CO2 technology in industrial refrigeration, a reality in Latin America.

CO2 technology in industrial refrigeration, a reality in Latin America.

by Eng. Mauricio Baena*

With the entry of the implementation of kigalli's amendment this year in Europe, and the respective ratification of Mexico, Costa Rica, Panama, Colombia, Ecuador, Peru, Uruguay, Paraguay, and Chile of the same amendment, makes these countries look at a 5-year panorama of the need for implementation of refrigerants with GWP below 150 in new facilities. Among the options that designers, consultants and manufacturers have to implement solutions are only natural refrigerants: Carbon Dioxide (CO2), ammonia and Hydrocarbons.

CO2 is an odorless refrigerant, denser than air, has more favorable thermodynamic properties in low temperature applications than other natural refrigerants, has low viscosity, and high density. Its achievement is easy, it does not have any restriction of legislation (Treat it as a controlled substance), it is not Toxic, nor is it flammable.

Despite the wide advantages of CO2 as a refrigerant, in the region there is a lack of knowledge of the technology and its application, sometimes supported by lack of information, other times by paradigms that have been fostered by users and suppliers of technologies that have been in the market for a long time. Some of them will be described below:

- CO2 is only efficient in cold climates. It is true that CO2 as a refrigerant faces great challenges when its temperature is above 31.1 C since the substance cannot be condensed and is in the transcritical zone. But the implementation of the systems through various technologies has made it possible to improve or match the efficiencies of HFC systems so that they operate up to 45 C ambient. Here is the description of each system and its efficiency:

• For climates up to 27C a simple booster system can operate with equal or better efficiency than an HFC system. Application examples: Bogotá, Quito, southern Chile.

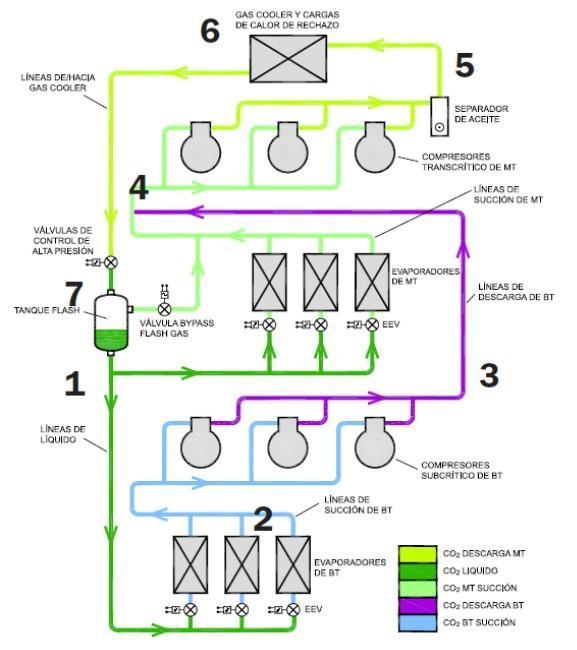

Figure 1.

• For climates up to 37 C a Booster system with parallel compressor can operate with equal or better efficiency than an HFC system. Application examples: Lima, Montevideo, Santiago de Chile, Mexico City.

• For climates up to 45C a Booster system with Parallel compressor and gas multi-ejector can operate with equal or better efficiency than an HFC system. Examples: Coastal areas of North South America, Central America, Caribbean.

In addition to the above, there are also implementations of gas sub coolers, or adiabatic condensers that, according to the required cooling power, and climatic behavior, can further extend the application of each technology in the temperature range.

Currently we have systems in environments that are in the 38 C environment in a 96 TR facility in Managua for a Distribution Center, and also facilities in desert zone in Trujillo Peru with 76 TR for a frozen room, and records temperatures of up to 30 C in Summer.

- CO2 handles high pressures and is only manageable in subcritical systems. It is true that the pressures that are handled in CO2 refrigeration systems are higher than the pressures used in systems with HFC, or ammonia. These values can even reach 1,400 psi when the ambient temperature exceeds 34 C, but they are pressure values found in many processes in industry. For example a hydraulic system, which is located under the operating chair of a forklift, has this pressure, and I have not found the first forklift user who argues danger in his work by having a hose under this pressure under his body, the user of the forklift is calm, because the fluid at that pressure is with appropriate materials and mounting technologies. The same happens with the CO2 cooling system. To better understand this situation, let's define the zones and their pressures:

• High pressure zone: includes the pipe path that goes from the discharge of the compression plant to the Cooler Gas or adiabatic condenser that is outside. This pipe is located outside the work areas and through the use of certified materials for these pressures: grade 6 carbon steel, stainless steel or Copper Type K65, a correct assembly is ensured.

• Intermediate pressure zone: corresponds to the liquid and gas pipes that go inside the installation. These pressures range from 125 psi to 700 psi, depending on the application temperature. The pipe that can be used is type K certified copper, and also stainless steel, and carbon steel.

In our facilities we have implemented the copper pipe for the entire liquid and suction area of the installation, and the discharge and return of the cooler gas has been stainless steel pipe.

- CO2 equipment is expensive. Since the first implementations of transcritical technology, more than 20,000 CO2 installations have been implemented, approximately 10% in industrial facilities. Equipment costs have fallen, and currently the value of the equipment is slightly higher than that of HFC but is much lower than that of recirculated ammonia, The most important thing is that not only the initial cost of the equipment must be taken into account but the TCO (Total Cost of Ownership) must be taken into account. For this analysis it is important to consider:

• Cost of mechanical installation: due to its high density, CO2 handles much smaller diameters than HFC and ammonia. While a linear meter of recirculated ammonia installation weighs 140 Kgrs, that of a CO2 installation weighs 20 Kgrs.

• Cost of civil works for machine rooms: the high density allows CO2 to use only Reciprocating Compressors in the equipment, which in turn allows the use of compressor racks or centralized systems. In an ammonia installation, due to the constructive characteristic, and the size of compressors, the interconnection of the systems comes in the field, and uses up to 10 times more area than that required for a CO2 system.

• Operating cost: CO2 systems bring the monitored operating variables: overheating of the system, evaporators, pressures and temperatures, are analyzed and the team automatically makes decisions. It is not necessary to have an operator.

• Maintenance Cost: CO2 systems require less maintenance than those of HFC and ammonia, since the constant measurement of variables allows us to make decisions against the variables to be controlled more precisely.

• Energy cost: having a centralized system with reciprocating compressors allows us to maintain the COP (Coefficient of Performance) of the system at partial loads. This does not happen with centralized systems, where even with frequency inverter systems and sliding valves the system is highly penalized in energy.

• The possibility of implementing systems that do not use water, or only use 20% of a traditional evaporative condensation system. This point is critical for many places in LATAM.

Currently in LATAM we have 5 systems dedicated to industrial application that use transcritical CO2 systems in Mexico, Nicaragua, Colombia and Peru, and their sizes range from 76 TR to 434 TR. This last system is applied for a distribution center comprising 16,777 m2 and more than 12,600 positions, a solution that would typically have been handled with recirculated ammonia but that the TCO analysis showed a significant saving in the implementation of transcritical CO2. In total, there are 1,126 TR that have prevented the environment from having the risk of receiving 8,042 tons of CO2.

CO2 becomes one of the most logical solutions for a large part of the region's industrial needs.

* Mauricio Baena. Mechanical Engineer from the Universidad Pontificia Bolivariana in the city of Medellín (Colombia), and Minor in Business Administration from Wichita State University in the United States. Professor at the Pontifical Bolivarian University and industrial University of Santander for the Academic Extension Area of the Faculty of Mechanical Engineering. 23 years of Experience in the Refrigeration sector: 7 years in the Maintenance area, and 13 years in the commercial and design area, and 4 years as a consultant: I currently work as Sales Manager for Hill Phoenix Industrial Division for South America developing the distribution channel for CO2 technology and Ultra low ammonia load, as well as support for the implementation of the different resources to provide installation and technical support services. In my professional career, within the design area, participation in the design and selection of refrigeration systems has been a constant, with more than 500 installations in 14 different sectors.

You can write to the mail: [email protected]