Saving energy is one of the most sought-after concepts in recent times within our industry, and the principle of capacity control is one of them.

Saving energy is one of the most sought-after concepts in recent times within our industry, and the principle of capacity control is one of them.

by Alonso Amor*

The continuous search for more efficient solutions has led the refrigeration industry to the implementation of systems focused on having a high impact energy saving, offering sustainability to both stored products and equipment.

There are several strategies aimed at saving energy in the industry, being that many of them have as a principle the control of capacity.

Every cooling system is calculated on the same principle: there is a fixed thermal load (to a design condition) under which the equipment is sized and based on the selection it must be controlled. There are several factors that cause the load to be variable, such as: the ambient temperature, the temperature of the product throughout the day (or process) and even the thermal load resulting from the operation of the premises itself (opening and closing doors). All these factors bring as a necessity a control of the capacity of the system.

There are different types of capacity control, the most common are those that base their operation on turning the system on and off, however, this measure does not bring any benefit in energy savings to the installation. This text seeks to publicize the benefits of those solutions where, in addition to having a variable capacity, there are benefits in energy savings and sustainability of the system. The solutions that will be addressed are the following:

- Variable capacity compressors

- Electronic expansion valves

- Floating suction

- Evaporator/condenser fan speed control

The principle of energy saving in refrigeration installations can be seen from different angles, however, the objective is always common: to use the minimum capacity necessary in the most efficient way to guarantee the desired conditions in the stored product.

Variable Capacity Compressors

In order to control the capacity of a cooling system, without a doubt, one of the main points is the control of the compression stage. There are several ways to do this, the most common of which is to divide the total load into different compressors to have different stages of capacity according to the current load required. This is the technique most commonly used by supermarket refrigeration systems, where these sets of parallel compressors are better known as racks.

Compressor racks have been the most used solution in cooling systems with capacity control, however, due to their robust control (capacity control is a function of the number of compressors) they do not represent an optimized solution that in addition to seeking demand control contributes to the need for better temperature control and system adjustment.

An improvement to this type of system is the incorporation of capacity control by means of dischargers incorporated into the compressors individually. With this it is possible to have a greater number of control stages and thus obtain a more stable condition of suction pressure and temperature. Dischargers are usually applied to reciprocating compressors by means of blocked suction, that is, the gas is prevented from entering the compression chamber, leaving the pistons in motion without refrigerant flow. This technique is applied by heads, for example for a three-head compressor (six pistons) you will have 100%, 67%, 33% and 0% capacity respectively.

The methods mentioned above are effective and help to have a control of the installation, however, the current requirements of the facilities have led the refrigeration systems to use even more precise methods with more exact capacity variations and notable benefits in electricity consumption.

Faced with this need, two types of technologies have been applied: capacity control by frequency inverter (variator) and capacity control by digital technology.

Control by frequency inverter

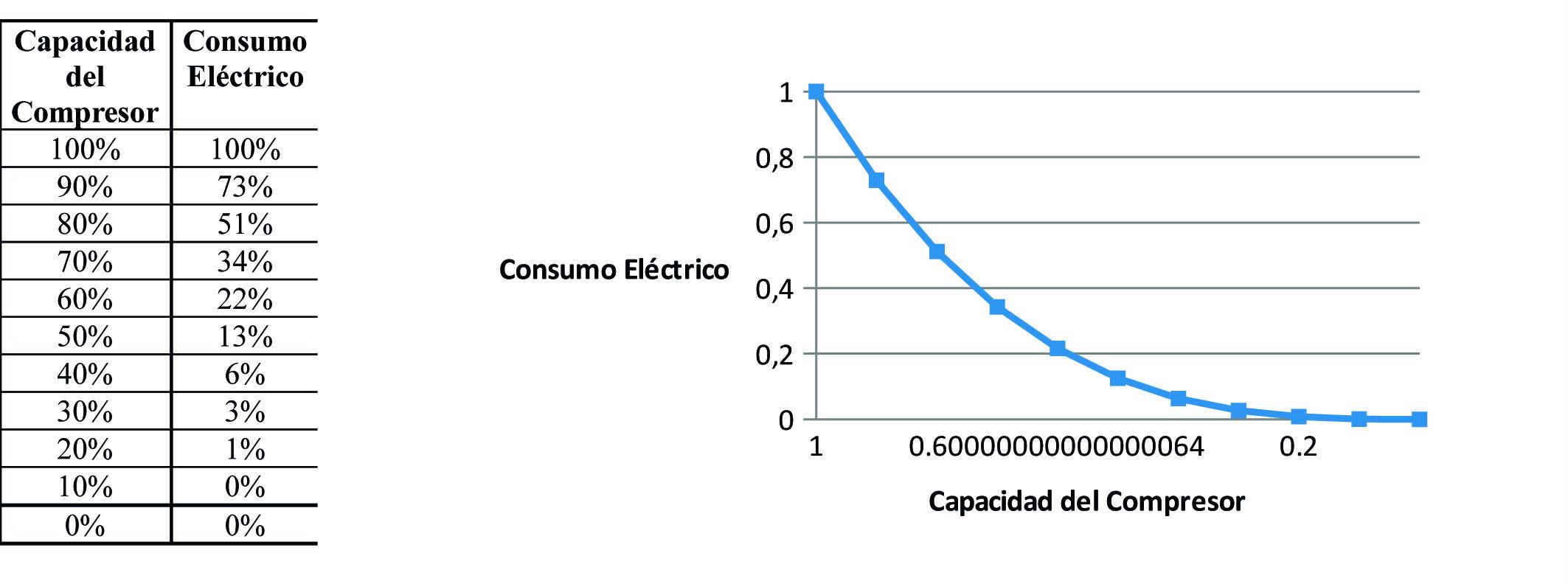

It consists of the variation of the electrical frequency of supply of the compressor, with this a modulation in the speed of rotation of the motor is achieved, thus controlling the capacity of the compressor. From an energy point of view, this method has great benefits due to the fact that while the capacity is modulated in a linear way, the energy consumption falls into a cubic relationship (see graph 1).

In this way as long as 100% of the compressor is not necessary, not only can you have an excellent modulation but also a positive effect in terms of energy savings. In addition, there is as such no electrical limitation for frequency modulation within the operating ranges of the network, so the capacity stages can be as fine as the accuracy of the inverter used.

Figure 1: Capacity/Consumption Curve Compressor with Frequency Inverter

For example, if the compressor is working at 80% of its rotation (40 Hz) its cooling capacity will also be 80% and its electricity consumption will only be 51%.

Capacity control by frequency inverter is a fairly effective method, however, the limits established by the compressor manufacturer must be considered, as there are restrictions mainly linked to working in low rotations since it can lead to lubrication deficiencies. The natural frequency of the compressor must also be taken into account, because when crossing by this value the system can enter into resonance generating strong vibrations and even rupture of pipe or components. Commonly compressors with frequency inverter work in a range between 25 and 60 Hz depending on the application.

Control by digital technology

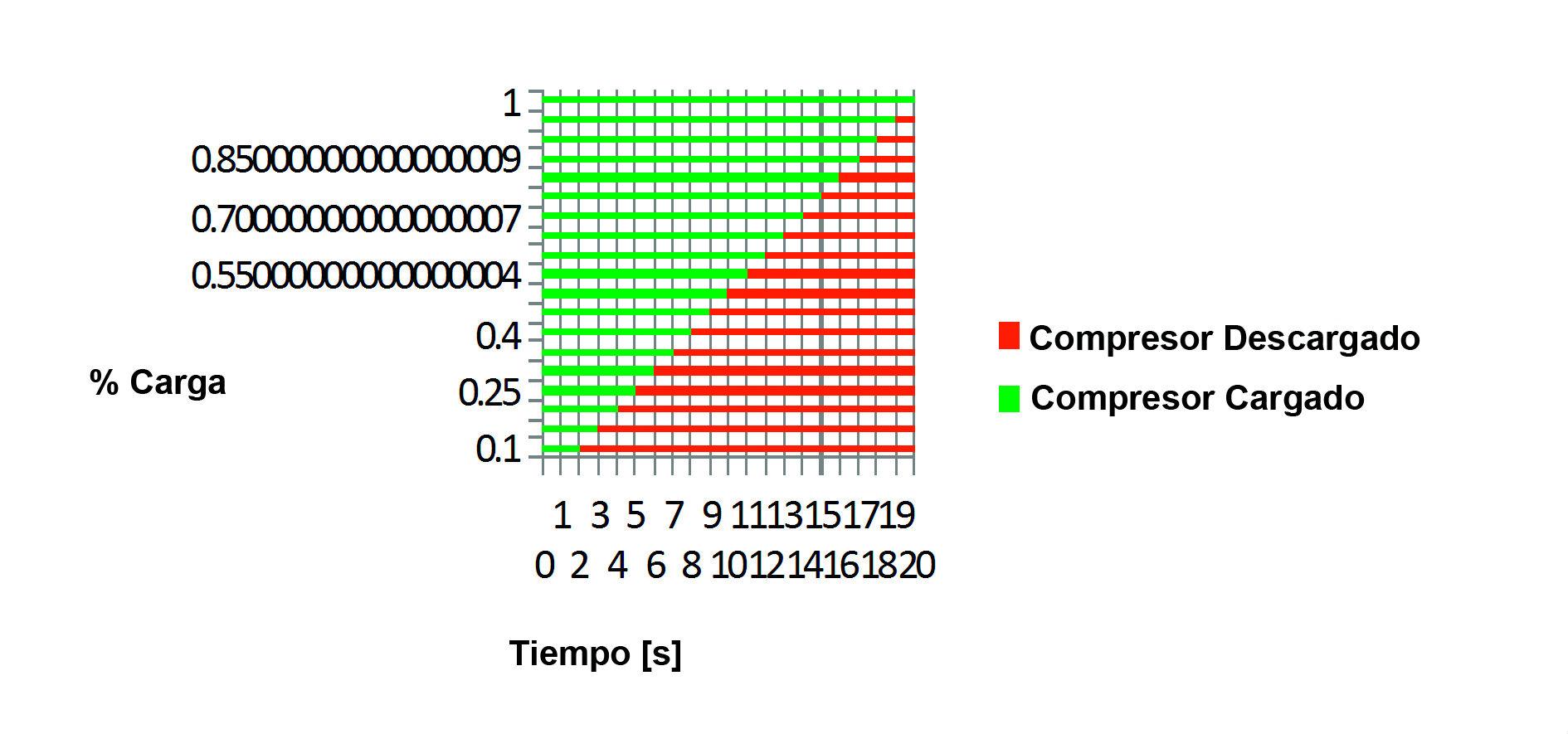

It consists of intermittent compression in a fixed interval, where the percentage of capacity will be given by the percentage of that interval in which the compressor (or part of it is compressing). For example, in an interval of 20 seconds a compressor will be at 50% if it compresses 10 seconds and the remaining 10 seconds works in a discharged manner (see graph 2).

Graph 2: Modulation of Digital Compressor in Interval of 20 Seconds

In this method of capacity control the engine always works at a constant rotation, the energy consumption varies according to the presence or absence of refrigerant gas inside the compression chamber, it is calculated that when the compressor is discharged it consumes 10% of energy compared to its work in compression regime.

In Scroll compressors, modulation occurs over 100% capacity of the compressor, this is achieved by separating the spirals. Already in reciprocating compressors this technology is applied only to one head (by blocked suction) leaving the possibility of having additional capacity control in the remaining pistons.

Note: in the following article we will continue with the development of these recommendations for the capacity control of cooling systems, delving into topics such as electronic expansion valves, floating suction and fan speed control.

* Eng. Alonso Amor. Technical Manager Flow Controls Latin America. Emerson Climate Technologies. Guadalajara, Jalisco, Mexico. [email protected]