Technical aspects to take into account when using equipment to control the conditions of high enthalpy.

Technical aspects to take into account when using equipment to control the conditions of high enthalpy.

by Alfredo Sotolongo*

The most economical energy to produce is the one that is saved!

In several previous columns I have insisted on humidity control, since in most of our countries there is a condition of high enthalpy, which we must control as efficiently as possible. Especially in 100% outdoor air applications.

When we apply direct expansion units where we use hot gas reheating, it is easier to obtain the desired conditions of the supply air when leaving the reheating coil. However, when what is available for the cooling coil is cold water, then reheating must be applied as efficiently as possible.

In one of the previous articles I explained the application of "Heat Pipe" which, in most cases, is enough to maintain the required conditions. However, this overheating is only sensitive, keeping the dew point constant. When the dew point value is critical, then it is important to ensure that air-to-air enthalpy exchangers are used that contribute to increasing the dry bulb while reducing the dew point.

Hot gas reheating is also used along with enthalpy wheels as featured in the AAON unit. In these cases, the enthalpy wheel helps reduce the size of the unit by pre-cooling the outside air entering the unit. After the air leaves the cooling coil, it is reheated through the hot gas or using Heat Pipe, bringing its conditions close to the neutral air condition 75⁰F/62.5⁰F.

The optimal application to achieve low dew point conditions without using external energy is using double enthalpy wheel. The cooling coil can be cold water or direct expansion.

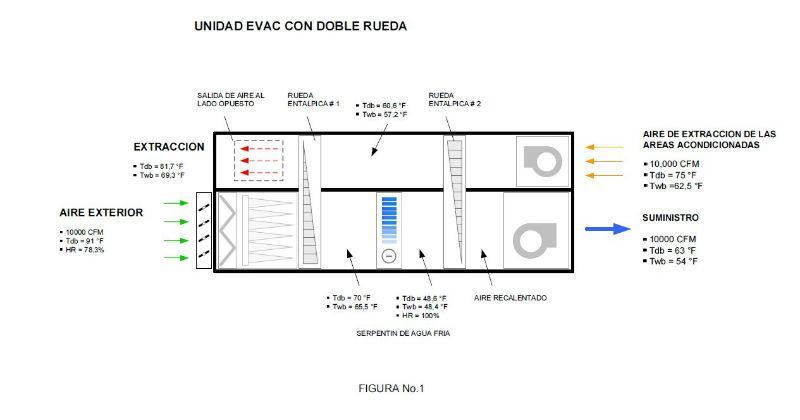

Please refer to Figure 1, where EVAC achieves this purpose in its air handling units using double air-to-air enthalpy exchangers. The first manages to improve the conditions of the outside air to minimize the capacity of the cooling coil and the second is used to reheat the air that comes out of the saturated coil very close to 100% relative humidity and bring it to the desired outlet conditions reducing the dew point of the air. In addition, the #2 exchanger pre-cools the exhaust air that comes from the conditioned areas.

Figure 1 shows the process that occurs within the unit based on the following conditions:

a) Outside air volume = 10,000 CFM

b) Condition of outside air entering wheel #1: 91⁰F/78⁰F

c) Condition of the exhaust air of the conditioned area entering wheel #2: 75⁰F/62.5⁰F leaving at 60.6⁰F/57.2⁰F

d) Condition of the outside air leaving pre-cooled wheel #1: 70⁰F/65.5⁰F, entering the cold water coil. Exiting the cold water coil at 48.6⁰F/48.4⁰F and entering wheel #2 by reheating the air to the required conditions of 63⁰F/54⁰F.

Legend:

AS = Supply air.

AE = Outside air.

AEX = Exhaust air from conditioned areas.

BS = Dry bulb.

BH = Wet bulb.

HR = Relative humidity.

BS/BH = Represents the air condition: Dry Bulb/Wet Bulb

By using the two wheels as can be seen in Figure 1 it is possible to supply the air at a lower dew point without the need for external energy. Through the enthalpy wheels, the air is pre-cooled and reheated as needed. The control system shall modulate the flow of water through the cooling coil to maintain design conditions.

It is important, in cases where the dew point is critical, to ensure that by applying two enthalpy wheels the conditions required for the supply air are achieved.

If you need more information on any of the topics covered in this column, please contact me at the mail: [email protected]

* President of Protec, Inc., is certified as a professional engineer in Puerto Rico and the state of Florida; has more than 40 years of experience in the application and sale of systems and equipment for energy conservation. He is a member of ASME (American Society of Mechanical Engineers), AEE (Association of Energy Engineers), ASHRAE and was president of the Miami chapter of that association.