Although thermostatic expansion valves continue to occupy the first place of preference among players in the refrigeration and air conditioning controller industry, the market continued to evolve, leaving many behind.

Although thermostatic expansion valves continue to occupy the first place of preference among players in the refrigeration and air conditioning controller industry, the market continued to evolve, leaving many behind.

by María Cecilia Hernández Ocampo

When choosing an expansion valve that will be installed, either in a cooling system or in an air conditioning system, the market offers a varied range of elements. You have to know how to choose by analyzing the needs of the project. Focusing on the industrial refrigeration segment we can find a range of possibilities with different types of valves, each offering different advantages.

In an analogy used by Fernando Becerra Ariza, manager of the Refrigeration area of Danfoss S.A. the dynamics of this business in the Latin American region are summarized: "The growth of the expansion valve market is much higher than the growth of the Gross Domestic Product (GDP) of our economies". This is due, according to Becerra, to the great potential we have in improving our cold chain, which demands cold rooms, milk tanks, refrigerated transport, chillers, etc.

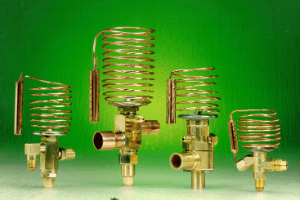

In addition to the improvement of the quality of life in the region, the increase in the air conditioning sector also demands all the elements of the cycle. In the opinion of Roberto Santana Cueva, application engineer at Emerson Climate Technologies, expansion valves could be classified into: automatic, manual, thermostatic, electrical and electronic. This categorization refers to the way the valve does the expansion. The most common and used in the market is thermostatic expansion, also known as VTE. And this is where other industry experts agree.

Engineer Gildardo Yañez, technical manager of Grupo Refrigerantes, explains that the thermostatic expansion valve is probably the most popular and most widely used flow control in the refrigeration and air conditioning industry. "The VTE is a dynamic valve that constantly modulates and regulates the passage of refrigerant to the evaporator to keep it properly fed, so that it can work in different operating conditions," says Yañez.

The valve depends on other elements

As Fernando Parra, sales manager for large users of Emerson Climate Technologies, explains, "a commercial refrigeration system can work with four basic components: the evaporator, the condenser, the compressor and the flow regulator, which in our case is the VTE". The function of the evaporator, Parra continues, is to absorb heat (cool); the condenser dissipates the heat that the refrigerant collected in the system; the function of the compressor is to raise the pressure and temperature of the gas (the pump); and finally the VTE, by analogy with the compressor, reduces the pressure and temperature of the liquid. Parra points out that with respect to the compressor and the VTE, in both cases, the compressor gives the refrigerant the conditions so that it can be condensed in the condenser and the VTE gives the refrigerant the conditions so that it can be evaporated in the evaporator and produce the refrigerant effect.

Contextualized this topic, Yañez and Parra agree that the characteristics that must be evaluated to select an expansion valve are:

- The capacity of the evaporator in Kcal. / hr., or Btu. / hr. o Kw. or Tons of refrigeration.

- Operating conditions: evaporation and condensation pressures and temperatures (application).

- The pressure drop through the valve, including that of the liquid distributor.

- The liquid temperature at the valve inlet. The lower the liquid temperature, the capacity of the valve increases and vice versa.

It is essential:

- Know if the VTE will be with internal or external equalizer (equalizer). The internal equalizer VTE is for evaporators without pressure drop.

- Verify that the type of refrigerant is the same as that used by the cooling system.

- Note that the expansion valve is selected in relation to the evaporator.

A giant step

Despite the great technological advances that this industry has had, thermostatic expansion valves are still the most used. However, these new developments are gaining ground with very good results. "Definitely the most important advance that is changing the way we look at systems and their regulation is electronics, and expansion valves do not escape this. Basically the electronic expansion valve (VEE), operates based on the positioning of an actuator that can be powered by a stepper motor or by a pulse system, "says Giovani Barletta, technical manager for the Andean Region, the Caribbean and Central America, of Emerson Cimate Technologies.

The trend is to develop new equipment and components focused on reducing energy consumption. Currently we can see high efficiency compressors, micro channel exchangers, plates, variable speed drives in condensers and compressors, electronic controls and controllers. "Among the electronic controls we have expansion valves with energy savings of more than 15%, which improve the administration, control and security of the system," says Fernando Becerra. But there the advantages of VEEs do not stop. According to Roberto Santana, these control in a very precise way the flow of refrigerant to the evaporator, as well as the overheating of the gas at the exit of the evaporator.

Likewise, its response time to open or close is very short; its closure is positive, which eliminates the use of a solenoid valve; they are multifunctional, that is, they can be used as pressure regulating valves, for hot gas diversion or to control the liquid level.

Thermostatics, the number one

What is certain is that new technologies, especially VEEs, do not yet occupy the place they deserve. The cause of this may be the resistance to change inherent in human beings, after all, evolving always requires going through a stage of chaos. For Rodnei Peres, export manager at Full Gauge Controls, "the way of thinking shifted focus. We have stopped working thinking only about one variable. Now, we're not only working to maintain the right temperature, but also how we're going to maintain that temperature."

Peres explains that the controllers are now integrated into other variables that are necessary to guarantee optimal operating conditions, work is done on issues of overheating and subcooling and the work is focused on the lowest energy consumption. "However, there is still a disadvantage: the initial cost is high compared to that of a thermostatic valve," says the Full Gauge representative.

Faced with the "cost" factor, VTEs remain the number one option. In part, according to Fernando Parra, because a valve of these well selected, well installed, which has not been moved by the overheating setting should not fail, it does not have to fail, since it responds only to pressure and temperature. In most cases the valve fails because the system conditions have been altered, because it is poorly selected or poorly installed, but not because it has been damaged. "That is why today in the American market what prevails for refrigeration and commercial air conditioning is the VTE, which is undoubtedly for more than 95% of the facilities," argues Parra.