The COVID-19 pandemic exposed the need for more information to combat communicable diseases. Research into their causes, controls and cures has skyrocketed and continues as the world tries to protect itself against such viruses.

The COVID-19 pandemic exposed the need for more information to combat communicable diseases. Research into their causes, controls and cures has skyrocketed and continues as the world tries to protect itself against such viruses.

by Dan Jore*

Of course, laboratories work on a variety of projects in addition to contagious diseases and all need different levels of protection to maintain a safe work environment. There is always a need for safe ventilation in the laboratory, regardless of the type of research conducted. However, doubts remain when it comes to specifying these ventilation systems, specifically laboratory extraction systems. What is the appropriate level of protection to specify?

The answer is, it depends. A unique approach to laboratory ventilation is not the answer, as it varies the level and type of research conducted in laboratories. A high school laboratory does not have the same requirements as a laboratory that investigates infectious diseases. Fortunately, there is help.

ASHRAE has shared a post that will help. The classification of laboratory design levels is a guide that addresses:

• Design and operation of laboratories

• Interactions with laboratory airflow control systems (LACS) that provide conditioning

• Ambient air quality control in a laboratory

The classification guide divides laboratories into five levels of increasing risk (Table 1) and describes the type of equipment and controls required for each design level.

The laboratory ventilation design (LVDL) levels are:

| Laboratory ventilation design levels | Air generation potential | Severity of danger | Control strategy | Construction and operating costs |

| 0 | Insignificant | Insignificant | Dilution ventilation | Low |

| 1 | Insignificant | Low (consumer chemistry) | Local extraction dilution and ventilation points | Moderao |

| 2 | Low | Low to moderate | Dilution and disposal, local extraction ventilation, extraction hoods | High |

| 3 | High | High | Dilution and disposal, local extraction ventilation, extraction hoods, special exposure control device (fans) | Very high |

| 4 | Very high | Extreme | Dilution and removal, local extraction ventilation, extraction hoods, special exposure control device | Extreme |

Table 1

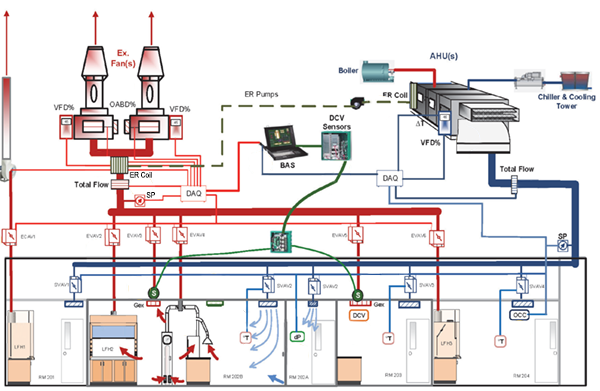

An illustration shows a typical laboratory (Figure 1) with primary air control components and characteristics. The illustration provides a description of these elements, why each is important, and how they can be used at each level of design.

Figure 1: Represents a simplified diagram of a lab and LACS showing critical components. (Image courtesy of ASHRAE)

The ASHRAE guide covers the entire spectrum of ventilation for laboratories. For simplicity, let's focus on the elements to consider when designing the laboratory exhaust system and LVDL. These include fan redundancy, protection of fan drive components from the air stream, a bypass air chamber and regulator, a drive type, a fan discharge, and system height.

Number of extractors: fan redundancy

The number of fans in an extraction system depends on the amount of air being drawn, LVDL's recommendation on equipment redundancy, and the results of a risk assessment conducted during the design process.

The use of a single ventilator in LVDL 0, 1 or 2 laboratories is acceptable and if the laboratory risk assessment is low. The use of a single fan is often with an exhaust dedicated to a single hood or space.

ASHRAE LVDL 3 or 4 recommends equipment redundancy. Redundancy provides a backup fan in the event of a failure to maintain containment in the laboratory. This recommendation is an important consideration as the level of hazard increases along with the potential risk of the work being done on the facility.

Multiple fans offer system redundancy and increased system airflow capabilities when multiple hoods are combined. In addition, multiple fans provide the control option to configure fan operation, reducing operating costs when monitoring risk levels. Ventilation rates for occupied or unoccupied laboratories according to ASHREA 62.1 increase with LVDL or by effectiveness. While safety is the primary concern, different air change rates (ACH) present an opportunity to save on operating costs by reducing treatment to supply air and also saving energy from the exhaust fan by running the fan in stages.

Airflow protection

Staff protection is at the heart of the discussion about LDVL. The discharge into the air of chemicals or hazardous materials from the laboratory poses a risk to people on the rooftop. One aspect that is sometimes overlooked is the handling of exposed air stream components when performing maintenance or repairs. A fan system with a sealed air stream provides a protective cover and gasket for transmission components such as the motor, shaft, bearings, and pulleys to protect against contaminants, but still within the airstream. This design is acceptable when the degree of severity of the hazard is between negligible and moderate, depending on the chemical. Service may require coming into contact with parts that seal the transmission components. The alternative to a sealed air stream is isolated. The transmission components are completely out of the polluted air stream. Two housing designs that feature an insulated air stream are the forked and centrifugal coiled housing designs, allowing for safer inspection or service by maintenance personnel.

Appropriate personal protective equipment should be used when servicing a laboratory exhaust system.

Exhaust fan discharge

Exhaust discharge becomes more critical as the level of design increases. Three different discharge types are available that address design level requirements, increase system height, and produce a high-speed discharge that aids in the dispersion of the contaminated plume.

- A high boom nozzle: it is a designed cone that produces higher discharge speeds and increases the height of the exhaust effluent boom. The height of the effective boom, which includes the height of the fan system and the height of the exhaust effluent boom, is important to prevent contaminated exhaust effluent from being reincorporated into the laboratory or adjacent buildings through compensation air systems or windows.

A high-dilution boom wind band: combined with a high-speed nozzle it drags the outside air, diluting the exhaust effluent and directs the exhaust air stream upwards away from the building. Dilution provides lower levels of downwind contaminant concentration of the exhaust system.

- A variable geometry nozzle maintains a high discharge rate in a variable volume laboratory application without passing air through the bypass air regulator. Energy costs are reduced by decreasing the fan speed and not overlooking outside air while maintaining a high discharge boom height.

Shunt air chamber and shock absorber

Dilution is a control strategy for all five categories of LVDL. It limits the risk of exposure within the laboratory and also reduces the risk of contamination of the discharge escape effluent. Dilution comes at the price of high ventilation rates and, combined with laboratories that often require 100% outside air, is a huge operating expense. This expense is where an exhaust system with a full and bypass air damper can help.

As a system control strategy to reduce operating costs associated with dilution rates and high-level LVDL categories, many laboratories use a variable volume exhaust system. Variable air volume (VAV) laboratory systems save operating costs by reducing the amount of air conditioning expelled during periods when high ventilation rates are not required. The building's laboratory extraction requirements, such as effective boom height and dilution levels, are maintained during these periods using unconditioned air, from outside the building, to make up the difference with a shunt gate and a full.

The open position percentage of the shunt gates of an exhaust system is modulated to balance the laboratory's airflow rates and also to satisfy a constant airflow through the exhaust fan. The VAV control strategy, which includes a full and bypass air regulator, reduces operating expenses and maintains laboratory safety both inside and out.

System height

System height, including stack height, is mentioned as a component of modern laboratory control systems in the ASHRAE guide. It is a safety consideration in laboratory exhaust systems for all LVDL classifications to protect maintenance personnel. Both NFPA 45 and ANSI/AIHA Z9.5 – Laboratory Design Guide, recommend a minimum of a system discharge height ten feet high to protect people on the roof platform from inhaling or coming into contact with contaminated effluent or exhaust particles.

Drive type

Fans used in the laboratory exhaust use one of two types of transmission systems; belt or direct transmission. All LVDL categories discuss control and redundancy strategies to reduce operating costs in laboratories. Lower operating costs are also related to the choice of the type of transmission used in the exhaust system.

Belt drive systems have a motor, fan drive shaft, high-performance bearings and a set of belts and pulleys. The recommendations require the belt drive exhaust system to use a minimum of two belts with a transmission service factor of 2.0. This two-belt minimum provides redundancy and system reliability. If one belt breaks, the remaining belts can withstand 100% of the load without losing containment in the fume hood.

Direct drive systems have fewer components for potential failures and require less maintenance. Fans with a direct drive system are more efficient, eliminating losses through fan belts, pulleys and fan shaft bearings. If combined with a variable frequency drive (VFD) it provides potential savings in operating costs by adjusting the fan speed to match the laboratory's variable flows.

Additional considerations

Other features also play a role in determining the best laboratory exhaust system with the corresponding laboratory LDVL and overall laboratory risk assessment. These include footprint, total height, sound, and weight.

Note: Learn more about laboratory exhaust systems. You can also learn more about LDVL by downloading the Laboratory Design Level Classification. It can be downloaded for free on the ASHRAE website or from TechStreet.

* Article by Dan Jore, Application Engineer at Greenheck. Reprinted with permission from Greenheck Fresh Air blog.

* Article by Dan Jore, Application Engineer at Greenheck. Reprinted with permission from Greenheck Fresh Air blog.