The use of complete software, the updating of modern systems and the knowledge of new technologies are important aspects in the proper execution of a maintenance plan.

The use of complete software, the updating of modern systems and the knowledge of new technologies are important aspects in the proper execution of a maintenance plan.

by Eng. Felipe Airoldi Accorsi*

Good refrigeration practices bring benefits to the environment and quality to the services provided, providing longer service life and better energy efficiency of refrigeration and air conditioning systems. These actions, applied to industrial and commercial refrigeration equipment, are able to keep the system operating at full capacity, with minimal downtime and reduced operating costs. For this, a series of actions must be implemented, carried out from the initial stage of the project, through the installation and execution of a good maintenance plan.

The adoption of monitoring software for the monitoring and control of refrigeration systems is a modern and convenient practice, increasingly used in industries and businesses due to the benefits derived. These systems facilitate operation, speed up the identification of problems, reduce downtime, allow better maintenance planning and programming to reduce energy consumption. Through electronic controllers connected to these management software, it is possible for those responsible to remotely control the plant.

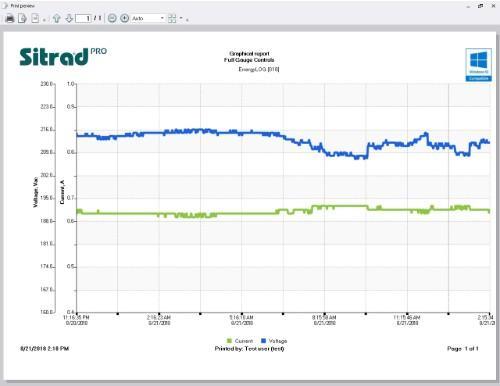

The main functions of these softwares are real-time accessibility to monitoring and sending commands on setpoints, temperatures, pressures, electrical voltage, equipment failures or other previously established parameters. In addition, we can highlight the communication and automation facilities, such as the possibility of receiving alerts by cell phone or email, according to the conditions of the system, and of programming the thaw of the evaporators and economic setpoints.

The monitoring software, in addition to promoting agility in the operation, result in financial benefits, since they allow to identify failures and visualize the opening time of the doors easily, in addition to programming setpoint changes in periods of low demand. The Sitrad, developed by Full Gauge Controls, is offered at no licensing cost (can be downloaded from www.sitrad.com/es) or technical support. The tool, which works exclusively with controllers of the brand, allows remote and real-time command of the refrigeration plant or commercial installation, through communication with the electronic controllers of the equipment. To access the information it is enough to have at your disposal a device (tablet, computer or cell phone) connected to the Internet.

Maintenance plan

Another good practice to keep cooling systems at full capacity and with low energy consumption is the development and execution of a good maintenance plan. This programme should include regular inspections of the main components of the refrigeration system and provide for cleaning and preventive changes of essential devices. A widely adopted measure in industries is to appoint a technician responsible for the execution of periodic inspections. These good maintenance practices, in addition to guaranteeing the verification of the most important components of the equipment, create affinity of the technician with the system and enable a better agility and organization of preventive stops.

The verification stages of the maintenance plan should be elaborated from a particular system study.

Generally, these include the inspection of the existence of corrosion, leaks, the state of conservation of thermal insulators, the measurement of the pressure differential of the filters, the verification of operating pressures and the operability of the safety devices. The execution of preventive maintenance must include the changes and corrections found in the inspection stages, in addition to other particularities of the system, such as the lubrication of the fan bearings, the oil change of the compressors and the cleaning of the heat exchangers.

Keeping up with new technologies is a good practice that contributes to the evolution of the maintenance process, allowing the adoption of techniques for the prevention of failures. Currently, there are equipment that are simple to operate and perform the complex activity of monitoring and preventing damage or malfunction of the cooling system due to the poor quality of electrical power.

Using technology to your advantage is essential to ensure the safety and functionality of refrigeration systems, reduce unscheduled maintenance downtime, and the cost of repairs caused by electrical damage. The PhaseLog E plus, from Full Gauge Controls, analyzes the quality of electrical power and allows for reporting. This instrument is capable of measuring, storing data and protecting the system from variations in voltage, lack of phase, angular and modular asymmetry, and recognize inversion in the connection of the phase sequence.

The modern vision of maintenance also aims to adopt more efficient equipment, seeking a reduction in energy consumption. The measure is beneficial for the environment and generates savings. Currently, thermostatic valves (TEV), which are 100% mechanical, are being replaced by electronic expansion valves (EEV). This trend of technology migration occurs by controlling the degree of overheating of the EEVs by being more precise and modulation, faster. These characteristics make it possible to reduce energy consumption and result in economic benefits, which justify their acquisition cost.

Electronic expansion valves use a pressure transducer and a temperature sensor, positioned at the evaporator outlet, both connected to an electronic controller. This modulates the actuator, usually a step motor, and converts the value of the pressure and temperature reading to determine overheating and regulate the opening of the valve hole. To ensure proper operation, it is important to observe the insulation of the temperature sensor to maintain the reading more faithful to the temperature of the fluid and the proper positioning of the pressure transducer, in order to avoid damage in case of a water hammer.

Water hammer is a pressure spike caused by a sudden change in the velocity of the coolant fluid in the pipe. These disturbances can happen in refrigeration systems due to valve closure or sudden compressor shutdown. Pressure transducers may be the instruments most affected by this phenomenon, as there is a possibility that their limit will be exceeded and they will be deregulated or damaged. A good practice to try to minimize the impact of the shock wave on the pressure transducers is to position them inclined in the pipe (see figure).

Figure 1.

This set of modern actions adds new technologies to the cooling system. It is vital that the inclusion of contemporary practices is established in the management of the preventive maintenance plan, control, accessibility and registration of technical data of the plant, to guarantee the proper functioning of the installation and, in addition, generate savings.

* This article was written by Eng. Felipe Airoldi Accorsi, technical product consultant for Foreign Trade at Full Gauge Controls.