International. A 1917 discovery becomes viable for the future. A team of researchers from the Fraunhofer Institute for Physical Measurement Techniques IPM is developing efficient magnetocaloric cooling systems that work without harmful refrigerants. The researchers hope to reach 50 percent of the maximum level of efficiency with their process. Comparable existing magnetocaloric systems reach only about 30 percent.

International. A 1917 discovery becomes viable for the future. A team of researchers from the Fraunhofer Institute for Physical Measurement Techniques IPM is developing efficient magnetocaloric cooling systems that work without harmful refrigerants. The researchers hope to reach 50 percent of the maximum level of efficiency with their process. Comparable existing magnetocaloric systems reach only about 30 percent.

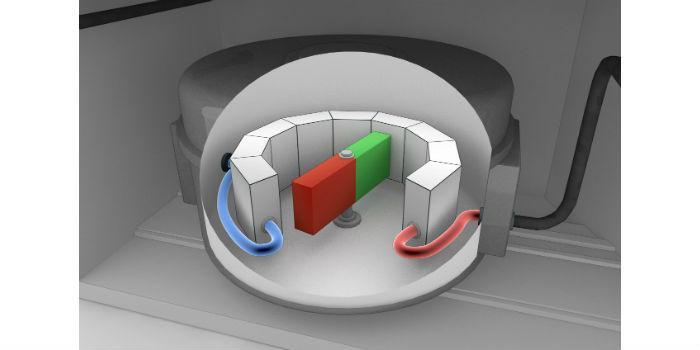

Many research groups around the world are working on refrigerators, industrial cooling systems, and air conditioners that pump heat using magnetocaloric materials (see image). The heating and cooling cycle generated by magnetization is excellent for cooling. Physicist Dr. Kilian Bartholomé and his team at the Fraunhofer IPM in Freiburg, Germany, are using this technology to develop an extremely efficient thermal conductivity concept that eliminates the need for environmentally harmful refrigerants.

Environmentally friendly lanthanum-iron-silicon alloy as a magnetocaloric material

A magnetocaloric cooling system does not require harmful refrigerants of any kind. The researchers are using an eco-friendly lanthanum-iron-silicon alloy as a magnetocaloric material, which heats up when a magnetic field is applied and cools when the field is removed. Kilian Bartholomé and his team have developed and patented a special procedure for transferring the heat produced.

Bartholomé's cooling system uses latent heat, that is, the energy required by a liquid to become vapor. "Since water absorbs a lot of energy when it changes from a liquid state to a gaseous state, we use the evaporation process to transfer heat," says the physicist. "This is a highly efficient means of transferring thermal energy."

Deciding to use the evaporation process for heat transport, Kilian Bartholomé and his colleague Jan König were inspired by heat pipes used, for example, as pipe collectors in solar energy systems and for cooling computers. A heat pipe is an evacuated vessel, where a small amount of fluid has been enclosed. If one side of the pipe is heated, the fluid evaporates on this heated side and condenses again on the cold side. Very high heat transmission rates are achieved in the process.

However, the magnetocaloric heat pipe that develops at Fraunhofer IPM is significantly more complex. It consists of many small chambers containing the magnetocaloric material. The alloy has a finely porous structure so that it can be optimally penetrated by water vapor. The method for producing the porous alloy is the work of Dr. Sandra Wieland and Dr. Martin Dressler at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM.

New world record for magnetocaloric cooling systems

To further increase efficiency, Bartholomé arranges the heat pipe segments in a circular pattern and places a rotating magnet in the middle. The demonstrator is expected to generate 300 watts of power by the time it ends at the end of the year. For comparison: the compressor in a household refrigerator produces 50 to 100 watts of power. The current system already operates at a very high frequency.

Researchers in Freiburg plan to use the demonstrator to break a world record for magnetocaloric cooling systems regarding system frequency. The long-term goal is to reach 50 percent of the theoretical level of maximum efficiency. Comparable existing systems reach about 30 percent.

Industry players are already expressing great interest in research, for example Philipp Kirsch GmbH, which manufactures special refrigerators for medical laboratories, pharmacies and hospitals. The former German company is working together with Fraunhofer IPM on a project sponsored by Germany's Federal Ministry of Economics and Technology (BMWi). "We want to put a minus 86-degree unit on the market based on magnetocalorics," says CEO Jochen Kopitzke. "Magnetocaloric has a very large disruptive potential and might be able to replace compressor-based cooling in the mean timeframe. We see here a clearly developing market that we can penetrate."

Source: Fraunhofer.

Leave your comment