, with the entry of water it is not always enough to solve the problem with a new filter. What's more, the filter doesn't fix the problem. It is necessary to remove water or moisture from the circuit.

This task is not easy, but neither is it impossible. If you follow some advice and, with professionalism and dedication, the work does not have to be complicated.

Recommendations

The triple vacuum technique allows to minimize to a high degree the existence of humidity in the circuit. This can be definitively eliminated, along with the other techniques that include the treatment of any refrigeration circuit: sweeping of the circuit, removal of the compressor oil, washing of the compressor, replacement of the dehydrating filter and replacement of new oil.

Once the sweep of the low and high pressure circuit has been carried out and when the entire circuit has been assembled and a new dehydrator filter installed, the triple vacuum technique will be applied at the time of vacuuming.

To perform this technique, the following steps must be followed:

1. Vacuum normally. Make the vacuum on both the low and high pressure sides, to make it much more effective.

2. During vacuum, heat with a lamp or heat gun both the surface of the evaporator and that of the condenser and compressor. This will allow to eliminate even more the remaining moisture after the sweep.

3. After having made the vacuum for a reasonable time you stop the pump. Then, without losing the vacuum and having taken the precaution of purging the hose, slowly inject nitrogen or the gas that will be used by the equipment until you obtain a pressure of 2 PSIG. Leave for about 10 minutes.

4. After 10 minutes, the vacuum is "broken" when the pump is turned on. In this way, the pump sucks in those 2 PSIGs of nitrogen or gas pressure and will begin to remove the moisture that was absorbed by the gas. You make the vacuum for another 30 minutes.

5. After 10 minutes of vacuum, repeat the procedure from point 1 to point 4 for two more times.

When the system is vacuumed, what happens inside is that the internal pressure of the system begins to drop to the point that we modify the boiling point of the water and make it boil, or we make it evaporate at room temperature and our pump will be responsible for sucking the gases outside; on the other hand, if we do not have our vacuometer to know how much we are lowering the pressure of the system, we run the risk of lowering the pressure so much that we could modify the boiling point of the oil, causing it to begin to boil under certain conditions and we could suck it out of the system. That is why it is very important to emphasize that the correct vacuum is achieved by measuring not by the time we leave the pump working in the system.

Vacuum procedures

To be able to make our vacuum and eliminate moisture quickly, we can use certain simple procedures to execute.

The first of these will be to make a sweep with gaseous nitrogen to be able to expel as much moisture as possible by blowing it to the outside of the system. This process must be done with a cylinder of gaseous nitrogen and nitrogen regulator in between to avoid accidents, because it is only a small sweep with a pressure of 2 to 3 pounds.

The second of them tries that when starting the vacuum process it is done on both sides of the manifold, the pump will be connected to the center and the two valves must remain open: high and low pressure, until the desired vacuum is achieved.

The third point will be the one already mentioned above, which will be heating the system itself with lamps or with some other means to heat the tubes, evaporators, condensers, etc., so that the moisture evaporates.

Vacuum process for an ice water chiller or chiller

This process is useful if, for example, this system was a chiller, and we had the presence of water inside because our evaporator had crashed or the system was too long. Once we are ready to start the process itself we suggest this sequence of operations:

1 The vacuum pump is connected to the system.

2 The pump starts.

3 We stop when we have a reading of 1500 microns.

4 Break the vacuum with nitrogen and pressurize the system with 2 pounds.

4.1 We wait 30 minutes.

5 We evacuate nitrogen.

6 The pump is started.

7 We stop when we have a reading of 1500 microns.

8 Break the vacuum with nitrogen and pressurize the system with 2 pounds.

8.1 We wait 30 minutes.

9 We evacuate nitrogen.

10 The pump is started.

11 We stop when a reading of 500 or 250 microns is achieved depending on the type of lubricant.

12 We break the vacuum with the refrigerant gas.

13 And we gas our system.

The gaps that we will have to reach are the following:

500 microns if we work with mineral oil or alkylbenzene oil.

250 microns if we work with Polyester oil.

If during the process the oil from the vacuum pump turns white or takes on a milky appearance, what you will have to do is turn the ballast gas of the vacuum pump a quarter of a turn, so that that moisture that is in the oil is released, once the oil takes on its normal appearance, the ballast is closed again.

The vacuum pump should not be stopped, so as not to lose the progress of the work. In case this procedure is not enough it is recommended to stop the process, change the pump oil when it is hot, recharge the pump and continue.

It is advisable to change the pump oil after each vacuum while this fluid is still hot, since, if we do not, the subsequent voids will be slower and slower, in addition to the useful life of our pump will be reduced, due to which the internal valves begin to rust losing the seal.

* Jimy Danelli is an air conditioning and refrigeration maintenance consultant. You can write to the email: [email protected]