The increasing number of refrigerants and substitutes now available has significantly increased the chances of a system being loaded with various refrigerants.

by Eng. Jimy Danelli*

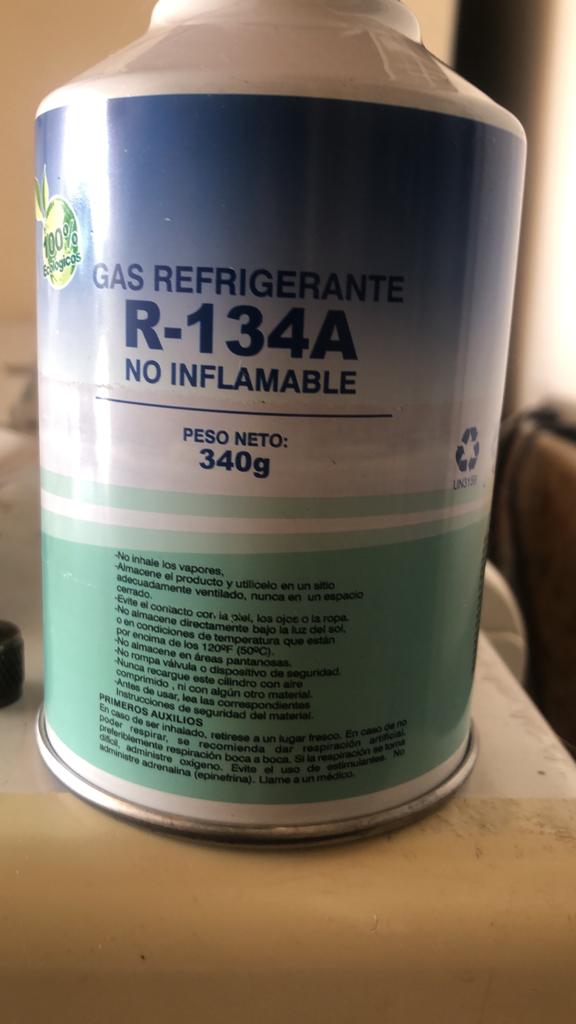

Performing a repair on an air conditioning system that uses R 134ª refrigerant with screw compressor, I could notice some irregular conditions after a good triple vacuum and sweep with nitrogen. When starting the system I detected that the pressures were somewhat irregular, that the overheating and sub-cooling was not within the parameters, I thought it was the expansion valve, which was the filter dryer, which were the coils, which was even the compressor; well I thought it couldn't be the coolant as the new sealed cylinders and in its box didn't have any alterations.

Well, I started the repair again, but now with another brand of refrigerant. The behavior of this new brand generated an ideal operation without disturbances or abnormal conditions, this I think was because at present a growing number of companies that distribute and / or transfer gases have proliferated worldwide, I even believe that in each country there is no institution that certifies and guarantees that purity the refrigerants have.

In the field of refrigeration and air conditioning and by virtue of the accelerated changes that have been generated in terms of new refrigerants, regulations on the use and handling of refrigerants, on the recovery and regeneration of these refrigerants. Who could give us the confidence that what we are using is a 100% pure refrigerant or that its components being a mixture are in adequate quantity and quality.

Counterfeit refrigerants have been in the news a lot lately, as manufacturers claim that record amounts of illegal HFC imports are being brought into the United States and around the world, under customs' radar. While some of these imported refrigerants may have the correct composition, there is evidence that others may be counterfeit or of low quality.

Mixed refrigerants

Mixed refrigerants are another problem that professionals frequently encounter in the field, and they are also a major concern. Mixed, low-quality refrigerants can not only damage HVAC-R systems, but can also pose a threat to the safety of technicians who are servicing the equipment, especially if it is a flammable or toxic component.

In the field, the only way to determine whether the refrigerant meets the AHRI 700 standard, which specifies the purity requirements of refrigerants, is to test it with an analyzer (recovery companies have more comprehensive analysis capabilities). While these can be expensive tools, some say they're worth the investment.

The increasing number of refrigerants and substitutes now available has significantly increased the chances of a system being loaded with various refrigerants. Not only can this have an adverse effect on an HVAC-R system, but it can make it difficult for professionals in the area to receive the best price for their recovered refrigerant.

In fact, refrigerant analyzers can be expensive, with premium units costing about $4,000 or more, which is why they're not routinely found at most companies in the industry.

An analyzer is mainly used by recuperators or anyone who consolidates large amounts of refrigerants, detects any problematic mixtures, avoiding costly cross-contamination or residual mixtures in an indicated refrigerant.

Refrigerant Analyzer

A refrigerant recovery and regeneration company uses refrigerant analyzers extensively, and each of their trucks they use is equipped with at least one of these devices. Analyzers are used daily in the field to identify the types of refrigerants, and to record the purity of the refrigerants being recovered used in everything from customer recovery cylinders to cooling shelves; analyzers should also be used during registration in all recovery companies and facilities, to ensure that purity matches the documentation provided by the technician before the refrigerant goes into more intensive laboratory testing (gas chromatography).

Investing in a refrigerant test unit may not be economically practical for most HVAC-R professionals, as the return on investment would take a long time to achieve.

Since many professionals only recover gases for service systems, as long as they recover them in a clean, empty cylinder (to avoid mixing), they would not have a great need to prove the purity or identity of the refrigerant, as it must be clearly marked on the equipment they are repairing.

In a perfect world, this would be true, but as more refrigerants and replacements hit the market, contaminated refrigerant will become more prevalent, especially since not all professionals mark what they are putting into the systems they work on; by passing the systems to other professionals and not having the records on which brand they used or if it was recovered and recycled refrigerant, it could be in the presence of contaminants to the system.

And while refrigerant analyzers can be expensive, they usually range from $1000 to $6,500, depending on the complexity of the device, whether they're too expensive for professionals to buy is quite subjective, there are many refrigerant recovery facilities that will pay a defined price per pound for certain refrigerants with a purity of 95 percent or more.

If professionals use a refrigerant analyzer and check purity before consolidation, they can earn money or receive credits for their next refrigerant purchase. These same recovery facilities can bill for impure refrigerant. In this case, every pound of spoiled refrigerant could cost a professional long-term more than a refrigerant analyzer would cost.

Using an analyzer in the field is also better for the environment and for industry, because refrigerants mixed during the recovery process often have to be destroyed at the recovery facility.

By combating the problem on the front line, with the professional, there will be less environmental impact from destruction, more refrigerant to continue using in the coming years, and lower prices for consumers as supply remains stable.

Using the Refrigerant Analyzer

Like any tool, there are a few key steps and processes to consider when using a refrigerant analyzer, following these steps will result in the most accurate results:

1. Connect the hose to the analyzer before completing an air calibration. The hose should never be connected to a coolant source during calibration, but should be connected to the analyzer.

This allows the internal pump to accurately purge the lines and create the necessary back pressure during calibration. Without the hose connected to the analyzer, calibration may fail or be slightly out of specification.

2. Operate within the operating ambient temperature range of 50° to 120°F.

3. The refrigerant must flow to the analyzer throughout the test. Do not close the cylinder valve or disconnect the hose from the coolant source while the analyzer is completing an analysis. The analyzer requires a constant flow of refrigerant to accurately analyze the gas.

4. Always take samples from the steam port on the low side. Liquid coolant can damage the coolant analyzer and should never enter the device. Sampling the steam port in a system or cylinder will help reduce the likelihood of ingesting liquid coolant.

5. Check that there is coolant pressure in the sample before performing the test. If there is no coolant in the system or cylinder, the analyzer will not be able to receive an adequate sample, which will adversely affect the analysis. Each refrigerant analyzer requires at least 30 psig of vapor pressure to accurately analyze the refrigerant.

6. Know the limitations of the device. Each analyzer is designed to identify or analyze specific refrigerants. If samples are taken from a refrigerant outside of specifications, the results may not be accurate. Have an idea of what refrigerant is expected before analysis. If it is within the specifications of the analyzer, try it.

7. Always use appropriate safety equipment, including gloves and eye protection, to avoid coolant burns when analyzing a system or cylinder.

8. If the analysis yields anything more than expected, handle that refrigerant with caution, as there are counterfeit refrigerants on the market that can cause great harm.

According to this, if the air conditioning and refrigeration professional handles a large amount of refrigerant, for example large contractors with many systems installed, the acquisition of a refrigerant analyzer must be taken into account, however and according to good recovery and recycling practices, refrigerants will have a long service life if there are no damage failures in the compressors and system components.

As a final recommendation, we should use refrigerants seriously certified and acquired from recognized companies that allow us to execute a safe and reliable job.

* Jimy Danelli is an air conditioning and refrigeration maintenance consultant. You can write to the email: [email protected]