Natural refrigerants are here to stay! And with them have emanated new challenges in the HVAC/R industry. The "price to pay" for avoiding refrigerants with high global warming potential is not so low: high pressure, flammability and/or toxicity.

Natural refrigerants are here to stay! And with them have emanated new challenges in the HVAC/R industry. The "price to pay" for avoiding refrigerants with high global warming potential is not so low: high pressure, flammability and/or toxicity.

The search for increasingly efficient systems presents an additional challenge. In this context, choosing the right technologies to optimize the use of natural refrigerants becomes essential. The following five questions can be a good starting point when designing a system:

1. Which natural refrigerant is best suited for my application?

This question is generally easy to answer, considering the different characteristics of each type of natural refrigerant. Hydrocarbons have been shown to be refrigerants suitable for small units, such as beverage chillers or plug-in units, where the refrigerant charge is low enough to make flammability issues less relevant. CO2 has begun to be widely used in applications ranging from centralized systems in supermarkets to air conditioning systems for vehicles. Ammonia has been used primarily in industrial refrigeration for many years, however, its use is now spreading to other applications, such as commercial refrigeration as a secondary fluid. In any case, technological developments allow the use of refrigerants in applications where they had not been used before, so a detailed study of the requirements of each system is recommended before choosing the refrigerant.

2. Where will the app be located?

On the one hand, when using CO2, it is important to know the climatic conditions of the place where the system will be located. Generally, for systems with a gas condenser/cooler located outdoors, the outside temperature can determine the most suitable type of cycle and technology. In practice, if the outside temperature reaches the critical CO2 temperature (31.2 °C), the system will operate in transcritical mode (except for cascade or pumped systems) and therefore the efficiency will be lower. There are different technologies available that can help increase efficiency at high temperatures: parallel compressors, ejectors, FTE...

On the other hand, installing the equipment outdoors and/or out of reach of people when using a flammable or toxic refrigerant (hydrocarbons: flammable; ammonia: toxic and mildly flammable) can facilitate compliance with relevant standards and make the installation safer.

3. What regulations and standards must be respected?

This is one of the most difficult problems to face. As for the regulations, they are currently focused on reducing the impact of refrigerants on global warming, so the use of natural refrigerants is not only not prohibited but is highly recommended. Therefore, special attention should be paid to safety standards.

The safety standards that must be met when using natural refrigerants depend on the application, the type of refrigerant and the territory. There are general standards, such as EN 378 in Europe, and product standards, such as EN 60335-2-89 for refrigeration appliances with a defined refrigerant charge. These mainly include special requirements for systems that use flammable refrigerants, but there are also some requirements for systems with CO2.

This topic has been detailed in several previous posts: blog posts and white papers.

4. What kind of cycle should I design?

The evolution of natural refrigerants has led to different types of systems for each refrigerant.

Starting from the traditional design with CO2 (composed mainly of a compressor, an expansion valve and two heat exchangers), its low efficiency has led to the development of different alternatives.

On the one hand, it is possible to keep CO2 in a subcritical state by designing a cascade or pumping system. In these cases, CO2 is used in a low-temperature secondary circuit: either vapor compression (cascade system), liquid CO2 pumped circuit (pumped system), or both (hybrid system).

On the other hand, transcritical CO2 systems can have single or double evaporation, the latter being called a booster system. The first applicable option for both systems is to add two valves and a vessel to the traditional design, so that simultaneous control of gas cooler pressure and evaporator overheating can be achieved, both of which are essential for optimizing the efficiency of transcritical CO2 systems. However, this solution can be made even more efficient by adding parallel compressors, so that the refrigerant coming from the vessel no longer expands but flows directly to the compressors on the parallel line. If an ejector is added to the three-valve design with parallel compression, the system's performance is further improved, especially in hot climates. In simple terms, an ejector is a device capable of using the potential energy of the high-pressure refrigerant to extract low-pressure refrigerant and bring it to an intermediate pressure, thereby reducing the compression ratio and flow rate handled by the compressor. Working with a three-valve system with a multi-level liquid receiver and zero K superheating (FTE) evaporators is another way to increase efficiency in reinforcement systems.

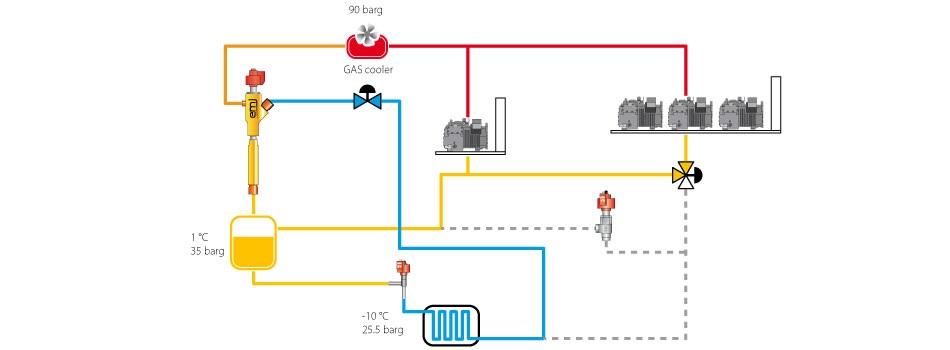

Design of a transcritical CO2 system with ejector

As for propane, the traditional cycle with a compressor, an expansion valve and two heat exchangers usually works even better than with HFC refrigerants. There is another option that consists of performing a multicircuit system, used when the refrigerant load is higher than the maximum load limit allowed by the corresponding safety standard.

Finally, there are different types of systems that can be used with ammonia as a refrigerant and that have been successfully implemented in the market. Ammonia vapor absorption cooling systems are one of the oldest cooling systems, but they are currently not very popular due to their low efficiency. Single-stage compression systems comprise the same components as a traditional cooling system, plus a pump and liquid separator, to ensure that the compressor does not receive any liquid. Two-stage compression systems are the next evolution of industrial refrigeration systems, suitable for low-temperature refrigeration applications, providing high efficiency and low compressor discharge temperatures.

In addition, low-load ammonia systems have emerged in recent years. On the one hand, optimized ammonia systems comprise a traditional industrial refrigeration system optimized by low-load components. On the other hand, a compact ammonia system eliminates large amounts of ammonia stocks and pipes by moving to smaller autonomous systems that are usually placed on the ceiling/floor outside, avoiding any danger due to leaks.

Ammonia is also chosen as a refrigerant in traditional, low-load cascade systems, typically on the high-temperature side, limiting its use to the equipment room.

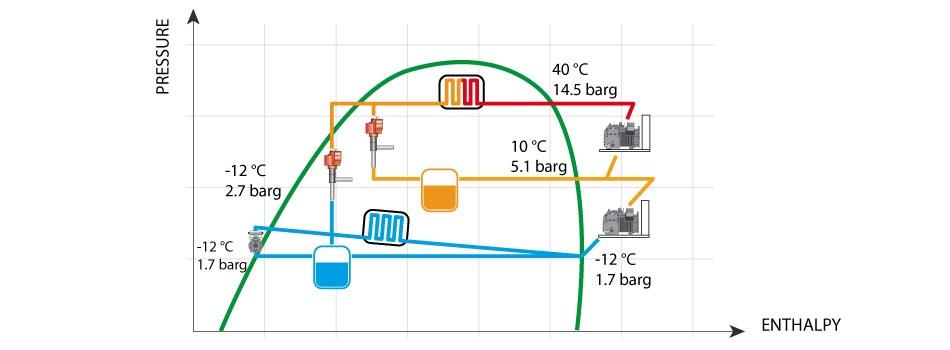

P-H diagram of a refrigeration system with R-717 and two stages

5. Can energy efficiency be improved?

If you have already chosen the cycle to design, you may have also thought about incorporating high-efficiency technologies. These, combined with an efficient control and supervision system, can be key to obtaining a system with optimized performance.

On the one hand, variable capacity compressors with inverter technology provide the best way to avoid inefficient on/off cycles that reduce the seasonal efficiency of the compressor. This means that, at partial load or under low load conditions, an inverter-driven compressor adapts its cooling capacity to system requirements without stopping completely. The ideal solution is to combine variable capacity compressors with electronic expansion valves (EEV), which provide energy savings due to the adaptive optimization of the operating parameters of the system.

There are other components that can increase efficiency and are mainly used in CO2 systems. A subcooler takes advantage of the gas temperature after expansion in the flash valve to cool the liquid coolant before the EEV. An economizer is a type of subcooler that extracts a small amount of CO2 from a specific point in the system and expands it through an expansion valve to cool the main flow coming from the gas cooler. Finally, evaporative cooling in CO2 cooling systems reduces the temperature of the gas cooler by spraying microparticles of water, which means significant energy savings due to the reduction of the power consumed by the compressor. These solutions are particularly suitable for increasing the efficiency of CO2 systems in hot climates.

* Author: Miriam Solana, HVAC/R Technical Knowledge Specialist - Carel Industries.