The project carried out by Flutec was also one of the finalists of the 2023 edition of the CALA Awards for best HVAC/R installation in Latin America.

By ACR Latin America

Ciudad Juárez is a municipality located on the northern border of Mexico, in the state of Chihuahua and borders the state of Texas and the state of New Mexico, USA. In the last 35 years, the region has experienced sustained economic and population growth. This is due to the constant increase in industrial activity, in which the manufacture of medical, electronic, and automotive products stand out.

Johnson & Johnson (J&J) has a strong industrial presence in the city that began expanding in 1995. Since then, Flutec has been a consistent provider of HVAC engineering solutions for its manufacturing plants, where most of its production areas are encapsulated in cleanrooms. This 2022-2023 period was no exception, Cordis, a division of J&J, launches its project called BWI in order to build a plant in 8 months to increase its production of cardio catheters and other new products.

The construction, mechanical, and electrical (MEP) and energy control specifications are rigid and come from its J&J World Wide Engineering center. Over the years, Flutec has earned the trust of J&J and has been granted to carry out the HVAC system designs in their entirety at most of its plants in Ciudad Juárez. However, over the years, Flutec has earned the trust of J&J and has been granted freedom to design HVAC systems at most of its plants in Juarez.

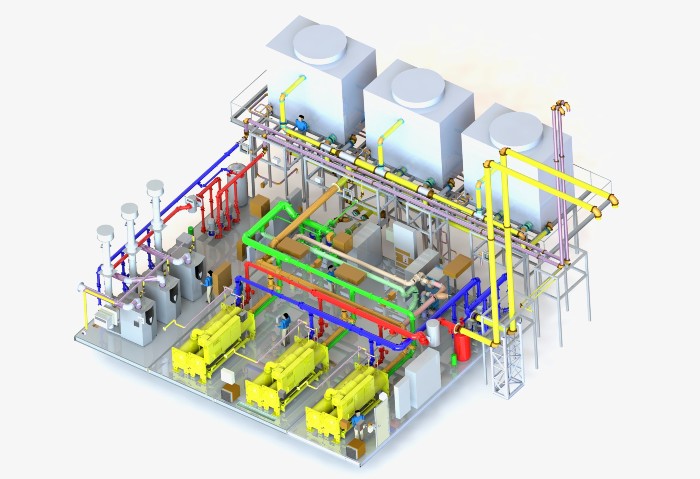

Because of the convenience of fast manufacturing, J&J is requesting that BWI have a Chil-Pak® modular plant. This is the second modular plant to be manufactured for J&J in Ciudad Juárez. The new plant is a 4-pipe hydronic system, equipped with water-cooled variable screw chillers, cooling towers, and hot water boilers and pumping systems. All motors with variable frequency drives and all systems with N+1 redundancy. Your controls with algorithms for optimizing energy use. The modular central plant also has an active hydronic economizer that in the months with low wet bulb provides the necessary ice water for the plant.

The cleanroom is heated by 8 large air handlers equipped with HEPA filters and chilled water coils. It also has three DOAS (Direct Outside Air) handlers to pressurize, filter, add or decrease humidity and control the injection temperature 365 days a year. The humidification system is by an adiabatic process controlled by a precision algorithm developed by Flutec's control engineering team. The cleanroom's air recirculation system also has a smoke evacuation system in the event of a fire and meets the requirements of Factory Mutual Insurance.

Some of the features of J&J's BWI project

Specific requirements from the client:

1. Core Team:

Modular pre-built machine room with high-efficiency variable screw chillers. High efficiency hot water boiler system, chilled water, hot water and tower water pumping systems.

Variable motor cooling tower system for cooling central plant condensers and air compressors.

Oil-free and water-cooled air compressor system.

2. ISO – 8 manufacturing areas including dressing rooms and gown area.

Recirculation handlers with integrated HEPA filters, chilled water coil and pre-filtration, full centrifugal turbines.

Dedicated outdoor air treatment handlers for pressurization, filtration, humidification and de-humidification and temperature control. The humidification system by means of an adiabatic system.

Smoke evacuation system in case of fire.

Process air extraction system (central equipment and preparation of duct intakes for future lines).

Three-step scaled positive pressure control.

Compressed air distribution system with "L" type copper piping for cleanroom.

3. Office Area, Kitchen and Dining Room:

Rooftop handlers and zoned air distribution and control by means of VAV system.

Compliance with ASHRAE 62.1 ventilation standard

4. Automation & Optimization System:

Control system and its algorithms for the entire hydronic system, operation of the handlers, operation of the control of the cleanroom pressures, operation of the central plant, operation of the compressed air system and lighting of the plant

Independent monitoring system for product certification by means of humidity, temperature and pressure sensors.

"Harman Loop" system for optimizing the operation of chilled water. Sustainability & Energy Performance

Data and graphics acquisition system for quality assurance of the artificial climate system of the manufacturing area.

Parameters applied in the project

Management in engineering, sustainability, energy performance, project with future projection.

The work is LEED certified and the HVAC system is very relevant in terms of the well-being of the building's occupants, efficiency in the use of energy, the proper consumption of natural resources and the disposition of materials. All materials used on the site comply with Greenguard certification which ensures low chemical emissions and reduces indoor pollution and the risk of exposure to chemicals. To avoid any environmental contamination, the selection of direct expansion refrigeration equipment was reduced as much as possible and those that do use refrigerant were selected, in this case the chilled water chillers, were selected with R-134A refrigerant approved by the LEED certification. A record has been made of all material dispositions to ensure that they are disposed of in accordance with the legal standards established by the Ministry of Environment and Natural Resources.

The BMS and EMS system monitors the energy consumption of the plant and this allows the system to make automatic decisions that make energy use more efficient: it turns equipment off and on according to the occupancy and temperature requirement; modulates the speed of fan motors and pumps in the equipment according to the air or water flow requirement; It maintains the most efficient setpoints set by design, sends alarms that report setpoints out of range, detects equipment failures that allow personnel to take actions to maintain occupant comfort and/or avoid a catastrophic failure of the HVAC system. Monitoring has allowed us to confirm a central silver efficiency of 0.5 KW per ton of cooling.

The BMS system can also make the decision to activate the system that we know as Free Cooling, that happens on days when the temperature of the wet bulb is low enough and it is possible to take advantage of the water generated by the cooling tower directly in the heat exchange necessary to cool the air; That is, when weather conditions allow it, the system shuts off one of the chillers and modifies the route of the tower water so that it does not pass through the chiller and directly cools the return water that comes from the air handlers. This system reduces the energy consumption of the central plant by 40% for approximately 3 months during the year.

The office area is monitored and controlled by the BMS. Make decisions about the temperature and ventilation of areas. The area is zoned and the temperature of each office can be independently controlled simultaneously. Reducing the energy consumption of the air handler motor by detecting that some areas are unoccupied. This is achieved by the installation of VAV (Variable Air Volume) equipment in the offices.

Projection for the future

The design of the project considered, as part of the client's requirements, to provide additional cooling capacity for an area of 930 m² that would be vacant during the first phase of construction of the warehouse. The capacity of the Chilpak and air compressors was sized assuming that the vacant area would be the expansion of the existing manufacturing cleanroom. Not only was the equipment sized considering the expansion, but the subsystems were installed, leaving connections that in the future would facilitate the installation of the extensions of the ducts, pipes, chilled and hot water, compressed air and control subsystems. At the time of this writing, the construction project in the vacant area is in the preliminary design phase.

For Flutec, BWI has been another project that has been successfully concluded: the systems work efficiently as designed; It was completed in record time, a higher level of quality was complied with endorsed by certifications and validations and because all the customer's standards were reached, but above all, what we are most proud of is that the customer is satisfied with the HVAC solution we provide. We look forward to continuing to work with clients like J&J and continue to face challenges of this magnitude that will allow us to strengthen and grow the deeper fibers that make us the leading HVAC company in Northwest Mexico.