Freeze-drying is a method of preserving food in which different processes converge, such as freezing, vacuum and dehydration.

by Eng. Ernesto Sanguinetti R.*

Food deteriorates or rots by enzymatic action and mainly by the action of microorganisms. Microorganisms that need to feed on organic matter, like all living things, find it in our food. Microorganisms are everywhere, being the most abundant and diverse group of living beings on Earth. Those that influence food spoilage are bacteria, yeasts and fungi.

When bacteria are not in a large enough number they do not cause noticeable changes in the appearance, taste or smell of the food on which they begin to inhabit, however, as time passes and with favorable temperatures, the population of bacteria grows exponentially reaching immense values managing to deteriorate it slowly or quickly.

If bacteria (also yeasts and fungi) could be completely eliminated, food would not have an expiration date, but this cannot be achieved, therefore, methods for preservation are sought whose purpose is to make the deterioration arrive as late as possible.

From experience we know that completely stopping the multiplication and growth of microorganisms is almost impossible, so what we must try to do is that their action is as slow as possible. To achieve this, obstacles are put in their way and this is what conservation methods are based on.

Some methods try to take away the water (without it, they can hardly grow), others subject them to temperatures so low that they become sluggish or have a hard time growing, others subject them to high temperatures to destroy them as much as possible, other methods consist of putting salt, seasonings and others.

Known methods for preserving food

The best known methods to slow the growth of microorganisms are the following:

A-Conservation due to temperature decrease

A1.- Refrigeration: Preservation method that consists of lowering the temperature of food products to a range between 6 ° C and 1 ° C sufficient so that the biochemical reactions of the bacteria present in food become slow and slow to proliferate.

A2.- Freezing: Method similar to the previous one, but where the temperature must be less than 0 ° C, and it is sought that in the center of the product it is reached and maintained at -18 ° C. It is achieved that the water of the food becomes ice, so that the bacteria, not having liquid water, practically can not proliferate and their multiplication is very slow. A3.- Ultra-freezing: It is subjecting the food to temperatures below -40 ° C but quickly (ideally in less than 2 hours). Together with freezing, it is the most effective technique of preservation for a long time and the one that least alters the properties of the product.

B.-Conservation due to temperature increase

B1.- Boiling: Also known as "blanching", it is a preservation method that is usually a previous step to the freezing of vegetables. These are immersed in boiling water to eliminate all possible microorganisms (within them pathogens) and can then be frozen. It is important since the products come from the soil and are carriers of many different bacteria.

B2.- Sterilization: It is a very effective preservation method in which almost all bacteria are killed, including spores, which are the structures that form some microorganisms to protect themselves and that normally cannot be eliminated. The problem is that subjecting food products to such high temperatures (about 115 ° C for a few seconds) alters the nutritional properties by losing nutrients and vitamins. From the microbiological point of view, it is the safest.

The so-called canned or canned use boiling and sterilization to preserve classified and specially cut food products that are hermetically sealed inside generally metal containers.

B3.- Pasteurization: It is similar to sterilization but the products are subjected to lower temperatures (about 80 ° C) and thus the properties of the food are maintained. It should be noted that bacteria die but not spores, so pasteurized products (such as milk) should then be kept inside a refrigerator to minimize their development.

C.- Preservation by fermentation

It is a method of conservation that, paradoxically, favors the development of microorganisms. Only the growth of microorganisms that are not dangerous to health is enhanced.

These prevent the food from being contaminated by pathogens and, in addition, give the product properties that are interesting from the gastronomic point of view. It applies to certain products such as wine, beer, some cheeses. That is why cheese lasts longer than milk.

D.-Conservation by reduction of water content

D1.- Desiccation or drying: It consists of waiting for the food to lose its moisture leaving it exposed to the open air (it can be exposed to the sun) and waiting for it to dry.

D2.-Dehydration: It is called this way when the food is subjected to heat sources to accelerate the drying process. This method only applies to certain products. The objective in both methods is that the microorganisms do not have liquid water.

E.- Conservation by adding some substance or fluid on all or part of the food

E1.- Salting: It is one of the oldest preservation methods and consists of adding salt to the food. Salt (sodium chloride) is "toxic" to microorganisms, as it captures water from food and makes it unavailable to bacteria or feel "salty".

E2.- Smoking: It consists of exposing the food to a source of smoke, something that, in addition to giving it new flavors, allows it to be better preserved thanks to the antimicrobial action of the smoke components generated by burning some woods, accompanied by a slight drying that is also achieved.

E3.- Acidification: As microorganisms are usually very sensitive to acidity, reducing acidification is reducing the pH of the food so that microorganisms cannot feed or multiply. It is achieved by adding vinegar or lemon juice on certain types of food products.

E4.- Pickled: It is a combination of salting and acidification because it consists of applying to the food a bath that is a mixture of salt and vinegar, which allows a good conservation and gives many products a characteristic flavor.

E5.- Addition of sugar: Adding sugar or honey follows the same principle as salty, achieving the preservative action through sugar that bacteria do not like either. It is used in the preservation of jams, compotes, condensed milks, among others.

E6.- Additives: They are chemical substances that are added to food and that are toxic to microorganisms, so they stop their development. Obviously, they must be substances approved for human consumption. Their composition must be certified and guaranteed to be sure that they do not cause any harm to humans.

F.-Preservation by vacuum packaging

It consists of extracting the air surrounding a food that has just been packaged. Without oxygen, bacteria cannot grow.

G.- Conservation by irradiation

Irradiation consists of exposing food to doses of electromagnetic radiation (usually ultraviolet rays, X-rays or gamma rays) that destroy the genetic material of microorganisms, thereby preventing them from developing.

H.- Conservation in controlled atmosphere

Which consists of storing some varieties of vegetable food products inside a room or hermetic chamber and then injecting a gas to mix with the existing air, thus altering the atmosphere surrounding the product. It can be O2, CO2, N2 which are ripening retardants or ethylene which is an accelerant. It is usually combined with refrigeration because it is done inside cold rooms.

I.- Preservation by lyophilization

It is a very effective preservation method that, in addition, maintains the properties of the food in perfect condition for quite some time. We will deal with this method shortly.

Freeze-drying

Freeze-drying also called dehydration by freezing or dehydrofreezing or cryodesiccation or freezing desiccation is another method of food preservation in which different processes converge, such as freezing, vacuum and dehydration. The result is a dry product that maintains almost all the organoleptic characteristics of its original state, such as aroma, taste or taste.

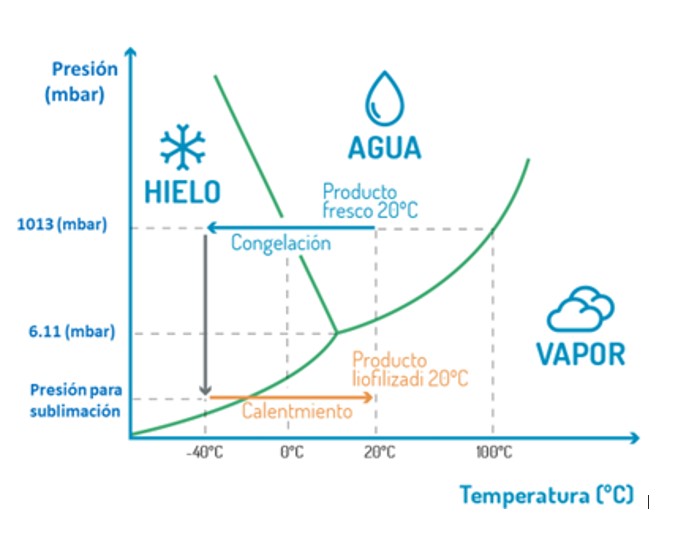

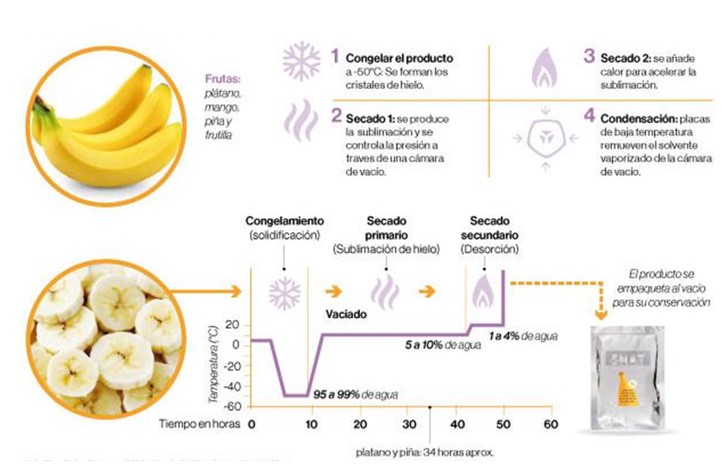

During freeze-drying, the product is first frozen at very low temperatures, quickly, to prevent large ice crystals from forming. It is then subjected to a vacuum process so that the water evaporates without becoming liquid (sublimation). Precisely, by not passing the water through a liquid state, all the properties of color and aroma are maintained, but in dry form.

When the food is to be consumed, it must be rehydrated for about five minutes in warm or hot water. Most freeze-dried products are largely made up of water (for example, some fruits contain between 80% and 90% water).

Eliminating it facilitates the control of microorganisms including some pathogens, which as we have already explained, find in water a necessary means to survive and expand, while extending the conservation of the food product without the need to maintain a cold chain (they can last between 10 and 20 years).

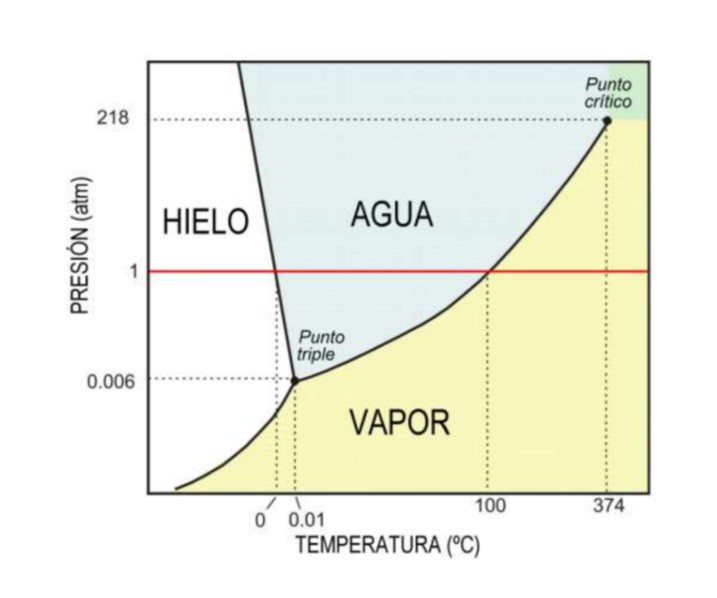

In schematic form, the processes that occur during the lyophilization of water containing a food can be explained using the Pressure – Temperature (P-T) diagram of water, remembering that: 1 atm = 1.013bar = 14.7 psia = 760mm Hg = 29.92 in. Hg = 1.033 Kg/cm2 = 101.3 KPa.

Figure 1

Water Triple Point Conditions: Pressure = 611.73 Pa = 0.00611 bar = 0.089 psia = 0.0061 atm = 4.58 mm Hg Temperature = 273.16 °K = 0.0098°C (considered 0.01°C) =

Figure 2

The main applications of freeze-drying in the food industry are to preserve products such as coffee, tea and other infusion extracts; vegetables and fruits; meat and hydrobiological products; prepared meals; dairy.

In the pharmaceutical industry it is used to preserve medicines. It is a fairly expensive and slow technique compared to traditional drying methods, but it is possible to obtain products of a higher quality since it largely avoids nutritional and organoleptic losses.

In the process of normal dehydration, food only loses between 90 and 95% of moisture, while with lyophilization they lose between 98 and 99% of moisture.

The freeze-drying process was invented in 1906 by Arséne d'Arsonval and his assistant Frédéric Bordas at the biophysics laboratory of the Collége de France in Paris. Then in 1911 Downey Harris and Shackle developed the method of freeze-drying to preserve the live rabies virus, which eventually led to the development of the first rabies vaccine.

Modern freeze-drying was developed during World War II. The blood serum that was sent to Europe from the United States for medical treatment of the wounded required refrigeration, but due to the simultaneous lack of refrigeration and transportation, many of those supplies broke down before reaching their recipients. The freeze-drying process was developed as a commercial technique that allowed the serum to become chemically stable and viable without having to be refrigerated.

Soon, the freeze-drying process was applied to penicillin and bones, and was recognized as an important technique for the preservation of biological products.

Since then, freeze-drying has been used as a preservation or processing technique for a wide variety of products, applied to food processing, pharmaceuticals, restoration of water-damaged documents, preparation of river sludge for hydrocarbon analysis, manufacture of ceramics used in semiconductor industries, to the production of synthetic furs, to the restoration of hulls of historical/claimed ships.

On the other hand, as the freeze-dried food product has significantly less weight compared to the original food, its use has become widespread in the development of food for expeditions, since it allows hikers and especially astronauts to carry more food with less weight and, in addition, with the possibility of reconstituting it with water.

The freeze dryer

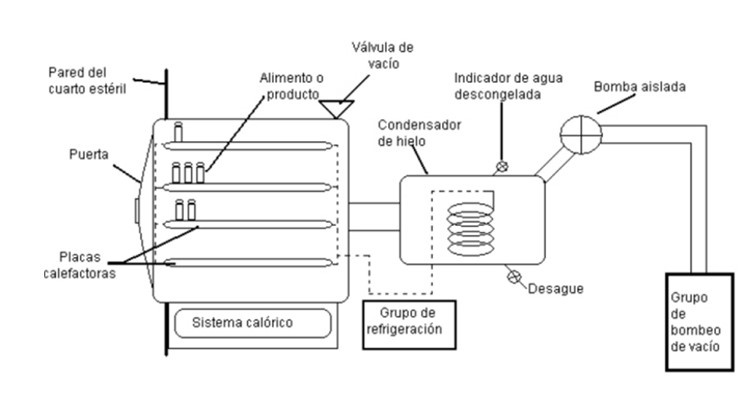

Lyophilization is carried out in a special equipment called a lyophilizer, into which the processed product ready for drying is introduced. Some freeze dryers receive the product already frozen (between -40 ° C and -50 ° C) depositing it on special trays inside the chamber and then with the chamber hermetically closed perform the vacuum process.

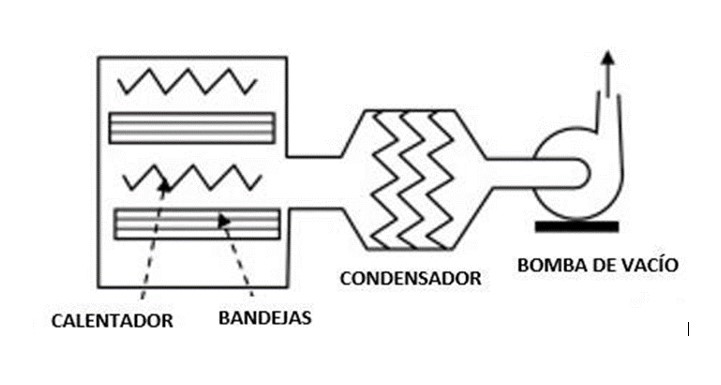

Others perform freezing within the same chamber and then perform vacuum. When the vacuum reaches levels close to 0.001 atm = 0.76mm Hg, heat is delivered to the trays where the frozen products are deposited. Here occurs the sublimation of the ice that exists in the products, that is, it passes directly from solid to vapor without passing through liquid (as shown in the graph above); And that vapor passes through the coils of a condenser to become liquid again that will then be evacuated through a drain located at the bottom of the condenser envelope.

The products that are being dried are kept at a low temperature, until all the water has sublimated. At the end of the process, the lyophilized products are packaged and vacuum sealed, and then stored in dry and clean places.

In schematic form a freeze dryer is shown:  Figure 3

Figure 3

With a little more detail are shown freeze dryers and the process of freeze-drying bananas, mangoes and / or pineapples: Figure 4

Figure 4

Figure 5

Figure 6

Conclusions

As can be seen on what has been treated and explained, lyophilization presents a method of food preservation with a large number of advantages, among which the quality of the final product, the reduction in the weight of the product and the consequent feasibility for its transport and storage stand out, however, to know if it is convenient to use it, it is necessary to analyze the cost vs. benefit because lyophilization is still an expensive process, which involves investment in equipment and a relatively high energy cost. * Mr. Ernesto Sanguinetti R. Manager of the Engineering Division of COLD IMPORT S.A. Lima - PERU.

* Mr. Ernesto Sanguinetti R. Manager of the Engineering Division of COLD IMPORT S.A. Lima - PERU.