We enter the third chapter of this special on compressors for refrigeration. After knowing the recommendations on screw compressors, we come to the topic of performance and application.

by Germán Robledo*

We enter the third chapter of this special on compressors for refrigeration. After knowing the recommendations on screw compressors, we come to the topic of performance and application.

by Germán Robledo*

With the passage of time, our society is increasingly concerned about the high cost of energy. When considering the purchase of equipment, more emphasis is often placed on running (energy) costs than anything else. For this reason, the BHP/tonne ratio is becoming increasingly important when selecting refrigeration equipment. From a compressor point of view, BHP/tonne can be translated into efficiency.

This article discusses compressor efficiency and the factors that affect it. The efficiency of compressors is normally described in terms of volumetric efficiency and isotropic efficiency.

Volumetric efficiency can be described as the ratio between actual compressor performance (ft3/min.) compared to scanning displacement (theoretical ft3/min.), according to the following ratio:

E.V. = real pcm x 100

pcm swept

Isotropic efficiency (also called adiabatic or global efficiency) can be described as the ratio between the actual and theoretical work of the compressor to produce a given capacity (pcm). The theoretical work can be determined from the pressure-enthalpy diagram for the refrigerant in question.

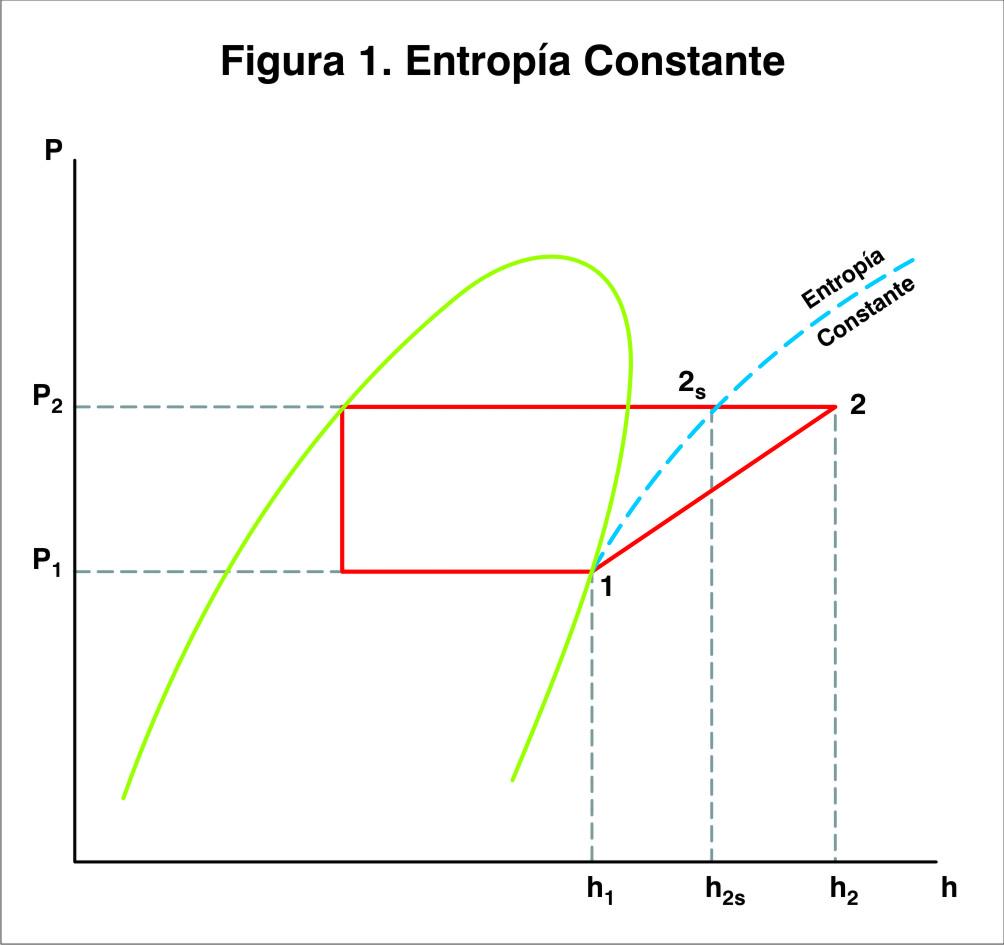

Figure 1 — Typical pressure – Enthalpy diagram

Figure 1. Condition one (P1) is compressor suction and condition two (P2) is compressor discharge. The actual work of the compressor is equal to h2 - h1. The isentropic work is equal to h2s - h1. The power and mass flow (M) of refrigerant through the compressor can be determined from performance tests. These numbers can then be used to calculate the following:

- Isentropic work:

Figure 1 — Typical pressure – Enthalpy diagram

Figure 1. Condition one (P1) is compressor suction and condition two (P2) is compressor discharge. The actual work of the compressor is equal to h2 - h1. The isentropic work is equal to h2s - h1. The power and mass flow (M) of refrigerant through the compressor can be determined from performance tests. These numbers can then be used to calculate the following:

- Isentropic work:

Wi = (h2s - h1) x M

42,42

where:

Wi = Isentropic BHP

h2s , h1 = BTU/lb

M = lb/min. of flow through the compressor

- Isotropic efficiency:

E.I. = Wi x 100

Wa

where:

Wa = Actual BHP

Isentropic efficiency has greater significance when talking about energy efficiency, because it directly depends on the amount of cooling capacity provided by each BHP input. Anything that causes the compressor power to increase (for constant pressure conditions) will reduce isentropic efficiency. In addition, if the power remains constant and the capacity (volumetric efficiency) is reduced, the isentropic efficiency is also reduced.

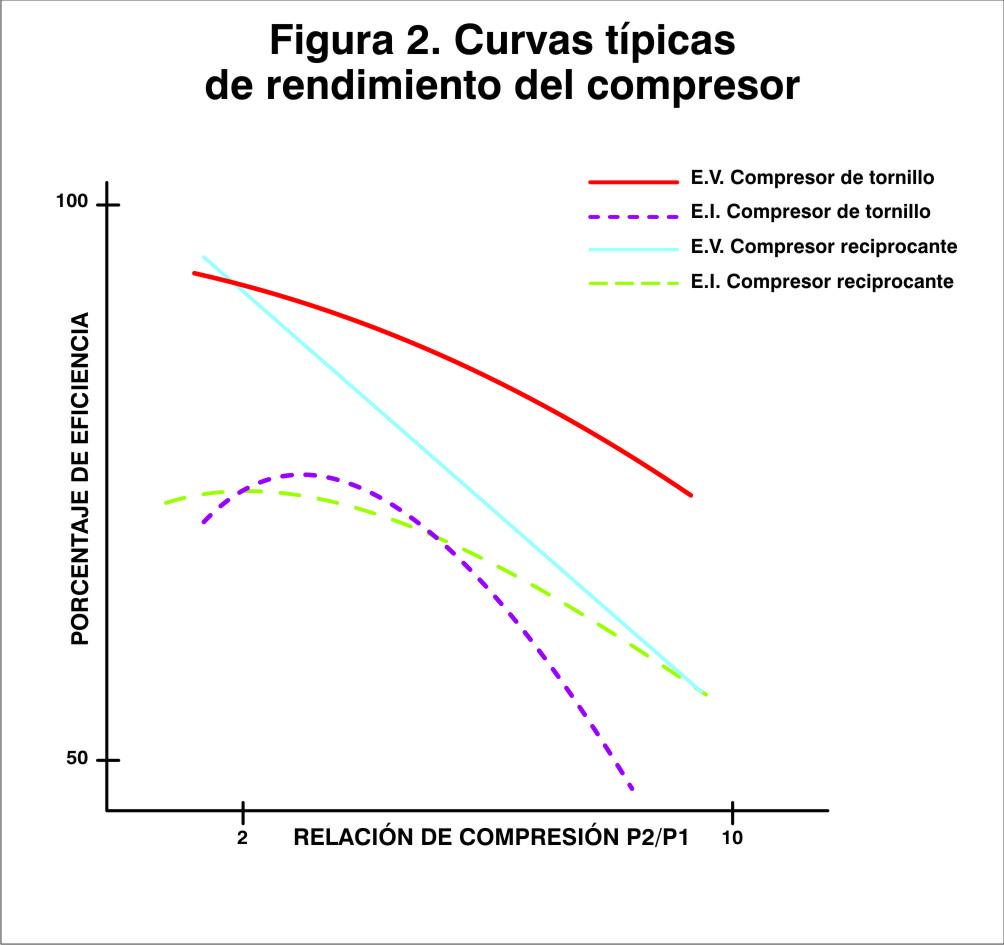

Volumetric efficiency, on the other hand, has little meaning when talking about energy efficiency. Its importance is related to the estimation of compressor capacity. To analyze the factors that affect compressor performance, typical efficiency curves for a screw compressor and a reciprocating compressor are shown in Figure 2.

Some observations and explanations in Figure 2 can be expressed as follows:

1. The volumetric efficiency of a screw compressor is reduced as the compression ratio increases (the absolute compression ratio is the ratio between the absolute discharge and suction pressures). This curve depends primarily on the internal adjustments of the compressor that allow leakage from the high-pressure side back to suction.

Total settings can be displayed as a single hole of equivalent size. As the compression ratio through the hole (adjustments) increases, the flow (leakage) also increases. A machine with very small settings will have a relatively flat E.V. curve and one with large settings will have a steeply sloping E.V. curve.

Some observations and explanations in Figure 2 can be expressed as follows:

1. The volumetric efficiency of a screw compressor is reduced as the compression ratio increases (the absolute compression ratio is the ratio between the absolute discharge and suction pressures). This curve depends primarily on the internal adjustments of the compressor that allow leakage from the high-pressure side back to suction.

Total settings can be displayed as a single hole of equivalent size. As the compression ratio through the hole (adjustments) increases, the flow (leakage) also increases. A machine with very small settings will have a relatively flat E.V. curve and one with large settings will have a steeply sloping E.V. curve.

2. The volumetric efficiency (E.V.) of a reciprocating compressor is also reduced as the compression ratio increases. However, the slope is generally steeper than that of a screw compressor. This depends primarily on the neutral volume (remaining adjustment in the upper dead center) of the reciprocating compressor. As the compression ratio increases, the neutral volume increasingly reduces volumetric efficiency (as the remaining refrigerant after each compression cycle occupies a larger percentage of the available volume).

3. The isentropic efficiency of a screw compressor is maximum with a particular compression ratio. The peak of the curve is related to the compressor's ideal integrated volume ratio. The curve drops sharply as the compression ratio moves away from the sweet spot, because the losses associated with the integrated volume ratio also increase. For this reason, a particular integrated volume ratio is limited to a compression ratio band around the peak of the isotropic efficiency curve. In addition, leakage from a high-pressure propeller back to a lower-pressure propeller will result in increased energy.

4. The isentropic efficiency of a reciprocating compressor is maximum close to that of a screw compressor, but it does not fall as fast on either side of its peak. The reason for this is that the reciprocating compressor does not have an integrated volume ratio but always agrees with the pressure conditions. Therefore, it does not have the losses associated with the built-in volume ratio. A reciprocating compressor is a true variable volume ratio machine.

There are several additional factors that affect volumetric efficiency. In a screw compressor, in addition to leaks, it is important to keep the injection oil away from compressor suction. There are two reasons for this. One is that the hot oil introduced in the preheat suction (overheats) the incoming steam and reduces its density, thus reducing the capacity of the machine. Secondly, the injection oil contains some drag refrigerant that ignites when introduced into the compressor. If this occurs in the suction of the compressor, the expanded refrigerant displaces part of the suction gas, which, in turn, reduces the capacity of the machine. For this reason, oil is injected after compression begins (the closed propeller) to avoid the aforementioned problems.

Many screw compressors carry the closed propeller injection a step further and inject the oil through the slide valve. In this way, the oil injection hole moves as the valve discharges the compressor, keeping the injected oil into the propeller closed during part-load operation. This improves the performance (efficiency) of the partial load.

In a reciprocating compressor, preheating of the suction gas should also be avoided. Although there is no oil injection to counteract, the cylinder will heat up more than the oil-flooded screw compressor. The temperature increases as the compression ratio increases. Some of this heat cannot help but add to the overheating of the suction, thus reducing the capacity.

If compressor capacity is considered constant, isotropic efficiency is affected by things that consume power. Friction and valve losses (pressure drops in the valves) for the reciprocating compressor and friction, viscous oil drag, discrepant integrated volume ratio and "propeller to propeller" leakage for the screw compressor are factors that affect the power. When comparing the performance of a rotary screw compressor with a reciprocating compressor, it should be remembered that overall or isentropic efficiency should be the point of comparison.

Overall efficiency is directly related to BHP/tonne. Although volumetric efficiency comparisons are important to the compressor designer, they should not be used for energy efficiency comparisons. The performance characteristics for each type of compressor must be taken into account when evaluating a particular application.

* German Robledo is a Mechanical Engineer. He has 15 years of experience in the industrial refrigeration industry, was manager of after market and services for the north of Latin America in the company York Refrigeration and is currently the sales director for Latin America of the company Vilter Manufacturing - Emerson Climate.

* German Robledo is a Mechanical Engineer. He has 15 years of experience in the industrial refrigeration industry, was manager of after market and services for the north of Latin America in the company York Refrigeration and is currently the sales director for Latin America of the company Vilter Manufacturing - Emerson Climate.