Managing refrigerants throughout their life cycle so that they have the minimum harmful environmental impact was always a necessity.

by Eng. Ernesto Sanguinetti R.*

The Montreal Protocol of 1987 (with its subsequent amendments of London, Copenhagen, Montreal, Beijing) was established with the purpose of phasing out substances, including refrigerants, that contain CHLORINE because it was discovered that when escaping into the atmosphere they damaged the Ozone Layer that surrounds our planet, thus establishing the Ozone Depletion Potential (ODP) that identified the little or much that each of them affected the ozone layer.

The schedule established for its elimination gave enough time for substitute refrigerants with very low or no ODP to be found and thus the much-used R-12 refrigerant was eliminated, among others, and for our Latin American countries we are in the last stages of eliminating the use of R-22 refrigerant.

Then came the Kyoto Protocol in 1997 (with its Kigali amendment) to phase out, following another schedule, the use of refrigerants that have a high "greenhouse effect" or high Global or Atmospheric Warming Potential (GWP) because it was discovered that the leak into the atmosphere of those refrigerants that replaced R-12, R-22 and R-502 such as R-134a, R-410A, R404A, R-507A, and others; while they have ODP=0, they nevertheless contribute to global warming or global warming; that is, they have high GWP.

For its part, the European Union, regardless of these agreements/protocols mentioned, established its own calendar to eliminate faster the use of refrigerants that produce "greenhouse effect" and those agreements that are currently being complied with are called the F-Gas Regulation or Regulation (EU-517/2014).

As a result of what has been explained, now the refrigerants that are being used as new substitutes must have and have medium, low and zero atmospheric warming potentials (GWP), being the ideal that they have GWP = 1 or better GWP = 0.

In addition to new synthetic refrigerants (pure and blends), natural refrigerants such as hydrocarbons, carbon dioxide (CO2 or R-744) and ammonia (NH3 or R-717) are being used, which was never stopped using but is expanding its applications; all with very low GWP. For reference: CO2 has GWP = 1, and ammonia has GWP = 0.

We must not forget what was already mentioned in many previous articles that we must also eliminate or reduce the "indirect greenhouse effect" that is no longer due to the direct leakage of refrigerants into the atmosphere, but is due to the fact that the electrical energy needed and consumed by refrigeration or air conditioning equipment comes from a plant that generates electricity using fossil fuels that when "burned" have as a product from combustion to CO2 that goes with the "fumes" into the atmosphere through chimneys, WITH CO2 being largely responsible for global warming.

Additionally, it is recommended to use high energy efficiency equipment to minimize electricity consumption for each TON, Kcal/hr or BTU/hr of cooling capacity produced and even better if the electricity generated comes from a plant or plants that use renewable energy sources such as hydro, solar, wind.

For all the above, the management of refrigerants throughout their life cycle so that they have the minimum harmful environmental impact was always a necessity. IMPORTANT: Refrigerants are made so that all their lives they remain confined in their containers or within the refrigeration circuit of the equipment.

We know that in its beginnings it was not given due importance, perhaps due to ignorance, because there was a bad habit (we can not deny that until now some do) of "eliminating and purging existing refrigerant inside the equipment and even its containers throwing them directly into the atmosphere". However, knowing the problems we cause to our environment and pressured by the changes of the usual refrigerants by substitute refrigerants becomes a necessity today, so much so that this management goes from the process of production of refrigerants, packaging, their sale, their loading and use in refrigeration and air conditioning equipment; the services we do in the equipment and also when it is finally defined that the existing refrigerant is going to be changed for another refrigerant.

Everything leads us to the recovery of refrigerants in containers so as not to throw them into the environment while we do maintenance or repair or decide if we re-use them or we are going to keep them stored inside their containers because we prefer to use a substitute refrigerant in their replacement. This is where the concepts of refrigerant recovery, recycling and regeneration come in.

Refrigerant recovery

Refrigerant recovery means removing the refrigerant fluid from a new or used refrigeration or air conditioning system and storing it in an external metal container or container, without analyzing or processing it. This refrigerant recovery mechanism is the most important action that must be carried out to comply with the regulations on the replacement of CFCs, HCFCs, HFCs with new refrigerants and ensure that our atmosphere is not contaminated or damaged.

There is also the possibility of re-using them, but you have to be careful because the coolant can be contaminated with air, be mixed with another coolant or with nitrogen, have acids, water or particles generated when an engine burns. A recovered refrigerant should not be used in the same system or another unless you are sure it is clean.

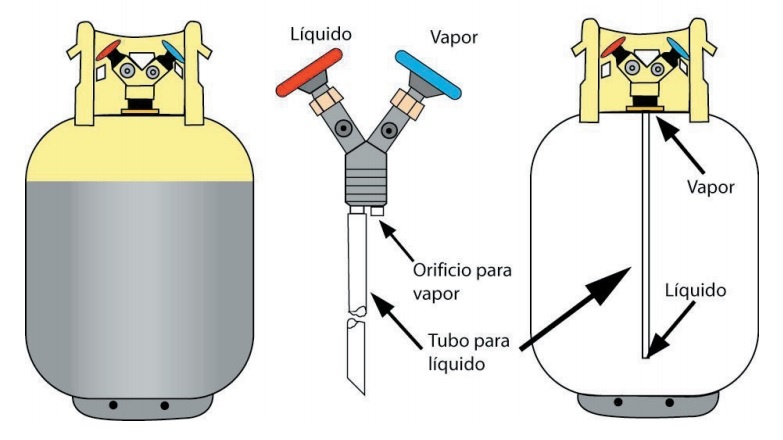

There are recovery equipment of various brands and designs, which serve to extract the refrigerant in the condition it has within a refrigeration or air conditioning system and store it in a "recovery cylinder". Recuperators can extract refrigerant in the form of liquid or vapor; and many of them can remove a high percentage of the oil that comes mixed with the refrigerant. After storage in the recovery cylinder, the future of the refrigerant will be decided.

We show some equipment and instruments that are used:

Recovery Teams or Recuperators

Containers to recover refrigerants

Refrigerant Identifier

Scale or Digital Scale

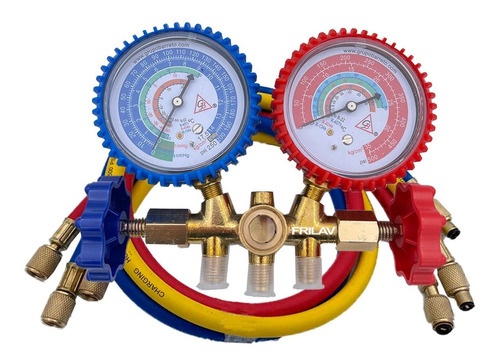

Manifold sets with analog hoses and pressure gauges or digital pressure gauges.

Remember the importance of not releasing refrigerant fluids directly into the atmosphere during repair and/or maintenance work on any equipment. After its recovery it must be decided whether it is re-used or needs a treatment or is stored in its container.

Refrigerant recycling

Recycling is understood as the process of cleaning the refrigerant when you want to reuse it. As there may be contaminants mixed with the refrigerant, it must be passed once or several times through dehydrating filters of type cartridges or special desiccant blocks, which are characterized by reducing moisture, acidity and impurities that may exist.

Normally the recycling is done in Recycling Centers specialized in it. Recycling while significantly reducing contaminants through the separation of oil and other contaminants; it does not give us the assurance or guarantee that it will return the refrigerant to the manufacturer's original purity specifications.

Refrigerant regeneration

Regeneration involves a series of processes that are carried out with the refrigerant so that it reaches the characteristics equivalent to that of a virgin refrigerant. As regeneration includes the procedures of filtering, drying, distillation and chemical treatment, the recovered refrigerants must be stored in standardized bottles and taken to Regeneration Centers, where they will be responsible for doing previous chemical analysis to know if they can regenerate or not.

The difference between the processes of recycling and regeneration of refrigerants is in the quality control to which they are subjected. Recycling involves a basic cleaning of oil and other impurities, but is not tied to any procedure that has a valid treatment certificate; however regeneration involves professional cleaning of oil, moisture levels and other impurities; giving the assurance that the regenerated refrigerants are identical to the originals, so the Regeneration Centers deliver the regenerated refrigerants in their containers duly labeled and with their respective certificates.

As a final comment, we can add that in Peru, the Ministry of Production with the support of the UN through the UNDP (United Nations Development Program) has managed to establish and become operational since this year FIVE Recovery and Recycling Centers: Three in the city of Lima, one in the city of Piura and one in the city of Arequipa.

* Eng. Ernesto Sanguinetti R. - Manager of the Engineering Division of COLD IMPORT S.A. - Lima - Peru.

* Eng. Ernesto Sanguinetti R. - Manager of the Engineering Division of COLD IMPORT S.A. - Lima - Peru.