Energy, operational and installation savings are some of the reasons given in the article to take into account the use of this class of valves in air conditioning systems.

by Julio Londoño*

Energy, operational and installation savings are some of the reasons given in the article to take into account the use of this class of valves in air conditioning systems.

by Julio Londoño*

In the initial part of this article, the author highlights the benefits of independent pressure valves in decoupled or variable volume ice water air conditioning systems. In this second installment, we will see aspects such as the differential pressure of valves, balanced hydraulic systems, among others.

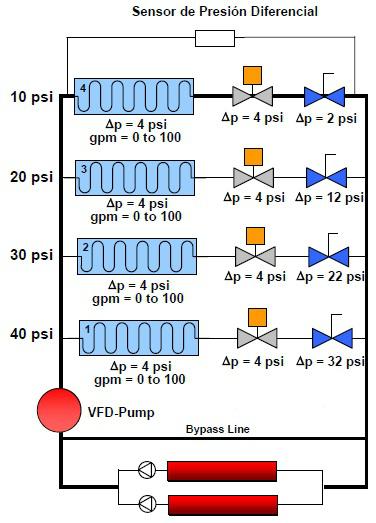

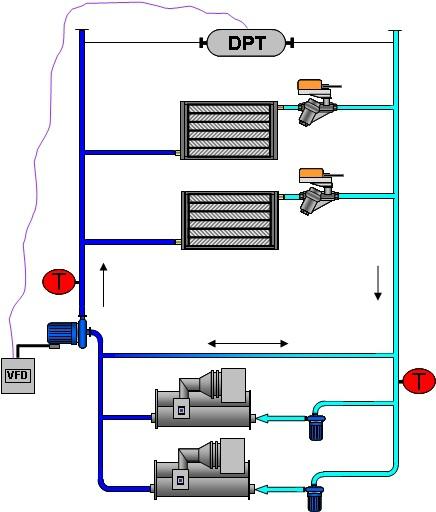

The differential pressure in the system is controlled by the DPT and the pump speed, if the valves close then the differential pressure increases and the VFD controls the pump at a lower speed to maintain the differential pressure set point of the system. This control, although very effective is not necessarily very efficient, because the valves are opening and closing continuously, this creates a dynamic where the pump only reacts to noticeable changes in the system and not to individual changes in each valve. This is most critical in high-rise buildings with many equipment with small valves such as hotels and office buildings.

Normally the differential pressure of a valve ranges from 5 to 30 psi, depending on how far it is from the pump and how well balanced the system is. The valves closest to the pump are subjected to higher pressure and are the most susceptible to overflow and hunting. The increase in flow in the valves, created by pressure changes in the system, generate temperature changes in the area.

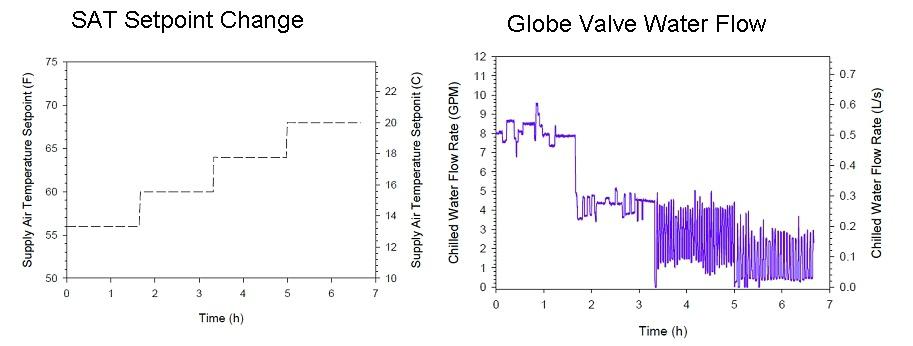

The controller reacts to these temperature changes and then adjusts the actuator to bring the zone temperature to its control point. These movements in the actuator are caused by the overflow and not by load changes in the conditioned area, as it should be.Chart-3

Operation of a pressure-dependent control valve at partial loads.

In this example, the differential pressure was maintained and the air temperature set point at the discharge was varied to simulate operation at partial loads. The behavior of the valve is very clear, at partial loads the control fluctuates because at this point the valve is oversized and operating under conditions different from those of design. (The full study can be downloaded from the following page: http://www.piccv.com/pdf/IOWA_PICCV_Testing_Analysis.pdf).

These rapid control fluctuations reduce actuator and valve life. In addition, each time the valve fluctuates above the required flow, there is an overflow in the coil. This overflow represents a waste of energy in over pumping and also causes you not to have a good heat exchange, making the water come out of the coil still cold, this is the biggest cause of low Delta T syndrome. Low Delta T syndrome is typical of systems that work at partial loads.

Hydraulic balancing

In this example, the differential pressure was maintained and the air temperature set point at the discharge was varied to simulate operation at partial loads. The behavior of the valve is very clear, at partial loads the control fluctuates because at this point the valve is oversized and operating under conditions different from those of design. (The full study can be downloaded from the following page: http://www.piccv.com/pdf/IOWA_PICCV_Testing_Analysis.pdf).

These rapid control fluctuations reduce actuator and valve life. In addition, each time the valve fluctuates above the required flow, there is an overflow in the coil. This overflow represents a waste of energy in over pumping and also causes you not to have a good heat exchange, making the water come out of the coil still cold, this is the biggest cause of low Delta T syndrome. Low Delta T syndrome is typical of systems that work at partial loads.

Hydraulic balancing

Just as important as valve selection is hydraulic balancing. The main purpose of balancing a system is to ensure that all coils have their design flow when the control valve is fully open. The procedure for balancing in principle is very simple. There are several techniques for hydraulic balancing, the following is a basic explanation to illustrate the process. For more details of balancing techniques you can consult specialized organizations such as NEEB (www.NEBB.org).

First, the critical valve is identified, this is the one that will first run out of water, it is usually the last of the branch, its balancing valve must be completely open. Second, all control valves are commanded from the central controller at 100%, at this time also all balancing valves must be open. Third, the flow in the coil of the critical valve is measured and the speed of the pump is increased until it reaches its nominal flow.

The other step is performed with all other balancing valves, in the next coil downstream of the critical valve the flow is measured and the balancing valve is closed until it reaches its nominal flow, simultaneously measuring the flow in the critical valve to ensure that it is maintained under conditions, for this the speed of the pump must be reduced.Chart-4

Balanced decoupled system

Balanced hydraulic system, note that the balancing valve of the last control valve is completely open. When all control valves are open there should be no flow in any direction on the bypass line

To obtain the expected results, several iterations of this process must be made, once finished and even with all the control valves open, the differential pressure value measured by the DPT is recorded and this will be the differential pressure adjustment point that controls the speed of the pump. At this time the flow of the primary circuit must be balanced in such a way that there is no flow in any direction on the bypass line.

Unfortunately this process is temporary and the system tends to become unbalanced over time. In addition, there is a danger that if for some reason one of the balancing valves closes the system loses the balance and the process must be repeated again. This process is so critical for energy saving that even in some buildings an independent company is hired to do only the balancing check. This is very characteristic of buildings that are seeking LEED certification. One of the most important steps of back-commissioning is to re-balance the system. In some buildings, savings in the energy consumption of the cooling plant of up to 40% have been achieved just by re-balancing the system.

For variable volume systems it is advisable to use automatic balancing valves, these adjust automatically and absorb pressure changes in the system and always guarantee a maximum flow in the coil. While these types of balancing valves offer a considerable improvement over manual ones. These only limit the flow at the peak and do not correct control valve fluctuations at partial loads. Therefore these do not help to correct low Delta T syndrome

Pressure Independent Valves

Balanced hydraulic system, note that the balancing valve of the last control valve is completely open. When all control valves are open there should be no flow in any direction on the bypass line

To obtain the expected results, several iterations of this process must be made, once finished and even with all the control valves open, the differential pressure value measured by the DPT is recorded and this will be the differential pressure adjustment point that controls the speed of the pump. At this time the flow of the primary circuit must be balanced in such a way that there is no flow in any direction on the bypass line.

Unfortunately this process is temporary and the system tends to become unbalanced over time. In addition, there is a danger that if for some reason one of the balancing valves closes the system loses the balance and the process must be repeated again. This process is so critical for energy saving that even in some buildings an independent company is hired to do only the balancing check. This is very characteristic of buildings that are seeking LEED certification. One of the most important steps of back-commissioning is to re-balance the system. In some buildings, savings in the energy consumption of the cooling plant of up to 40% have been achieved just by re-balancing the system.

For variable volume systems it is advisable to use automatic balancing valves, these adjust automatically and absorb pressure changes in the system and always guarantee a maximum flow in the coil. While these types of balancing valves offer a considerable improvement over manual ones. These only limit the flow at the peak and do not correct control valve fluctuations at partial loads. Therefore these do not help to correct low Delta T syndrome

Pressure Independent Valves

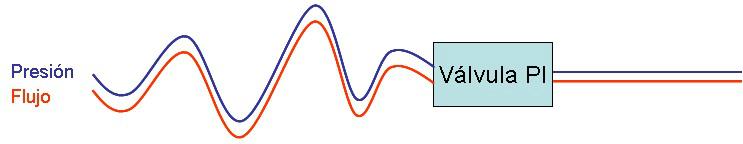

There is another alternative to controlling coils in systems that use variable water volume and is the use of Pressure Independent Valves (PI Valves).

Figure 1

Pressure-independent valves were specifically designed to work with variable volume systems and solve the problems that pressure-dependent valves present.

Because the pressure does not affect them, their selection is made very easy because there is no differential pressure component, the selection is made only with the required GPMs. So for our example simply select a PI valve of 100 GPM. The valves are factory ordered with the required GPMs.

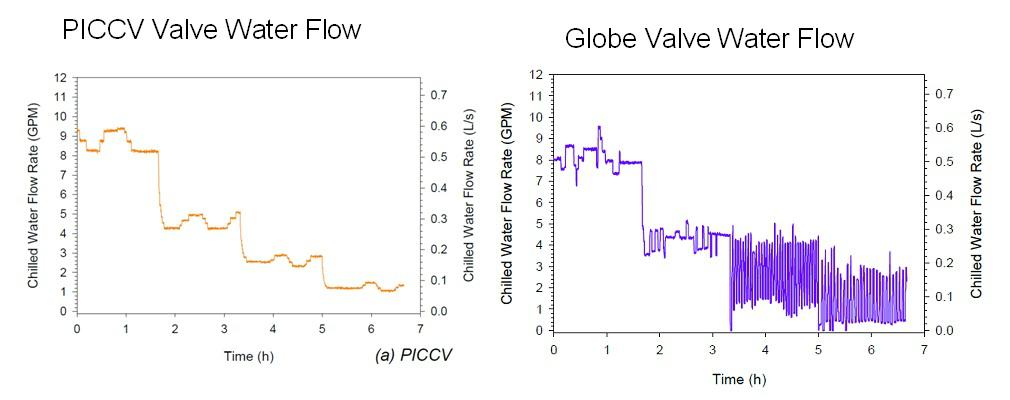

Where these types of valves really make a difference is controlling at partial loads. The following is a graph comparing the performance of a PI valve with a globe valve (Pressure Dependent).Chart-5

Behavior of PI valves at partial loads.

Due to this behavior, by eliminating overflow over the entire operating range of the valve the heat exchange in the coil is optimal thus maintaining the Delta T. Rapid fluctuations of the actuator are also eliminated, prolonging its service life and valve life.

Because PI valves are not affected by pressure, the system does not require balancing or balancing valves. Systems that use PI valves are also called self-balancing systems. The following graphic illustrates a decoupled system with PI valves.Chart-6

Self-balancing decoupled system using pressure independent valves.

Systems that use pressure independent valves do not require additional balancing valves.

The procedure for obtaining the pump speed control set point is simpler. First all PI valves are commanded 100% using the control system. The critical valve is identified and its pressure drop is measured. The pump speed is accelerated to 5 psi through the critical PI valve and the differential pressure value measured by the DPT is recorded, this will then be the control set point of the pump speed. The primary circuit is then balanced to ensure that there is no flow in any direction in the bypass.

While no balancing is required, the commissioning standard calls for a flow check to be done on each coil. PI valves normally require a minimum differential pressure of 5 psi to operate, the verification comes down to simply making sure each valve meets this requirement. There are two types of PI valves: Mechanical and Electronic.

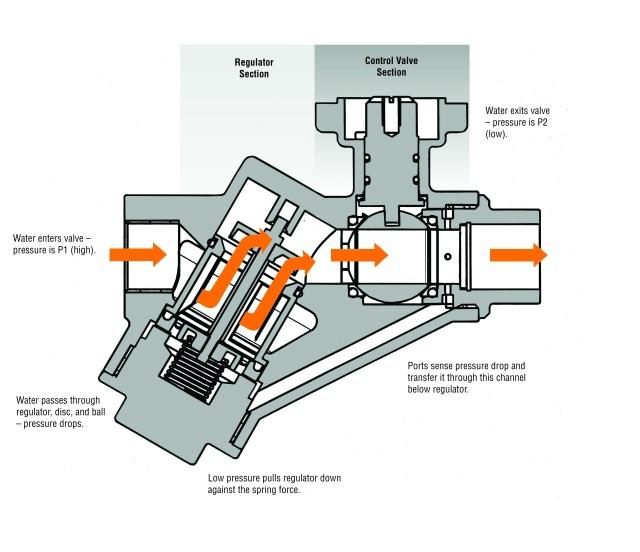

A mechanical PI valve has a differential pressure regulator built into the control valve. The flow rate passing through the valve is controlled by using a spring and diaphragm type pressure regulator that moves according to the pressure change above and below it. All pressure changes are absorbed by the pressure regulator, which allows the same differential pressure to be maintained along the control valve section; in this way it provides a constant flow.Chart-7

Systems that use pressure independent valves do not require additional balancing valves.

The procedure for obtaining the pump speed control set point is simpler. First all PI valves are commanded 100% using the control system. The critical valve is identified and its pressure drop is measured. The pump speed is accelerated to 5 psi through the critical PI valve and the differential pressure value measured by the DPT is recorded, this will then be the control set point of the pump speed. The primary circuit is then balanced to ensure that there is no flow in any direction in the bypass.

While no balancing is required, the commissioning standard calls for a flow check to be done on each coil. PI valves normally require a minimum differential pressure of 5 psi to operate, the verification comes down to simply making sure each valve meets this requirement. There are two types of PI valves: Mechanical and Electronic.

A mechanical PI valve has a differential pressure regulator built into the control valve. The flow rate passing through the valve is controlled by using a spring and diaphragm type pressure regulator that moves according to the pressure change above and below it. All pressure changes are absorbed by the pressure regulator, which allows the same differential pressure to be maintained along the control valve section; in this way it provides a constant flow.Chart-7

Operation of a Pressure Independent Valve

Electronic pressure independent valves combine a flow sensor with a two-way control valve. The actuator has an algorithm that modulates the control valve to maintain the exact flow according to the control signal of the zone temperature controller. So if there is an increase in flow due to a change in pressure, the actuator modulates the valve to keep the flow constant.

Due to its electronic nature, the flow signal can be read by the control system to make advanced control and energy saving routines, such as optimal control of the pumps and readjustment of the differential pressure point of the system based on the critical valve.

Conclusion

Electronic pressure independent valves combine a flow sensor with a two-way control valve. The actuator has an algorithm that modulates the control valve to maintain the exact flow according to the control signal of the zone temperature controller. So if there is an increase in flow due to a change in pressure, the actuator modulates the valve to keep the flow constant.

Due to its electronic nature, the flow signal can be read by the control system to make advanced control and energy saving routines, such as optimal control of the pumps and readjustment of the differential pressure point of the system based on the critical valve.

Conclusion

Air conditioning systems are constantly evolving, and these changes are motivated by the need to save energy and document the operation of buildings. PI valves are the next step in the evolution of ice water and hot water systems for air conditioning. Its greatest benefit is the optimization in the use of energy in the ice water plant by eliminating overflow and maintaining the Delta T. They also offer savings in installation and operation.

*Julio Londoño is the Product Manager of Belimo ([email protected])