Use, protection, handling and operation are some of the tips you will find in this article about propane as a refrigerant.

by Jimy Danelli*

During a repair of a domestic refrigeration system I found that due to moving the client had broken the capillary tube. When reviewing what type of refrigerant gas the equipment had, I found that the refrigerant was R290, there I began to put into practice the basic safety principles for the use and handling of this type of refrigerant, which certainly does not present major complication if the safety recommendations established by international standards in its use and handling are followed.

Current trends in new green refrigerants are shifting towards the use of natural refrigerants, i.e. those that are present in nature and have virtually no or no pollution for the atmosphere and the environment; However, there are other conditions of utmost importance for the technicians who handle these refrigerants and safety measures that must be taken into account for their handling, storage and transport.

Security conditions and measures

First, the storage process should be in a cool, ventilated warehouse, away from fire or heat. The temperature should not exceed 30 °C. It should be stored separately with the oxidant, halogen, and avoid mixed storage. Illuminated, explosion-proof ventilation. Prohibit the use of tools and mechanical equipment prone to generating sparks. The storage area should be equipped with emergency treatment ventilation equipment.

The transport process on the axle

1. Only on the day of the amount of refrigerant R290 is allowed to charge a licensed pressure vessel, which allows to transport the vehicle. In our countries this license must be issued by the entity responsible for the use and management of substances that deplete the ozone layer or contribute to global warming, in addition, to obtain this license a training course on good refrigeration and air conditioning practices must be previously approved.

2. In the process of transportation, the installed R290 refrigerant containers must be tightened on the vehicle.

3. In the transport of R290 refrigerant vehicles must be equipped with a gas alarm device.

4. Smoking is not prohibited in the transport of R290 refrigerated vehicles.

The production process

1. All staff are prohibited from smoking.

2. Operational personnel may not wear clothing that produces static electricity.

3. To avoid working in a limited space you should be in a large space in production.

4. Prohibit all use of open flame work. All pipe connections must be connected by a locking ring.

5. The use of vacuum cleaners, hair dryer and other electrical appliances is not allowed.

6. When R290 refrigerant is discharged from the refrigeration system, the hose should be used to enter the outside atmosphere.

7. All substations shall be suitable for flammable and explosive gases.

Resolve R290 refrigerant safety issues

1. To prevent the accumulation of combustible gas, a strong ventilation device needs to be installed.

2. In addition to ventilation and safety systems, the need to configure standard electrical equipment explosion-proof.

3. With gas sensor components to continuously monitor the possible leakage area: when the concentration exceeds the minimum explosion limit of 15%-20%, that is, alarm and double ventilation; When the minimum explosion limit is 30%-35%, cut. Monitor the area of all non-explosion-proof electrical connections, leaving only the full-speed rotation of the explosion-proof fan.

4. Load R290 refrigerant into the equipment before the equipment needs to be shown for collection.

The R-290 and its handling

Propane gas is used in different applications in the refrigeration industry. One of its advantages is that it can be combined with multiple chemical elements.

It is very important that when handling it you take into account the different security measures, because this way you can protect your integrity and that of the people around you

R-290 or propane gas is a hydrocarbon used in some refrigeration systems, such as heat pumps, commercial refrigeration equipment, among other uses. When working with hydrocarbon-type refrigerants, make sure that they are of high purity, since any proportion of residues, such as sulfides or water, contribute to the degradation of the lubricating oils of the installation and the breakage of compressors, among other failures.

Also, if R-290 is mixed with other hydrocarbons, the physical and thermodynamic properties of the parent substance could vary dramatically.

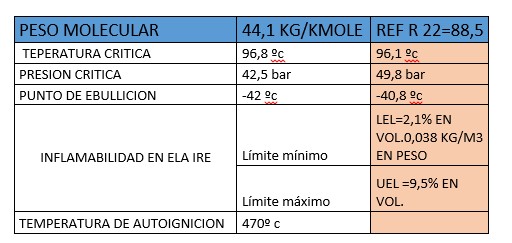

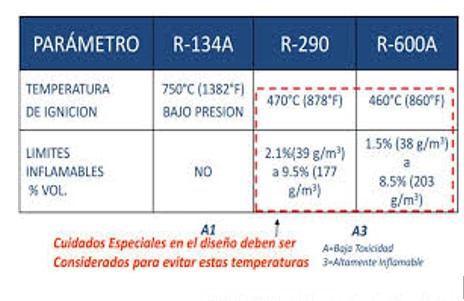

Table 1.

Therefore, it is necessary to implement good practices during its handling, because the propane used in refrigeration applications is not odorized like those for domestic use, which makes it difficult to easily detect in case of leaks.

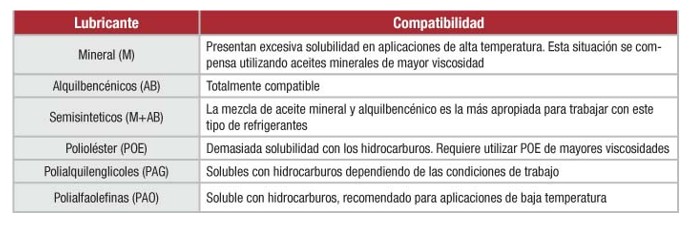

Compatible oils

Propane, like the rest of the hydrocarbon refrigerants, has very good miscibility with any lubricant. Due to this characteristic (common between these substances and mineral oils), there are systems in which it is necessary to use oils of higher viscosity to compensate for this excess solubility.

Compounds containing silicone or silicates are not recommended. In any case, the ideal is to follow the instructions and use the lubricants recommended by the compressor manufacturer.

Table 2.

Safety standards

As with other refrigerant gases, handling R-290 requires adherence to a set of rules to keep people safe and avoid any type of accidents, so be sure to check the following points in case of a leak:

* Close the gas passage in case you are not in danger

* Check for flames or sparks

* Do not turn on the lights or use electronic devices such as cell phones, conventional phones, among others.

* Leave the area immediately and make sure no one stays in place

* Gives escape notice for others to get to safety

* Do not return to the area until the propane supplier deems it safe

* Check the system to make sure there are no leaks

Technical recommendations

R-290 is a low-toxicity and highly flammable gas. Therefore, when you work with it, it is imperative that you do it safely and responsibly. In addition, it is characterized by being a simple asphyxiant that displaces oxygen in a polluted environment, in such a way that if you inhale it in large quantities you could experience sleep, dizziness, euphoria, anxiety, spasms and even narcosis.

Some properties that you should take into account when handling this gas:

*Flash point: -104°C

*Auto-ignition temperature: 450°C

*Explosive limits: Lower 2.1 percent / Top 9.5 percent. It forms explosive mixtures with air between these concentrations

*Occupational exposure limit:

simple asphyxiant

*Odor threshold: good warning property when containing odorant mercaptan

Symptoms of oxygen deficiency include the following:

*Concentrations of 12 to 16 percent oxygen in the air: rapid pulse and breathing, muscle incoordination

*Concentrations of 10 to 14 percent: euphoria, abnormal fatigue

*Concentrations of 6 to 10 percent: nausea, vomiting, loss of consciousness

* Oxygen concentrations below 6 percent: conclusions, collapse and death

Most of these effects are temporary and cease with the administration of oxygen or simply breathing plenty of fresh air.

Personal protective equipment

The Occupational Safety and Health Administration (OSHA) sets a TLV-TWA (permissible exposure limit in an average eight-hour workday) of 1000 ppm (1800 mg/m3) for propane gas. Based on this and the properties of the product, personal protective equipment is as follows:

*Respiratory protection: for concentrations lower than TLV it is advisable to use a half-sided respirator with filter for organic vapors (due to the content of mercaptan used as an odorant). For higher concentrations, however, use a respirator with air line or self-contained equipment, since there is no filter capable of capturing propane.

* Protective clothing: use materials that do not produce electrostatic charges, for example, in antistatic polypropylene, cotton or any other natural fiber.

* Visual protection: although propane does not produce effects on the eyes, it is advisable to use monoglasses or safety glasses, due to possible irritations due to mercaptan.

*Gloves: not necessary when not handling liquid propane.

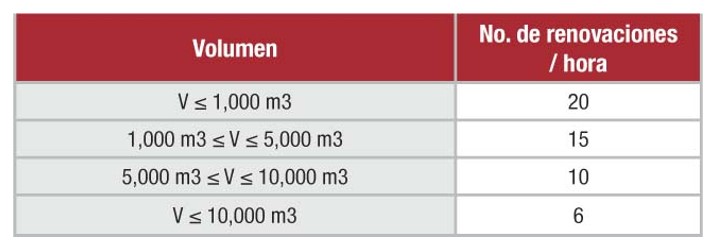

Propane gas ventilation in equipment repair shops

Depending on the degree of contamination of the premises, a greater or lesser number of renewals / hour of the entire volume of the same must be applied, as shown in table 3.

Table 3.

Gas extraction

There may also be a series of general indications that set the pattern to be followed in most cases:

(a) The air inlets must be diametrically opposed to the position of the fans, so that all the air used crosses the contaminated area;

b) It is advisable to place the extractors close to the possible source of contamination, so that the harmful air is eliminated without passing through the room

(c) Ensure that the exhaust fan is not close to an open window or other possible air inlet in order to prevent the exhausted air from being reintroduced or stagnant air pockets forming in the room to be ventilated

Localized ventilation

Localized catchment ventilation should be a priority over any other alternative, especially when toxic products are emitted in significant quantities. The following are the elements required for localized uptake:

Catchment system

Pollutant transport pipeline (in certain installations)

Separator system (if necessary)

The collection device, which in many cases is often called a hood, is intended to prevent the contaminant from spreading throughout the rest of the premises. This is the most important part of the installation, since a bad design of this device prevents the system from correctly capturing contaminants or can lead, to compensate for this poor initial choice, to the use of excessive flows, operating and installation costs.

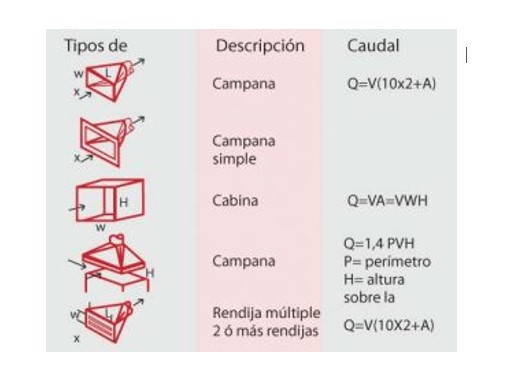

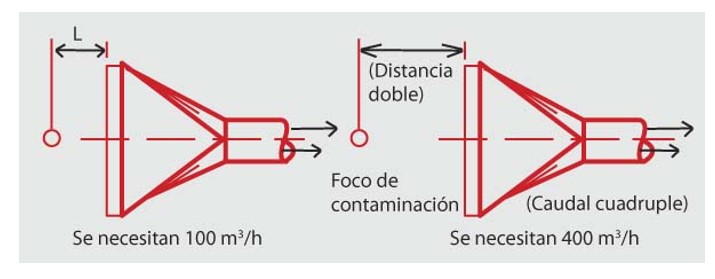

Figure 1.

This component takes various forms, as shown in Figure 1. For the collection device to be effective, minimum collection speeds must be ensured. This velocity is defined as "the velocity that the air must have to drag the vapors, gases, fumes and dust at the most distant point of the bell".

Transport pipeline

Once the collection has been carried out and to ensure the transport of the polluted air, it is necessary that the speed is inside the channeling and prevents the sedimentation of the solid particles that are in suspension. Thus, the dimensioning of the duct will be carried out according to the type of materials in suspension.

Table 4.

Design principles

The performance of a localized extraction depends, to a large extent, on the design of the collection element or hood. One of the most important rules is to place the collection devices as close as possible to the pollutant emission zone.

The effectiveness of suction devices decreases very rapidly with distance. For example, to capture a certain pollutant at a distance L, a flow rate of 100 m3/h is needed. But if the collection distance is twice (2L), then a flow four times higher than the initial one is required to achieve the same suction effect of said pollutant (figure 2).

Duct extraction and sizing system

To move the air through a localized extraction or a general ventilation system it is necessary to provide energy, in order to overcome the load losses of the system.

Table 5.

Table 5.

Most of the time, the energy input comes from fans although, in some cases, ventilation can be done by natural convection without the use of these devices.

* Jimy Danelli is a maintenance consultant in air conditioning and refrigeration. You can write to the email: [email protected]

* Jimy Danelli is a maintenance consultant in air conditioning and refrigeration. You can write to the email: [email protected]