Analysis of the different types of existing lubricants for compressors, both in refrigeration and air conditioning.

Analysis of the different types of existing lubricants for compressors, both in refrigeration and air conditioning.

by Ernesto Sanguinetti*

1.-Types of lubricants: In general terms they can be classified into: solid, semi-solid, liquid and gaseous.

A.-Solids: Talc: It has a density between 2.7 and 2.8 gr/cm3. Its color can vary from apple green, gray or white to silver. It shines with a luster between pearly and fatty.

Graphite: It is black and opaque, has a metallic luster and a density of between 2.09 and 2.2 gr/cm3. Being very soft (hardness between 1 and 2) stains any element that touches and has a greasy or elusive touch. It is the only non-metallic material that conducts electricity well; however, unlike the other electrical conductors, it transmits heat poorly.

B.-Semisolids: Fats: They are dispersions of oil in soap. They are used to lubricate areas impossible to grease with oil, either due to lack of conditions for their retention or because the atmosphere of dust and dirt in which the machine is located advises the use of a pasty lubricant. One of the most important characteristics of fats is the drip point, that is, the minimum temperature at which the grease contained in a special container begins to drip through a hole located at the bottom. It is very important, since it allows to know the maximum temperature of use. Depending on the soap that forms them, fats can be calcium, sodium, aluminum, lithium, barium.

Some features and applications are as follows:

Calcium fats: They have a buttery appearance, are insoluble in water, resist 80 ° C and are very economical. They are used to lubricate bearings located on car chassis and bearings of machines working at low speeds and at less than 75 °C.

Sodium fats: They have a fibrous appearance, emulsify in water, resist 120 ° C and are little fuse. They are used for bearings where there is no danger of contact with water.

Aluminum greases: They are fibrous and transparent, insoluble in water, very adhesive and very stable. They resist up to 100 °C. They are used in gimbal joints, chains, gears and cables, gears and chains; and in centralized greasing systems.

Lithium greases: They are fibrous, resist water quite well and can be used from -20°C to 120°C. They are used for general applications (bearings, pivots in automobiles), containing, if necessary, molybdenum disulfide.

Barium fats: They are fibrous and more resistant to water than lithium, and their maximum temperature of use is 180°C. They are for general purposes.

C.-Liquids: Generally called lubricating oils, they are divided into four subgroups.

Mineral oils: Obtained from the fractional distillation of petroleum. Based on the crude oil from which they are obtained, they can be: paraffinic base, naphthenic base (the most used) and aromatic base.

Oils of vegetable and animal origin: They are also called fatty oils and among them are: flax oil, cotton, rapeseed, olive, bacon or pork, beef, glycerin.

Compound oils: Formed by mixtures of the first two, with the addition of certain substances to improve their properties.

Synthetic oils: Those that have been obtained exclusively by synthesis in the laboratory instead of using products extracted from petroleum or other natural substances. The synthesis of "ester" in the laboratory makes it possible to choose in advance the characteristics to be obtained in the lubricant. For example, low fluid polymers, called synthetic hydrocarbon oils, can be obtained from olefins by polymerization; from fatty acids and alcohols, by esterification, synthesis esters are obtained; of ethylene oxide or propylene, by polymerization, polyglycols are obtained. Its components are not altered over time, maintaining their quality.

There are several types of synthetic oils: alkylbenzene, polyolester, polyalphaolefin and polyalkyl glycol. The most widely used are polyalkylene glycol (mainly in automotive refrigeration/air conditioning) and polyolester.

D.-Gaseous: Pressurized gases that are introduced between the faces of moving bodies. When injected under pressure they are used to lubricate elements that require very precise movements such as supports that allow the rotation of large telescopes.

2.-Beginnings of lubrication: natural grease began to be used as a lubricant for millennia and the oldest uses date back to about 4,000 years before our era.

In those distant times, for example, the Egyptians used grease to solve friction problems in their carriages and in their construction machinery used, among other things, to build the famous pyramids.

Those first lubricants were animal fats, but then lubricants were made that contained lime mixed with animal fats and in others with vegetable oils. This type of lubrication was used until the eighteenth century, where the first greases made from mineral oils appear, developed and used as effective lubricants in the wagons of the mines and in the industrial machines that at that time worked quite slowly.

These fats were used until the early twentieth century. Today they are still used for various applications in some parts of the world; but throughout the twentieth century and with the development of steam engines, motor vehicles, industrial and agricultural machines, refrigeration machines, there was a greater need for grease and a growing need for oils.

This is how the oils produced from metallic soaps of sodium, aluminum and barium, among other elements, arise. There was a very varied range of greases and oils as each product was created according to a specific use: for axles and pistons, sprockets, steering controls, carriage wheels, wagons and wagons, transmissions, clutches, etc.

Modern lubricants

Around 1950 a so-called "multipurpose" grease was introduced, made from lithium. The appearance of this product brought some skepticism among users but some years later it became the most used lubricant for motor vehicles and industrial machines.

Even today lithium grease is used in the industrial world. The lubricants currently used are mostly of mineral origin and are extracted from crude oil. As mentioned, before oil was known, oils of animal origin (whale, pig, beef, sheep, etc.) and of vegetable origin (olive, sunflower, castor, etc.) were used.

The lubrication capacity of animal and vegetable oils is greater than that of mineral oils, but they have the serious disadvantage of their poor stability, they oxidize and decompose easily producing acidic substances that attack metal surfaces.

Therefore, in the current lubrication, mineral oils are preferably used. In the refining process of crude oil, the following compounds are obtained at different temperatures: gasoline, diesel, kerosene, waste, oils, etc. Finally, various chemical compounds are added, according to the characteristics and use that you want to give to the lubricant.

Lubrication is basic and necessary for the operation of almost all the machinery used in the world. Without lubrication, the machines would not work, or if they do it would be for a short time before being damaged.

The lubricant industry is constantly improving and changing its products as the requirements of modern machinery evolve and new chemical and distillation processes are discovered. Having the basic knowledge of lubrication technology helps to choose the best lubricants for every need.

Biotechnology is the future

Synthetic and biosynthetic lubricants are relatively new to the industry and their high production costs prevent them from being in majority use so far. A synthesized material is a compound that is produced by chemical combination or by the construction of complex molecules derived from less complex molecules. By definition, a conventional synthetic lubricant is a lubricant designed and made in a laboratory to better serve purposes that previously could only be served with products extracted directly from petroleum.

A biosynthetic lubricant comes from a biodegradable and renewable base. They are more efficient because mineral oils are a complex mixture of naturally produced hydrocarbons (crude oil) and biosynthetic oils are products made from biodegradable bases and mostly with the same molecule in configuration and size.

Additionally, biosynthetic oils have a high index of natural viscosity that makes them very stable in the face of changes in temperature, improving their ability to perform in a wide range of temperatures which translates into the lubricant "thinning" less with high temperatures, this is not to decrease its viscosity much, (for example with the hot engine of a vehicle or in the discharge of a compressor) and that it "thickens" less in low temperatures, this is that it does not increase its viscosity much, (with the cold engine of a vehicle or in the evaporator of a refrigeration machine).

3.-Lubrication in refrigeration and air conditioning compressors: the first thing we must bear in mind is that the compressor manufacturers used in these applications always specify the type of oil used by each model produced; therefore we must stick to complying with them.

One of the most common mistakes occurs when the service is performed and the appropriate oil is not used to replenish or add oil to the compressor, because damage to the system can be caused due to non-compatibility with the refrigerant and system components. In addition, in hermetic and semi-hermetic compressors, the oil is in intimate contact with the windings of the electric motor, therefore, it must have good compatibility and stable thermal properties.

The lubricating oils remain in the compressor crankcase, however inevitably a small amount will circulate to the rest of the refrigeration circuit. The lubricating oil must be able to withstand both a high temperature in the compressor discharge and a low temperature in the expansion valve and evaporator. It must be sufficiently soluble with the refrigerant to be able to return to the compressor, so that over time, it does not run out of its lubricating oil load, which could generate a mechanical failure.

Compressor oil classes

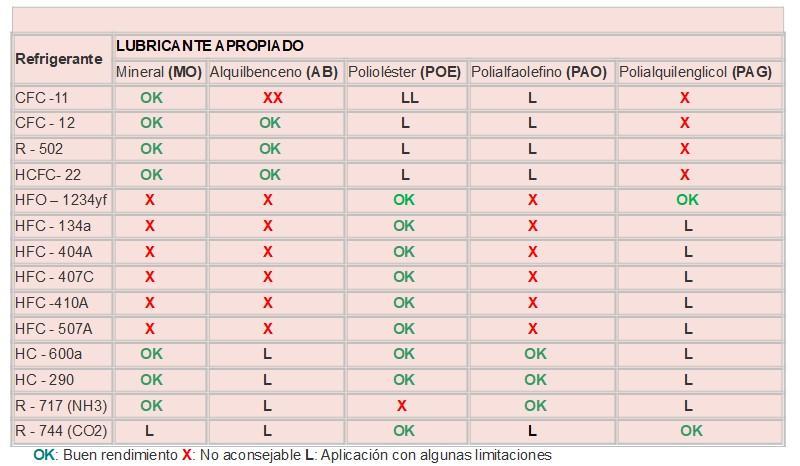

There are five classes or categories of lubricating oils:

* Mineral Oil (MO)

* Alkylbenzene Oil (AB)

* Polyolester Oil (POE)

* Polyalphaolefinic Oil (PAO)

* Polyalkyl Glycol Oil (PAG)

CFC refrigerants used mineral and alkylbenzene oils to lubricate compressors. HCFC refrigerants also use them and from that group until now R-22 refrigerant is still used. This has changed today, with the introduction of new substitute refrigerants, which are not miscible with traditional mineral oils, and synthetic type oil needs to be used to achieve proper miscibility and oil return.

An important feature of synthetic lubricating oils, such as POE and PAG, is that they are much more hygroscopic than mineral oils. POE oils are saturated with approximately 1000 ppm (parts per million) of atmospheric moisture, compared to 100 ppm for mineral oils. PAG lubricating oils are more hygroscopic than POE lubricating oils.

The following table should be taken only as a guide to show the compatibility between oils and refrigerants, because it is the compressor manufacturer who recommends which oil to use:

Table 1.

Note: The second part of this article will be found in issue 1 of 2020.

* Ernesto Sanguinetti, Manager of the Engineering Division of Cold Import - Peru.