We present four recommendations that allow the recovery of non-flammable synthetic refrigerants in a refrigeration system to be carried out in an adequate way.

by Eng. Gildardo Yáñez*

Recovering refrigerant means transferring the gas from the cooling system to a cylinder without applying any process to the refrigerant. Below are four ways to carry out the process correctly.

1. In the gas phase

This procedure is usually the slowest since the gas flow is lower in the gas phase. It should be borne in mind that the connection hoses between the recovery machine, the cooling system and the recovery tank must be of the minimum possible length, as well as the maximum possible inner diameter, in order to contribute to increasing the performance of the process.

The coolant, in the steam phase, is normally sucked in by the suction machine and, once condensed, is sent to the recovery tank.

There are two ways to connect the machine to recover steam, as the case may be:

In the set of pressure gauges on both sides of the compressor (medium commercial systems)

Only on the low side, where a puncture valve must be installed to extract the refrigerant, and the amount to be recovered is small (domestic refrigerators, low capacity air conditioners)

2. In liquid phase

Because reciprocating compressors can only work with refrigerant gas in the gas phase, it is necessary to evaporate everything and extract it from the system before it reaches the compressor. To evaporate the refrigerant that is in liquid phase in the system, it is necessary to add heat (through safe practices).

In case the recovery machine does not have an evaporation system, it must be protected against the arrival of liquid refrigerant using the set of pressure gauges to dose, through the operating valves, its entry from the system to the machine (using them as if they were an expansion device) during the initial stages of recovery.

The liquid coolant can be recovered by decantation, separation or push/pull techniques, with the consequent oil dragging.

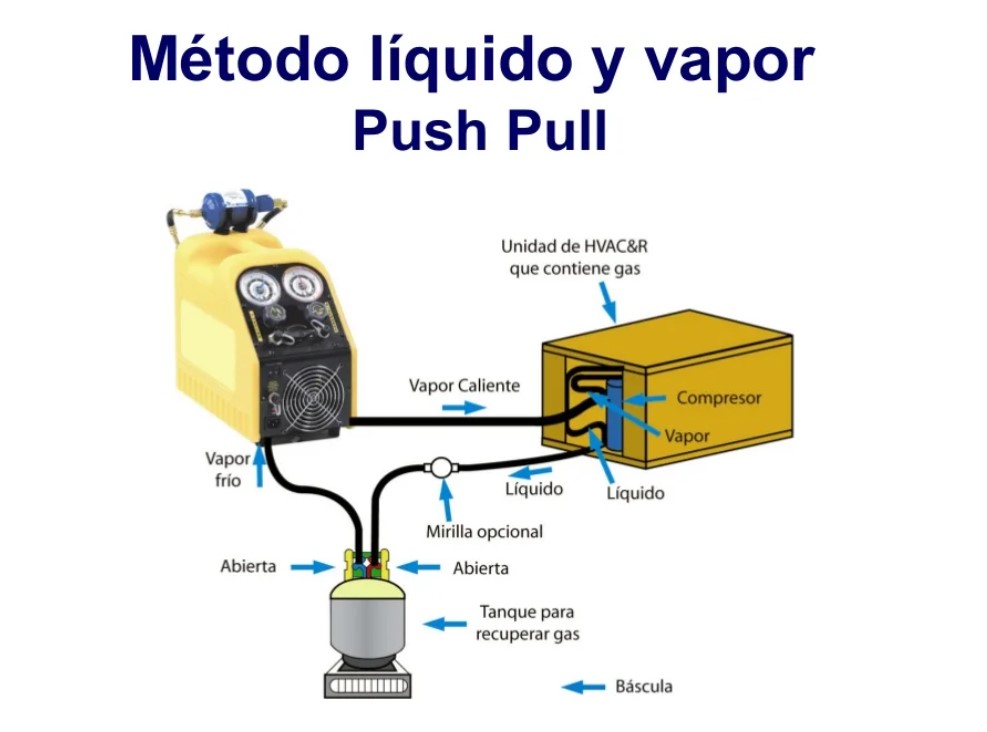

3. Push/Pull (suction and feedback)

It is carried out using steam from the cylinder to push the liquid coolant out of the system. A hose is connected from the liquid port of the unit, the coolant of which is required to be removed, to the liquid valve in the recovery tank. Another hose is connected from the steam valve of the recovery tank to the suction inlet of the recuperator and finally a third hose is connected from the outlet or discharge of the recovery machine to the steam port of the equipment.

The recovery tank will suck the liquid coolant (pull movement) from the deactivated air conditioning unit, when the recovery machine lowers the cylinder pressure. The steam sucked from the recovery tank by the recovery machine will be pushed back (push movement), compressed to the side that corresponds to the steam in the deactivated HVAC&R unit.

Once most of the coolant has been loaded from the system to the recovery tank, the recuperator will begin cycling, controlled by its low pressure pressure switch, removing the rest of the coolant in the form of steam. When the recovery machine no longer cycles and comes to a complete stop, that indicates that as much coolant as possible has been recovered from the system.

The push/pull method is not used if:

• The system has a load of less than 9 kilos or 20 pounds of refrigerant.

• The equipment is a heat pump or other system where the liquid coolant could be isolated

• The equipment has an accumulator between the service ports, used to recover liquid

• A migration of liquid coolant has occurred, and its location is unknown

• The design of the pipe in the equipment does not allow to create a solid column of liquid

• If the push/pull method is used:

• A peephole is needed, to know that all the liquid has been recovered

• Have a third hose ready

• After all the liquid has been removed, the hoses must be reconfigured to recover steam, as this method does not make a vacuum in the system

4. Liquid and steam

It is important to know the type and amount of refrigerant to be recovered. Whenever possible, the pivot valves or Schrader valves must be removed from the service ports, hoses with integrated ball valves must be removed beforehand and try to remove the liquid from the system first and then the remaining steam, this action accelerates the speed of gas recovery.

With large amounts of coolant, it is better to use the push/pull method, as it is three times faster than doing it directly. When possible, it is advisable to recover gas from the high and low pressure sides of the system and use short hoses for service (long hoses increase process time).

If when you start removing liquid from the system, the compressor sounds, you have to know that this damages it because it reduces its useful life significantly.

Recovery of the steam side in the recovery tank should always be done, this reduces the possibility of the presence of remaining liquid coolant in the lines. This ensures a cleaner process. During gas recovery, at the time of removing the hoses, a line of liquid refrigerant may come out when finished.

Note: Using a dehydrator filter in all processes is a protection for the recovery machine. This recommendation becomes relevant when recovering refrigerant from a system in which a compressor was burned.

* Gildardo Yáñez. Specialist in Refrigeration. Member ASHRAE. https://www.gildardoyanez.com/ - [email protected]