Second part of this analysis on the available technological alternatives that directly influence to achieve a lower environmental impact on HVAC/R.

Second part of this analysis on the available technological alternatives that directly influence to achieve a lower environmental impact on HVAC/R.

by Eng. Carlos C. Obella*

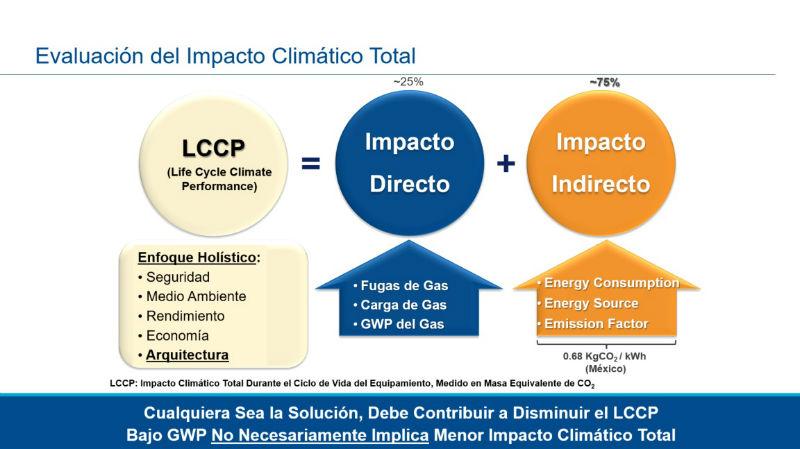

Total Climate Impact Assessment: The total climate impact over the life cycle of equipment (LCCP) is measured in CO2 equivalent mass. This concept combines the type of refrigerant adopted with the architecture of the system in which it is applied, in addition to the operating conditions, and even the geographical location of the system to be considered. Its total value arises from the sum of the direct impact plus the indirect one (Fig.7)

Fig. 7

The direct impact depends on the type of gas and its GWP value, in addition to the gas load of the system and the percentage of leaks measured throughout the life cycle of the equipment. The indirect impact depends on the energy consumed by the system measured in KW and the mass of CO2 emitted for the generation of each KW that the system consumes throughout its life cycle. The latter depends on the source or resource of power generation that is applied (Emission Factor).

The goal in finding the best solution is to decrease the value of LCCP as much as possible. Once again this raises commitments in terms of safety, environment, performance and economy that must be evaluated and assumed, with a holistic approach.

For example, in a commercial self-contained refrigeration system with very low gas load and low risk of leakage, the indirect impact in terms of energy efficiency will have a much greater weight than the direct impact on the decrease in LCCP. The best refrigerant option can be one that allows obtaining the best energy efficiency, without losing sight of the end of the useful life of these systems, and the potential direct impact generated at the time of having this equipment. The same concept is applicable to a residential air conditioning or heat pump system, for example.

On the other hand, if we consider a centralized commercial refrigeration system, which works with direct expansion, similar to those commonly installed in large commercial premises such as supermarkets; with long pipe lines, extending from the engine room to remote evaporators; with huge gas loads, on the order of hundreds of kilos; with high risk and annual percentage of leaks; here the direct impact will have a greater weight. Employing a low-GWP refrigerant will be key, if significant changes are not made to the system architecture. Here too the final disposal will be very important, in terms of gas recovery and its potential reuse for service.

In general, the indirect impact is usually greater than the direct one, mainly in those countries where the CO2 Emission Factor emitted by each KW generated is high.

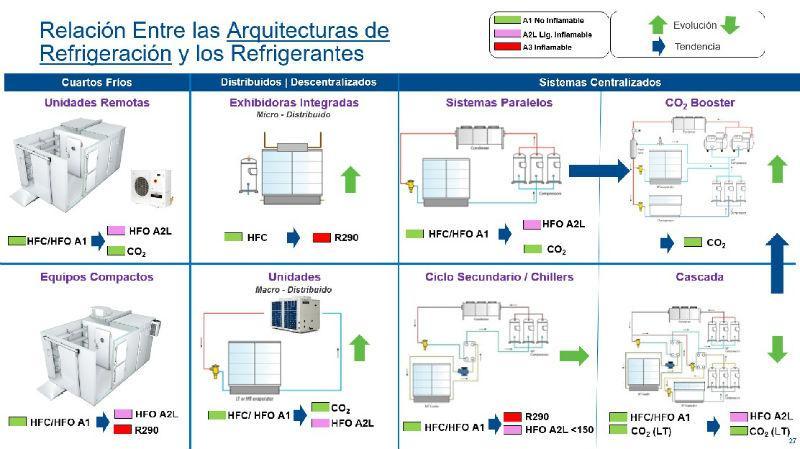

Relationship between refrigeration system architectures and refrigerants: trends in terms of sustainability that seek to reduce refrigerant gas loads and leaks have driven a wide variety of options in refrigeration system architectures that must be understood in depth, in order to comparatively analyze their advantages and disadvantages, their potential benefits, its effectiveness and energy efficiency, its installation, operation, maintenance and final disposal costs, in addition to its environmental impact, among other important aspects to consider and weigh (Fig. 8).

Fig. 8

There are multiple variants: decentralized systems that apply condensing units for outdoor, indoor, or compact; micro-distributed systems that apply water condensation circuits; large centralized systems of direct expansion; secondary cycle systems; pure and hybrid cascade systems; two-stage systems (called "Booster"). All these variants, believe it or not, are present and active today in Latin America. And in certain cases, more than one type of system architecture can be present in the same commercial premises, in high, medium or low temperature applications, in combination with air conditioning.

The variety of refrigerants that are applied for each configuration adds even more complexity, if one considers the evolution of current, intermediate and future options, with less environmental impact.

Trends in commercial refrigeration system architectures by format size: Figure 9 shows us certain trends in the adoption of architectures for commercial refrigeration systems by type and size of format.

Fig. 9

- Larger surfaces tend to apply 100% natural solutions with CO2, in systems of the "Booster" type or two external stages.

- Medium formats typically opt for hybrid cascades, secondary cycle systems, micro-distributed systems, and decentralized units. Here the options and types of refrigerant are expanded.

- Smaller formats apply decentralized systems, with condensing units of exterior, interior, or compact application, in combination with self-contained systems or refrigerated displays.

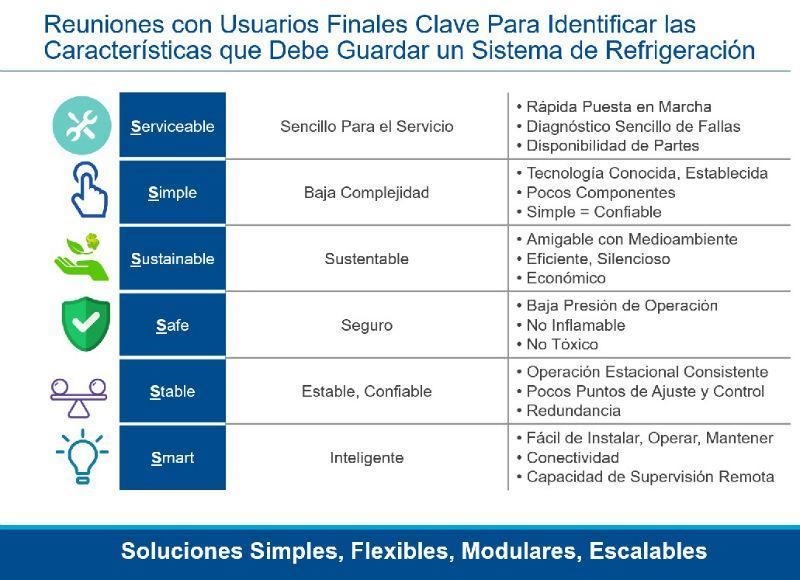

Features that a refrigeration system must keep according to some key end users: Most end users of commercial refrigeration systems in the food retail industry in the U.S. agree to list the following features (fig. 10): simple, low complexity, safe, sustainable, stable, intelligent.

Fig. 10

As can be seen in the table, the word that defines each of these characteristics begins with the letter "S" in the English language. Hence, this trend is called "Six Eses" (6S's).

This same analysis is perfectly valid for Latin America, if we consider that the trends that have been occupying us in this article (sustainability, efficiency and connectivity) tend to add complexity to technological solutions, and in many cases compromise safety, whether they apply refrigerants with a certain level of flammability or operate at high pressures.

Digitalization, connectivity, electronic integration

The current trend is to control the different combinations between systems and refrigerants using electronic devices. These devices receive input signals from sensors and transducers, which are processed by complex control algorithms to generate output signals, both analog and digital. The basic control parameters can be temperature and pressure, to which the flow of air, water or intermediate fluid can be added; or electrical parameters such as consumption in Amper and voltage, which are combined by other algorithms to measure and control energy consumption, for example. Other types of sensors allow to detect the presence of gases for the purpose of detecting leaks. And there's much, much more to this.

Fig. 11

The interaction of electronic devices with the user can be local (visual, sound or a combination of both) or remote, in real time, or through histories or records visible through monitoring systems that allow, among other things, to alert, diagnose and actively protect the integrity of the system, and thus ensure the conservation and level of quality of the fresh products stored or the comfort of a conditioned premises.

In turn, each electronic device can fulfill its function individually or it can be integrated and communicated with other devices through various open or closed communication protocols. The ability to integrate can expand through the Internet of Things (IoT) and involve both refrigeration and air conditioning systems for comfort, ventilation, lighting, and other services.

The generation and recording of data from different key electronic components can be transformed into valuable information through executive processors that apply advanced software, with the purpose of helping the user make better operational decisions. Finally, the totality of the information can remain accessible and be stored unlimitedly on servers interconnected through "The Cloud".

Figure 11 shows a practical example that combines the concepts stated, with the purpose of managing operating costs (energy, maintenance, loss of merchandise) in a supermarket.

Training is indispensable

Innovative companies that offer the technologies described above see the need to train their own technical staff, their customers and end users in the fundamentals of various technical disciplines such as thermodynamics, chemistry, control systems, electronics and computer science, among others.

This training must be practical and very effective, using educational means available online, videos, advanced simulators, virtual reality, among other tools, to the point of transforming this training into a true educational experience. This is the function of the so-called Learning Centers (Fig. 12).

Fig. 12

Emerson has two such advanced centers, strategically located in Brazil and Mexico. Each Learning Center is able to simulate a wide and varied number of different refrigeration and air conditioning applications for educational purposes, offering flexible training programs, which can be adapted to specific needs.

These true sources of knowledge are also open to educational entities, such as universities, and vocational training schools, with the purpose of developing technical skills in various areas of our industry.

The doors of these Learning Centers are open to professional associations that wish to train and certify their affiliates in various disciplines, and also for government entities that seek to train professionals in good practices, aimed at complying with standards and regulations, environmental and energy efficiency, both current and future.

In short, each Emerson Learning Center is an ideal place to live a true educational experience, expand our knowledge and expand thinking, as well as being a source of innovative ideas, generated in a collaborative environment, to face present and future technological challenges.

Conclusions

- Sustainability, energy efficiency, and connectivity are key global trends.

- The application of refrigerants with a lower environmental impact implies opting for options with a certain degree of flammability, or that operate at high pressures.

- Compliance with regulations, norms, standards, building and safety codes become more important.

- Indirect impact becomes more important in the assessment of total environmental impact, versus direct impact.

- End users are looking for simple, flexible, modular, scalable solutions.

- Education and training are critical to keeping up with the changes in our industry.

* Eng. Carlos C. Obella. VP of Engineering Services and Product Management

Emerson Commercial & Residential Solutions Latin America. [email protected]

References

1. (Heschong) Heschong Mahone Group and CTG Energetics. 2008. White paper on approaches to reducing leakage and improving the performance of supermarket refrigeration systems, submitted to Southern California Edison Co. for California Title 24.

2. Proposed Waxman-Markey bill signed by the House and pending in Senate.

3. Van Baxter, Oak Ridge National Lab, IEA Annex 26 report, Advanced Supermarket Refrigeration Systems, April 2003.

4. Steve Brown, Samuel Yana Motta, Piotr Domanski, National Institute of Standards and Technology, Comparative analysis of an automotive air conditioning system operating with CO2 and R134a, International Journal of Refrigeration, Jan 2001.

5. Mark Spatz and Barbara Minor, Next generation low GWP refrigerant HFO-1234yf, Honeywell and Dupont joint presentation, Jan 23, 2008.

6. The Air Conditioning, Heating and Refrigeration Institute (AHRI) Alternative

Refrigerants Evaluation Program, CD Volumes I & II reports (1992-1997), report 196

7. 2010 International Symposium on Next-gen AC&R technology, Japan, Feb. 17, 2010:

a. Mark Spatz, Honeywell International, Low global warming alternative refrigerants for stationary AC&R applications.

b. Hayato Horie, University of Tokyo, Study on cycle property and LCCP evaluation of heat pump using HFO-1234yf, HFC-32, and HFC-410A as refrigerant.

c. Thomas Leck, Dupont Fluorochemicals, Development and evaluation of high performance low GWP refrigerants for AC and Refrigeration.

d. W. Rached, J.Komornicki, C.Maldeme, Arkema, Safe and environment friendly refrigeration and refrigerants.

e. Hideki Hara, Masao Oono, Ikuhiro Iwata, Daikin Industries LTD., Experimental study of low GWP refrigerants for room air conditioners.

f. Takashi Okazaki, Hideaki Maeyama, Makoto Saito, Takashi Yamamoto, Mitsubishi Electric Corporation, Performance and reliability evaluation of a room air conditioner with low GWP refrigerants.

g. Akira Fujitaka, Tsutomu Shimizu, Shigehiro Sato, Yoshikazu Kawabe, Panasonic Corporation, Application of low global warming potential refrigerants for room air conditioners.

8. EPA, pending Significant New Alternatives program (SNAP) investigation for HFO1234yf, Federal Register notice, Vol 74, no. 200, Monday Oct. 19, 2009 proposed rule

9. AHRI/ACEEE/Alliance to Save Energy, proposed regional standards for inclusion in Energy Bill, Oct. 2009.

10. Osami Kataoka, The challenges of the Japan Refrigeration and Air Conditioning Industry Association (JRAIA) to mitigate GHG(HFCs), July 14, 2009, Bruxells conference.

11. Steve Brown, HFOs new low global warming potential refrigerants, ASHRAE Journal, Aug. 2009

12. Pande M., Y.H. Hwang, J. Judge, R. Radermacher. An experimental evaluation of flammable and non-flammable high pressure HFC replacements for R22, 1996 Purdue

Compressor Conference.

13. Piotr Domanski, David Yashar, Comparable performance evaluation of HC and HFC refrigerants in an optimized system, National Institute of Technology and Standards, 7th

Gustav Lorentzen Conference on natural working fluids, Trondheim, Norway, May 28-31, 2006

14. Next Generation Refrigerants: Standards and Climate Policy Implications of Engineering Constraints, by Hung Pham, Emerson Climate Technologies, Harvey Sachs, American Council for an Energy-Efficient Economy

Leave your comment