Deep technical analysis on this kind of alternative that is implemented as a refrigerant for different systems and solutions in the sector.

Deep technical analysis on this kind of alternative that is implemented as a refrigerant for different systems and solutions in the sector.

by Ernesto Sanguinetti Remusgo*

Because of the damage they did to the terrestrial ozone layer, the total elimination of the manufacture/sale of CFC refrigerants has already occurred. The gradual elimination of the use of HCFCs for developing countries has been taking place and has its limit in 2030 (although between 2031 and 2039 very small quantities can be imported for special cases, but after that last year there will be total elimination).

On the other hand, HFC refrigerants with high GWP that contribute to global warming (greenhouse effect) have a phase-out program that has already been taking place in developed countries for a decade, and in much of that time refrigerant manufacturers together with manufacturers of refrigeration and air conditioning equipment have been working to develop refrigerants with a lower impact on global warming. For developing countries, called group A5 according to the Montreal Protocol, there is another program to phase out HFCs (each country will develop its program that will probably begin from 2024) and in the meantime we will be accommodating to the known fluids and those that appear, having as a condition that they do not damage or damage very little to our planet.

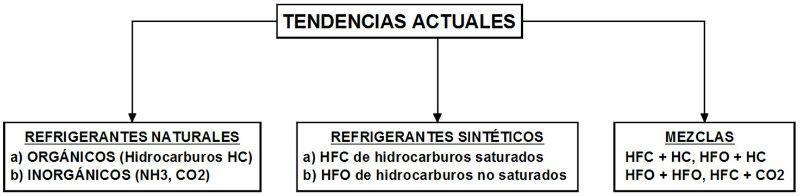

While final substitutes for refrigerants are still being analyzed and tested in most applications, the main contenders belong to one of these groups:

- Natural refrigerants (which can be Organic like HC Hydrocarbons and Inorganic like Ammonia NH3 and Carbon Dioxide CO2).

- Synthetic refrigerants (which can be HFCs achieved from saturated hydrocarbons and HFO or Hydro Fluoro Olefins achieved from unsaturated hydrocarbons).

- There is a third group as a consequence of the previous two because they have begun to use mixtures of them, with some good results. Graphically we show those 3 groups:

Figure 1.

- We will deal with one of those natural refrigerants that is a hydrocarbon (HC): Propane or R-290

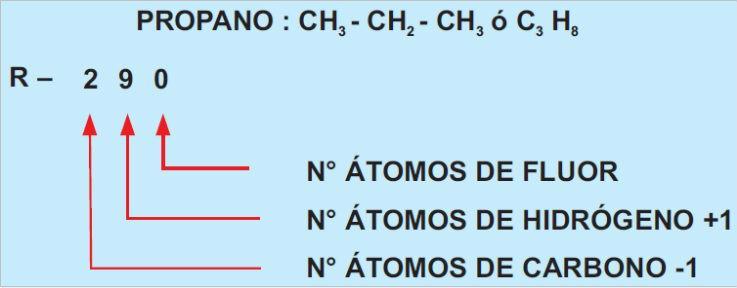

The STANDARD 34 of the ASHRAE to identify Natural Organic Refrigerants that is the group to which Propane belongs, says that after the letter "R" up to 4 digits can be used:

- First digit, from right to left = number of fluorine atoms in the compound.

- Second digit to the left = number of hydrogen atoms plus 1.

- Third digit to the left = number of carbon atoms minus 1 (not used when equal to zero).

- Fourth digit to the left = number of double bonds, when it exists. This is for unsaturated halogenated synthetic refrigerants (the digit is not used when it is equal to zero).

- If you look at a lowercase letter after the numbers, it is an isomer compound.

Isomerism is a property of those chemical compounds that, with the same molecular formula (undeveloped chemical formula) of the same amounts of atoms that make up their molecule, but that these atoms can be accommodated in different ways presenting different chemical structures, and therefore, they have different properties. That is why these compounds are called isomers. There are no isomers in the case of Propane.

Figure 2.

The use of propane as a cooling fluid is increasing because it has several advantages:

It is a natural fluid, does not damage the ozone layer (ODP =0), produces negligible global warming (GWP less than 5), is cheaper, compared to other refrigerants less amount (by weight) is needed as a load in the systems, it is compatible with all commercial lubricating oils (but always consult with compressor manufacturer), it has comparatively lower pressures and working temperatures, decreases energy consumption as well as maintenance cost in the systems, is very stable being compatible with metals and other elements that are used in refrigeration circuits and increases the useful life of the systems.

But it has disadvantages:

It is flammable, for the service requires trained personnel, requires control mechanisms and special protection to avoid sparks.

Because it is flammable, but not toxic, it should be taken into account that the ASHRAE has already classified it as a refrigerant belonging to group A3.

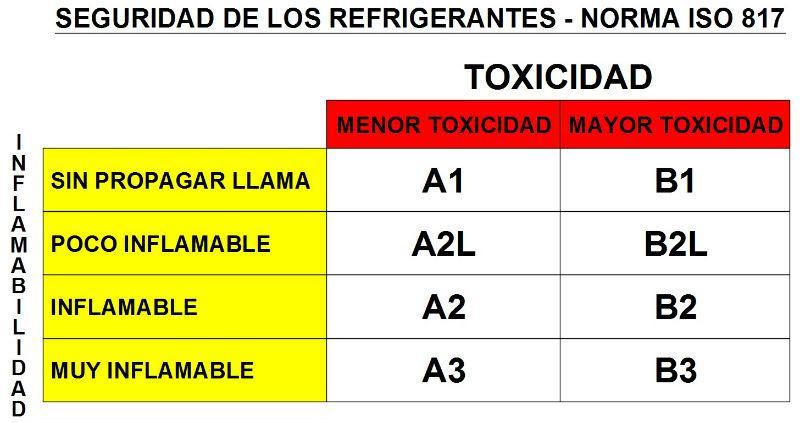

This classification used for all refrigerants obeys the following safety standard that uses a letter followed by a number:

Figure 3.

The categorization based on toxicity is done with the "A" and with the "B" depending on whether or not toxicity is identified in a person at a certain concentration and is of two classes:

Class A: In which no effects of chronic toxicity are observed when exposed to concentrations equal to or greater than 400 ppm.

Class B: In which chronic toxicity is observed when exposed to concentrations below 400 ppm.

The categorization based on Flammability is made with the numbers "1", "2" and "3", depending on the speed of propagation of a flame, and is of 4 classes:

Class 1: No flame propagation occurs in tests in air at 60ºC and standard atmospheric pressure.

Class 2L: Same as class 2 but with a laminar flame velocity of less than 0.10 m/s.

Class 2: It presents flame propagation in tests at 60ºC and atmospheric pressure, but has a LII greater than 3.5% by volume and a heat of combustion less than 19,000 kJ / kg.

Class 3: It presents flame propagation in tests at 60ºC and atmospheric pressure, but has a LII less than or equal to 3.5% per volume or heat of combustion greater than or equal to 19,000 kJ / kg.

To be taken into account

- Due to flammability, propane and HFOs differ significantly. Even though some HFOs are flammable, they have a very high LII, so a large leak must occur before turning on; and when they are turned on they do not emanate much heat and tend to burn slowly. These properties are so special that ASHRAE created the flammability classification called 2L. Now it applies to HFOs (HydroFluorOlefins) and mixtures between those fluids or mixtures of other refrigerants with those fluids, because they have very low flammability.

- Lower Flammability Limit (LII), is the minimum concentration of gas in the air below which fire is not possible. Upper Flammability Limit (LSI), is the maximum concentration of gas in the air above which fire is not possible.

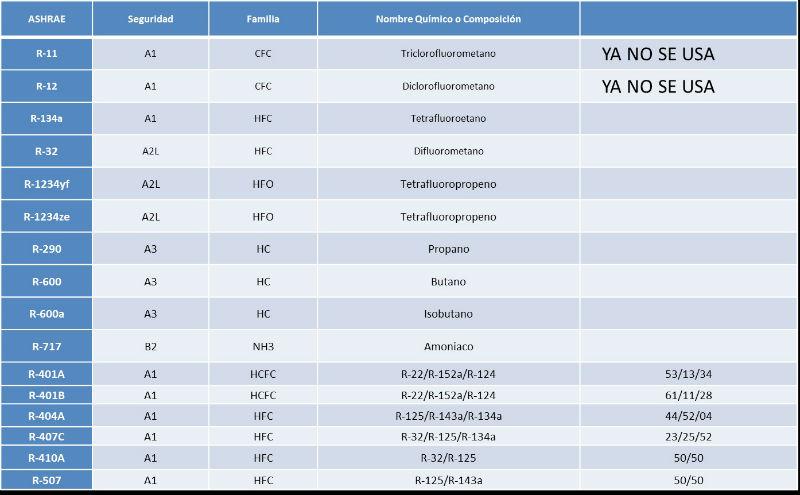

We show for comparison purposes the safety characteristics of some refrigerants within which is PROPANE (R-290):

Table 1.

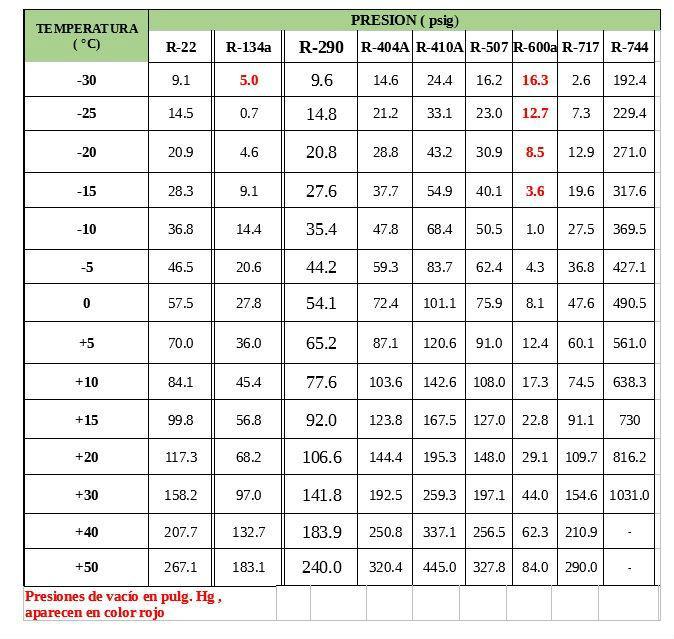

We show the Tables of Pressure vs. Temperature for comparison purposes of R-290 (Propane) with other refrigerants, being from this point of view very similar to R-22:

Table 2.

As flammable refrigerants, for both Class A2 and Class A3 refrigerants, safety codes or regulations currently severely limit the amount, in weight, to load a system; effectively banning them in most large-scale applications. In the United States of America and Europe, commercial refrigerators and freezers have limited the load for A3 refrigerants (propane among them) to 150 grams. In Europe, manufacturers of refrigerated furniture for commercial application are pushing for that limit to rise to 1 or 1.5 kilos.

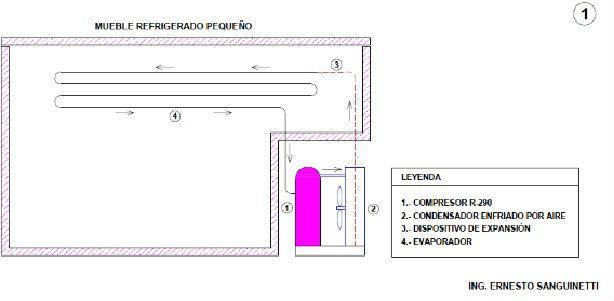

With the aforementioned limitation it is sufficient to cool domestic refrigerators or small beverage preservatives or food displays of a supermarket, but it is practically insufficient for larger refrigerators without a door or with a glass door commonly located in the aisles of dairy, vegetables or frozen food in supermarkets, because even having self-contained refrigeration equipment, as shown in graph N°1 with air-cooled condenser, they require more refrigerant load.

Figure 4.

If they are connected to a compressor plant located in a remote Engine Room having an air-cooled condenser even further away, the amount of refrigerant charge required will be greater and will inevitably be outside the permitted limits.

By having these restrictions appear the "ingenious" solutions of the Engineers to be able to use little refrigerant.

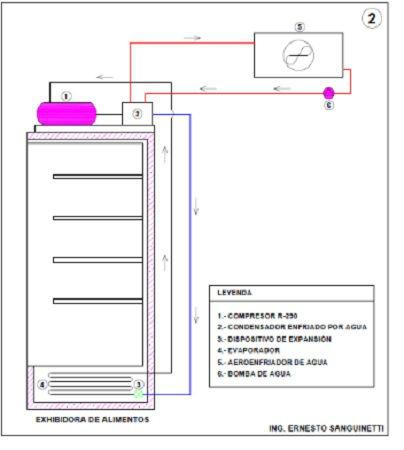

A solution proposed and already in use is the use of the condenser type plates cooled by water as in graph N°2 as would be the case of a dairy or beverage display, with doors or without doors to the consumer. This solution requires the use of a coil with copper tubes, aluminum fins and fan (s) that is an "aerocooler", in English they call it "dry-cooler", to cool the water and use a closed circuit with a pump that recirculates it (circuit in RED color). The R-290 refrigerant charge is significantly reduced. The "aerocool" is located outside the furniture and even more so outside the sales premises.

Figure 5.

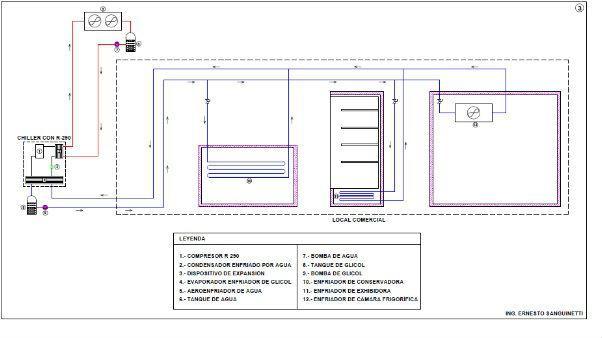

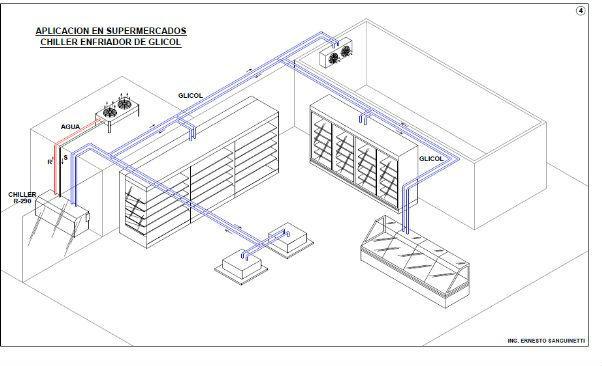

Graphs 6 and 7 show more ingenious and daring solutions because the R-290 refrigerant load is restricted to that existing only in the "chiller" that is located in an engine room or in general in an environment outside the premises or the sales room to the public.

That "chiller" has a compressor for R-290, a water-cooled plate condenser, a thermostatic or electronic expansion valve and a plate-type evaporator. The refrigerant is Propane or R-290. The propylene glycol after cooling is pumped and distributed to each preservative, display case, island or cold room that can be at different temperatures, to then be collected and put together again returning to the "chiller" to cool and work in closed circuit (circuit in BLUE color).

On the other hand, like the case explained above, the water circuit that serves for the condensation of Propane is graphed in RED, also having its "aerocool".

Figure 6.

Figure 7.

Meanwhile, with HFOs, which are low-flammable, efficient synthetic refrigerants with a global warming potential also much lower than HFCs, tests are being done to be used in domestic refrigerators, commercial refrigeration, air conditioning and others.

* Eng. Ernesto Sanguinetti Remusgo, Engineering Division Manager -COLD IMPORT S.A.- Lima – PERU. [email protected]