Second part of this article in which we talk about IoT solutions for commercial automation and monitoring applications.

Second part of this article in which we talk about IoT solutions for commercial automation and monitoring applications.

By Eng. Misael González*

In the first part of this article, presented in the 23-6 edition of 2020, we talked about what sinifies the IoT, its infrastructure and a brief introduction was made to some commercial sectors of application. In this second part we will delve into these sectors and learn about other important concepts.

Transport

In the cold chain, transport plays an important role in the conservation of the precederos and IoT solutions focused on temperature monitoring are designed to preserve the cold chain. However, the optimal state of the products often depends on other variables such as relative humidity or the amount of light.

The devices installed for this application are usually only monitoring and usually have the ability to send temperature readings and other variables of interest through cellular networks to a cloud-based platform that allows to visualize information and process simple alerts in mobile applications. This is a solution based on the object-oriented approach.

Nitin Dahad in the framework of the Global cold chain management solutions conference mentions the importance of keeping monitored the "gaps" that may exist in the cold chain and highlights the sending of alerts and information in real time through mobile communication networks (Dyzle, 2014)i.

Amy Childress in the Unbroken Chain article for Progressive Grocer Habal magazine on IoT-based wireless sensors: "One of the key values of this technology is the ability to receive notifications via email or text messages in real time when a shipment in transit goes outside the ideal temperature range" (McTaggart, J, 2020) ii.

Sale of food

The Retail sector mainly includes supermarkets, however, these buildings are themselves a complex operating system that integrates not only the infrastructure for the cold chain, but also must build an environment designed to generate a shopping experience for the user mostly linked to comfort, this implies environmental conditioning systems that allow maintaining an adequate temperature and lighting.

Maintaining the temperature of a space is actually related to the perception of it, so this implies that variables such as relative humidity and air flow and its temperature are in fact linked to each other.

Regarding the dimensions of this type of establishment, the French Institute of Free Trade (IFLS) and the Organization for Economic Cooperation and Development (OECD) establish the following classification (Miquel Peris, S., & Parra Guerrero, F., 2006)iii:

• Self-service: from 40 m2 – to 119 m2

• Superservice: from 120 m2 to 399 m2

• Supermarket: from 400 m2 to 2499 m2

• Hypermarket: more than 2500 m2

Commonly for this type of applications, control and monitoring solutions designed to reduce the operating costs of the business are contemplated.

In order to make the operation of the establishment more efficient, it is normal for control systems to integrate variables and devices of all kinds, including refrigeration controllers, luminaire control, air conditioning, heating, energy measurement, among others. And it is expected that the variables generated by different devices can be analyzed together so that the system makes the necessary adjustments with as little human intervention as possible. However, as mentioned in chapter 2 (Architecture). The user layer will often require the intervention of the operational part that must make conscious decisions to really obtain benefits. These decisions can be based on the information generated by the system, which is why it is so important that the Application-interface layer of the solution is built among other things for this purpose.

Food Services

This sector comprises facilities in which prepared food is served, this can apply to restaurants, hotels, hospitals and ready-to-eat food stores.

The needs of this sector are focused on complying with local regulations and standards for food preparation.

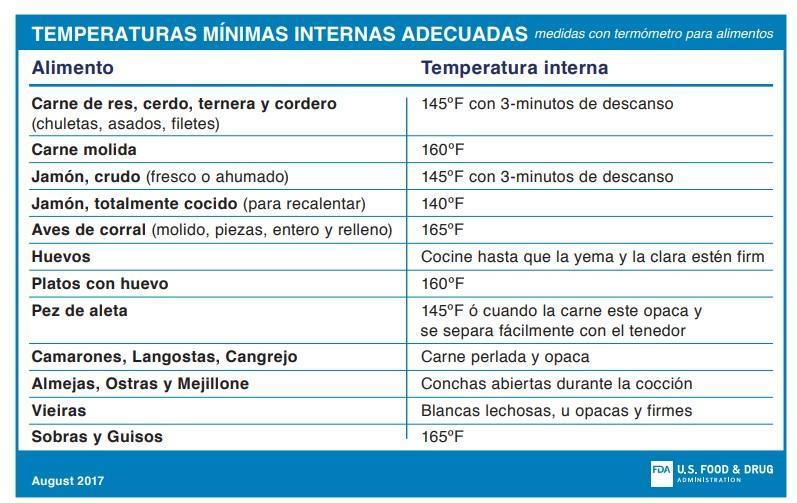

The cold chain plays an important role for this type of establishment that normally has at least one refrigeration chamber for the conservation of raw materials or the finished products themselves. However, local regulations typically set internal cooking temperatures for different types of food as can be seen in Figure 4.1 which refers to the temperatures proposed by the FDA (2020). For its monitoring, innocuous food-grade instruments are required.

Fig.4.1: Recommended minimum internal cooking temperatures. Source (FDA, 2017)iv

Due to the above, the priorities of this commercial sector are basically the monitoring of the temperatures of the products and of the refrigeration and freezing chambers.

The environment intended for the user-client is usually controlled by simple solutions of manual control or mechanical activation. Although, if the environment is complex enough and with the necessary extension, it is possible that the migration to a more robust control solution with connection capabilities that would classify it as an IoT solution is justified. It is also possible that there are many establishments of the same format or chain, in which you want to maintain a uniform operation, in this case an IoT solution would also be justified.

Areas of opportunity for commercial sectors

Once the needs have been grouped and the sectors identified, some important areas of opportunity for IoT solutions in the 4 sectors can be analyzed. In addition, it becomes important to understand its size in Mexico to justify the implementation of this type of solutions.

Food waste

Food waste is an interesting niche opportunity for IoT-based applications. A recent study by Boston Consulting Group (BCG) mentions that 1.6 billion tons of food are lost annually, this is equivalent to one-third of total global food production (Hegnsholt, E., Unnikrishnan, S., Pollmann-Larsen, M., Askelsdottir, B., & Gerard, M., 2020).v.

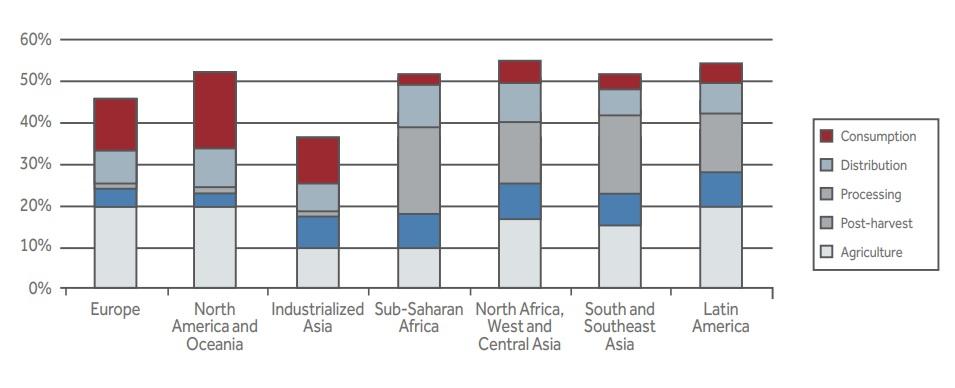

As can be seen in Figure 5.1, it is clear that while industrialized countries tend to waste food mostly during harvest and final consumption, in countries with a low level of industrialization losses are reflected during processing, storage and percentage losses in post-harvest processes involving transportation and immediate storage also increase.

Fig. 5.1: Percentage of loss with respect to initial production. Source: (Rezaei, Maryam & Liu, Bin. 2017)vi.

In Mexico this trend is also present, it is estimated that 72% of food loss occurs during the early stages of the supply chain, while the remaining 28% is produced once the food is already in the hands of consumers and distributors (Secretary of the Interior, 2017)vii.

In addition, costs of 25 billion dollars are estimated for the 21 million tons that are lost per year of the 79 products that represent 81% of the food purchased by Mexicans, whose cost is equivalent to 2.5% of GDP (The World Bank, 2019)viii.

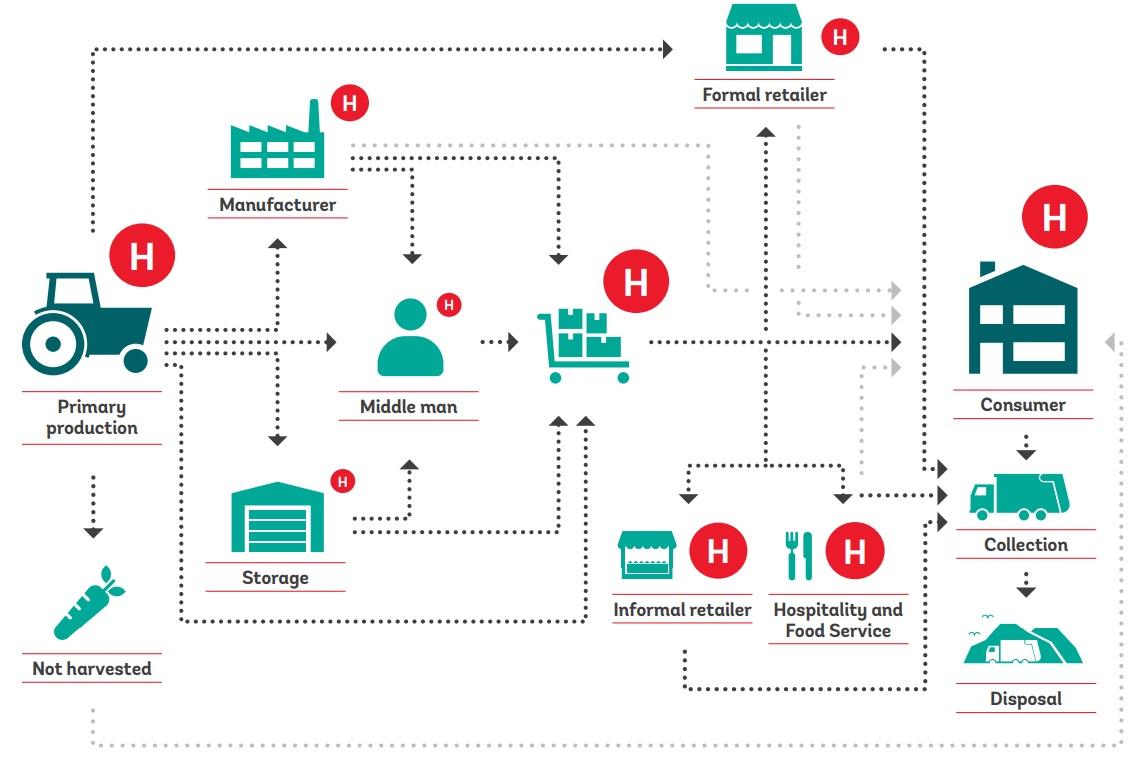

These figures show that, in countries such as Mexico, there are important opportunities in the cold chain that give space to the implementation of IoT-based solutions. Figure 5.2 shows graphically and proportionately the distribution of food loss hotspots along the supply chain in Mexico.

Fig. 5.2: Critical points of food loss in the cold chain in Mexico. Source: (The World Bank, 2019).

To reduce these losses, you can consider improving the very infrastructure of the supply chain, as well as its efficiency.

The supply chain contemplates the storage of food and transport to its destination, which is not always the end user, since its destination can be a supermarket, a restaurant, a hotel and it is even possible that the supply chain of a product is integrated by a large number of steps where it is transported, processed and stored until finally obtaining a finished product.

IoT solutions play an important role in maintaining the cold chain throughout the entire process. One application for these solutions is to measure in real time conditions of temperature, humidity, light and even CO2 levels during transport and storage. This also applies to distribution points where conservation or freezing chambers are kept.

For transportation, you can take advantage of the connectivity of already installed solutions and expand their use beyond the cold chain and use monitoring for security and logistics.

Juan Pablo Leal, Sales Director of Emerson Cargo Solutions Mexico estimates that with the implementation of monitoring systems for the cold chain in transportation, the waste of products in transit in the country due to poor temperature management could be reduced by at least 50%. "This in itself justifies any kind of investment to generate a culture of temperature care and generate greater benefits in the medium and long term."

Considering that in Latin America on average 8% of food loss is generated during transport and post-harvest storage (Rezaei, Maryam & Liu, Bin. 2017), a 50% reduction would represent an opportunity of 1 trillion dollars compared to the 25 trillion losses estimated in Mexico by the world bank.

Energy saving

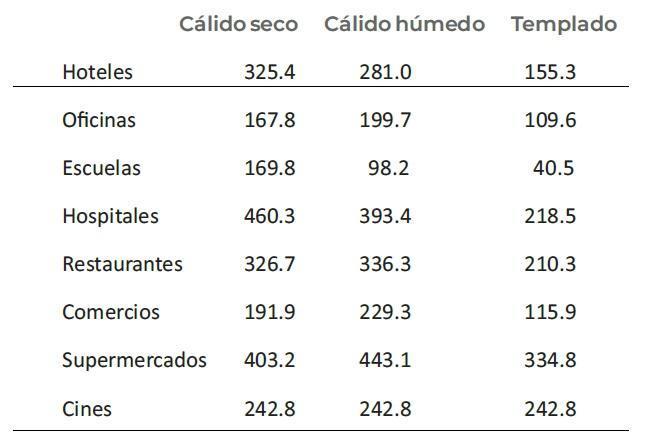

According to data from the Ministry of Energy (SENER) and the National Commission for the Efficient Use of Energy (CONUEE) in Mexico, the energy consumption of residential and non-residential buildings is 126 TWh, exceeding by 11% the energy consumption of the industrial sector, a figure that is considered to be increasing due to the impulse of the commercial sector in the country (Secretary of Energy, 2019)ix.

In the same report it can be seen that the consumption of the commercial area is 66.9 TWh and as can be seen in table 5.1 supermarkets occupy the first place in consumption index per square meter in practically all climates, except in the hot dry climate where hospitals have a consumption of 57.1 kWh / m2 per year higher.

Table .1: Indices of Electricity Consumption used, by type of building and climatic region (kWh/m2-year). Source: (Secretary of Energy, 2019).

Considering these figures, it becomes critical for the operation of many commercial establishments to install a control system focused on energy saving.

In these cases an IoT-based solution also has the advantage of adapting to the needs of different climatic regions and as mentioned earlier in section 4.3, supermarkets, as well as other commercial establishments, are conditioned to the user experience, so the control system must be able to find the balance between comfort and energy efficiency.

Karina Montes, Supervisor of Monitoring Services at ProAct Mexico, estimates that the typical energy saving values for most commercial facilities in Mexico with the implementation of control and monitoring systems is around 15%. "This is achieved in conjunction with a correct program of validation of strategies in which the operational staff must be involved and constantly aligning the objectives with the executive part" It is here where IoT solutions have relevance for data analysis and the constant extraction of information that is carried out without the need for human-machine interaction.

Considering the consumption of commercial facilities is 66.9 TWh and an average price of 0.152 dll ("Mexico energy prices | GlobalPetrolPrices.com", 2019)x, the possible impact of the implementation of these systems in Mexico is approximately 1,525 billion dollars.

Focused maintenance

Maintenance can be seen from three different points of view each more efficient than the previous one: fault-based maintenance, proactive maintenance and benefit-based maintenance (Ron Rajecki, 2016)xi.

In the first scenario, maintenance actions become corrective, that is, actions are taken once a problem has already arisen that will influence operating costs and talking about the cold chain, also in food safety, also generating costs for losses.

Proactive maintenance makes more efficient use of resources by preventing a total failure of a piece of equipment and focusing maintenance actions through performance indicators. In this case, IoT solutions generate the necessary information to obtain these indicators. The information comes from the sensors installed in the system and the historical data allows to detect trends and irregularities that are key to proactive maintenance.

Finally, profit-based maintenance is the optimal point that commercial facilities should aspire to reach, at this point maintenance not only prevents failures, but also improves the very operation of the equipment and the operation of the business. Through the analysis of large amounts of data it is possible to obtain a maintenance model that allows aligning corporate and financial objectives and at the same time makes the experience of users or customers more pleasant. In this case, IoT solutions are used with a markedly semantic-oriented approach, where the information processed and analyzed is the main engine to generate specific actions.

According to the IMF, supermarkets have an average profit margin of 1.2% after tax (FMI Information Service, 2017)xii. Taking this into consideration, maintenance costs have a major impact on bottom line.

In Mexico, according to data from ANTAD, for supermarkets the size of the market is 39,438 billion dollars (Seale & Associates, 2018)xiii. Considering that it is estimated that 0.7% of costs are allocated to maintenance and repairs (The Reinvestment Fund, 2011)xiv, taking into account profit margins and a possible cost reduction of 25% in terms of maintenance expenses, the opportunity for this item is approximately 68.19 million dollars.

Analysis of opportunities

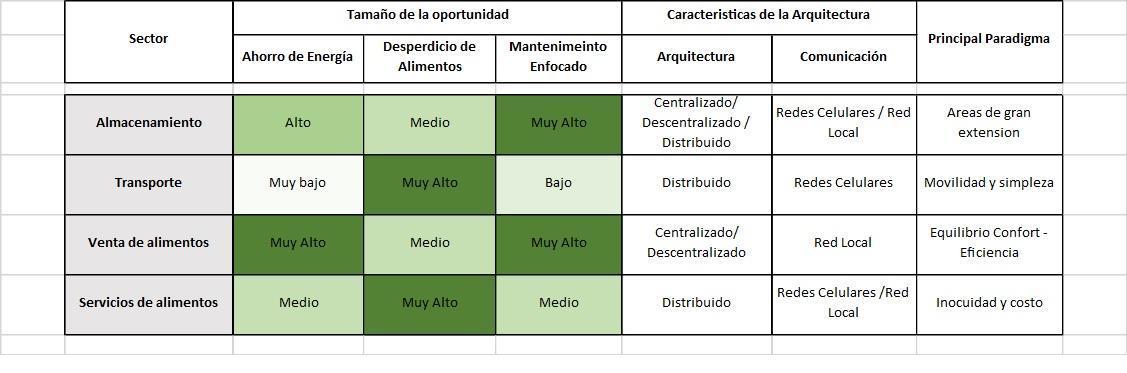

Based on the needs of the business sectors and the areas of opportunity mentioned, it is possible to understand some of the main characteristics of IoT solutions by sector:

Fig. 6.1 Description of IoT solutions by sector.

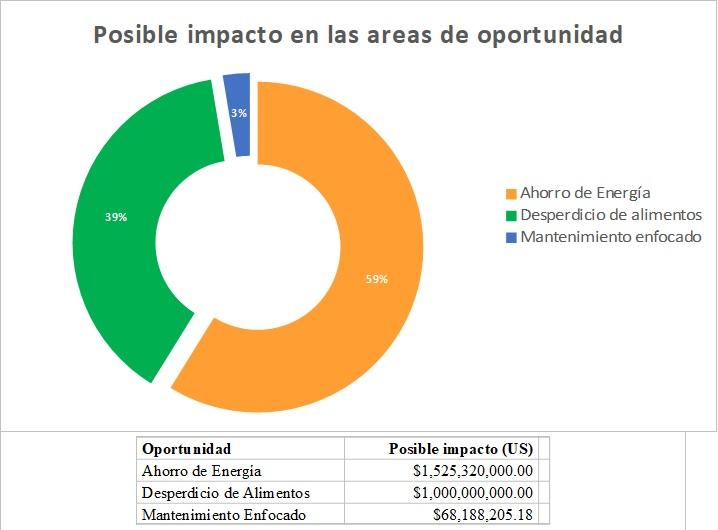

One of the most important considerations when proposing an IoT-based solution is the main paradigm or major "inconvenience to be solved" for each commercial sector. However, the possible impact of installing IoT solutions considering the opportunities mentioned above can be represented in summary in Figure 6.2.

Fig. 6.2 Possible impact of IoT solutions in the main areas of opportunity

As can be seen, focused maintenance seems to be a considerably smaller area of opportunity with respect to the other two items, however, it is important to note that in fact the maintenance factor has a great impact on energy savings and food loss, this can be seen represented in the figure. 6.3.

Fig. 6.3 Impact of maintenance focused on energy saving and food waste

Quantifying this impact is not an easy task because it will depend on the particular conditions of each installation. However, the ultimate goal of implementing IoT-based solutions with respect to these three big opportunities is clearly to reduce operating costs.

There are also other applications that were briefly mentioned in this article such as logistics and security, however, there are other ways to use IoT solutions that currently have some use in the commercial field such as leak detection and it is possible to continue proposing different applications once a control and monitoring system is implemented as long as the solution is flexible and scalable enough.

Migrating or implementing IoT-based solutions as long as you are aware of the needs of each business, is justified and in most cases the right solution should allow you to obtain a quick return on investment.

* Misael González. Application Development Engineer - Emerson, Commercial & Residential Solutions.

Footer.

i Dyzle. (2014). 8 Essentials: Choosing a Cold Chain Monitoring Solution (p. 17). Montreal: Andrea Charles. Retrieved from https://www.iqpc.com/media/1003925/34202.pdf

ii McTaggart, J. (2020). Unbroken Chain. Progressive Grocer, (99), 81-82. Retrieved from https://issuu.com/ensembleiq/docs/pg_0420/80

iii Miquel Peris, S., & Parra Guerrero, F. (2006). Commercial distribution (5thed., pp. 149 – 163). Madrid: ESIC.

iv FDA, Safe Food Handling. (2020). Retrieved 2 September 2020, from https://www.fda.gov/food/buy-store-serve-safe-food/manipulacion-segura-de-los-alimentos-lo-que you-must-know.

v Hegnsholt, E., Unnikrishnan, S., Pollmann-Larsen, M., Askelsdottir, B., & Gerard, M. (2020). Tackling the 1.6-Billion-Ton Food Loss and Waste Crisis. Retrieved 24 August 2020, from https://www.bcg.com/en-us/publications/2018/tackling-1.6-billion-ton-food-loss-and-waste-crisis

vi Rezaei, Maryam & Liu, Bin. (2017). Food loss and waste in the food supply chain. Nutfruit. 71. 26-27.

vii Secretary of the Interior, Mexico wastes more than 20.4 million tons of food each year. (December 9, 2017). The Universal. Retrieved from: https://www.eluniversal.com.mx/english/México-wastes-more-204-million-tons-food-each-year/WorldBank%3B

viii World Bank Group. (2019). A conceptual framework for a national strategy on food loss and waste in Mexico (pp. 19, 26, 27). Retrieved from

https://www.wrap.org.uk/sites/files/wrap/Conceptual_Framework_for_a_National_Strategy_on_Food_Loss_and_Waste_for_México.pdf

ix Secretary of Energy. (2019). Electricity Consumption Of Non-Residential Buildings In Mexico (pp. 1 - 10).

x Mexico energy prices | GlobalPetrolPrices.com. (2019). Retrieved 23 September 2020, from https://www.globalpetrolprices.com/México/

xi Rajecki, R. (2016). https://www.achrnews.com/articles/131434-profitdriven-maintenance-provides value-to-supermarket-clients. Retrieved 18 September 2020, from https://www.achrnews.com/articles/131434-profit-driven-maintenance-provides-value-to-supermarket clients

xii IMF Information Service. (2017). Grocery Store Chains Net Profit. IMF. Retrieved from https://www.fmi.org/our-research/supermarket-facts/grocery-store-chains-net-profit

xiii Seale & Associates. (2018). Mexican Supermarkets & Grocery Stores Industry Report (p. 1). Retrieved from http://mnaMéxico.com/wp-content/uploads/2018/07/Supermercados-Inglés-Final.pdf

xiv The Reinvestment Fund. (2011). Understanding the Grocery Industry (p. 10). Retrieved from https://www.reinvestment.com/wp-content/uploads/2015/12/Understanding_the_Grocery_Industry-Brief_2011.pdf