A consultancy carried out for an evaporative cooling tempering system for the packaging area, located in the aisle, and recommendations for its assembly.

A consultancy carried out for an evaporative cooling tempering system for the packaging area, located in the aisle, and recommendations for its assembly.

by Camilo Botero*

Below are the concepts on compliance with the design parameters for an indirect evaporative cooling tempering system for the packaging area in a snack plant, located in an area with a humid tropical climate, with emphasis on the requests received in visits to the plant site, for repeated complaints on the part of the Human Resources office due to the thermal stress of the operators' staff; bearing in mind the environmental conditions of temperature, relative humidity, specific humidity and the conditions of thermal stress defined by the government entity in charge of these issues, at different points of the packaging area.

A system with indirect evaporative cooling was designed to achieve the best tempering, under the extreme conditions of ambient temperature, relative humidity and solar radiation. Notice that I have coined the word tempering in order not to generate expectations beyond what the indirect evaporative cooling system can achieve, under extreme conditions. Words such as "air conditioning" or "conditioning" should be avoided in this type of project and be very clear with the "best" conditions, which can be achieved.

Introduction

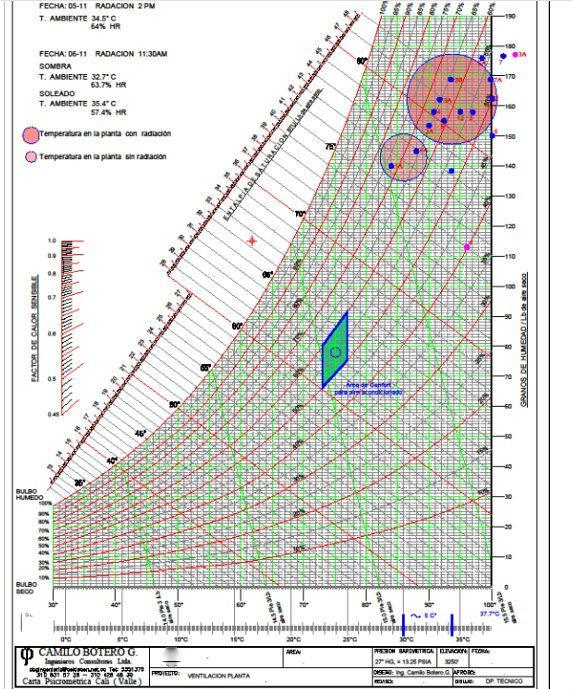

Through this article, concepts requested for the design of the indirect evaporative cooling tempering system for the snaks packaging area are presented, object of this study. The investment of the assembly of equipment and installation of its corresponding ducts must be taken into account, whose design and distribution will be made by the method of static regain (recovery of static pressure), with its electrical and water connection, with the pressure required by the equipment so that such indirect evaporative cooling can effectively occur, up to the lowest possible temperature for extreme conditions of temperature and relative humidity outside. (See psychrometry).

Figure 1.

Through a progressive design process, the respective recommendations and suggestions were given, to improve the tempering of the air on the people in the packaging area which is supplied by the handling unit that was installed, with a flow of the order of 10,000 CFM (Currently there are already 3 similar handling units)

It is necessary to take into account the approximations given in the initial psychrometric study, and to specify that the indirect evaporative cooling will not reach comfort conditions, but it will give a sensation of apparent temperature with much less thermal stress in relation to that which was had in the plant on the people in the aforementioned work area, in addition to the fact that the water treatment was carried out to carry out the respective cooling; this is a definite factor for the proper functioning of the system.

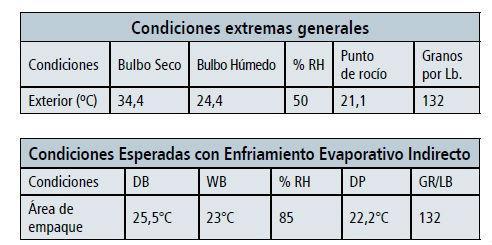

Table 1.

The purpose of ASHRAE Standard 55 is to specify the combinations of indoor thermal environmental factors and personal factors that will produce acceptable thermal conditions for most occupants within the space. The environmental factors considered are temperature, thermal radiation, humidity and air velocity; personal factors are activity and clothing. It is intended that all the criteria of the standard are applied together, because comfort in the environment is complex and responds to the interaction of all the factors that are addressed.

The definition of thermal comfort according to standard 55 of the American Society of Heating, Cooling and Air Conditioning Engineers (ASHRAE) is:

"That condition of the mind which expresses satisfaction with the environment and is evaluated subjectively."

To this last concept, that is to say that the sensation of thermal comfort is subjective is to which the design efforts for this application in the packaging area of a snack plant were directed. This definition is a bit ethereal, since the terms "condition of the mind" and "satisfaction" are ambiguous, but clearly emphasize that the perception of thermal well-being is a cognitive process, which involves a wide variety of parameters influenced by physical processes, physiological, psychological and other

An indirect evaporative cooling equipment, in order to reach its minimum temperature at the point of air supply, must have the water with the proper pressure in the supply line which would produce a lower apparent temperature in the operators. (See psychrometry – Graph 1).

The initial selection of linear diffusers that were initially located in the supply ducts should be single-slotted so that they produce a higher speed and thus improve the apparent temperature sensation, and should be carefully selected, hopefully with the help of a flow simulator in the discharge.

The linear diffusers must be directly above the packaging operators in order to achieve the use of the indirect evaporative cooling system, in the perception of better apparent temperature and relative humidity generating well-being of the workers.

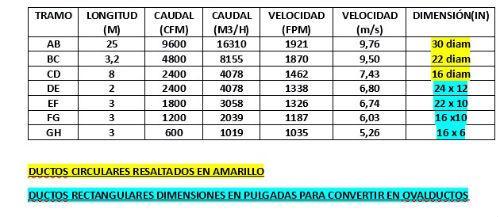

The supply ducts of the oval type to decrease their height and place them under a mezzanine, were designed by the static regain method based on Bernoulli's equation. When I did my design course at Carrier Syracuse NY, we had a ductulator that I still have, which allowed calculations to be done with this method. The purpose is to maintain the same static pressure within the pipeline so that at the supply points the output flow is the same throughout the pipeline and so all people benefit equally from the tempering system.

Searching the internet, he found a free software for designing ducts by the static pressure gain method; an example of the results is shown below, combining SI and IP units.

Then with the technical support of a local duct manufacturer, conversions were made to the dimensions of the oval ducts.

Table 2.

The conditions, when the measurements were made, had the oval ducts selected by the static gain method and with supply by round holes of 2" in diameter, calculated with a discharge speed of 700 feet / min and with speeds on the operators of approximately 400 feet / min, in the packing area. Finally, better results were achieved with the supply by the round holes, than with the linear diffusers.

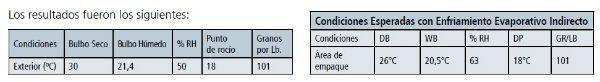

The results were as follows:

Table 3

Although these conditions are far from the thermal comfort zone, as defined by the ASHRAE standard 55 and the RITE version for Colombia, the comments of the operators in their workplace, with the latest design and assembly once corrected problems of duct dimensions, more convenient number of holes per linear meter, their height above the operators and with a self-balanced flow rate due to static pressure gains; the flow, pressure and treatment of evaporating water in the evaporative cooling air handling unit; the operators expressed their satisfaction by saying:

"Leave it there engineer... it's perfect!!!! "

This corroborates that thermal comfort is subjective, circumstantial and relative.

* Camilo Botero is the current Secretary of the Federation of Ibero-American Associations of Air Conditioning and Refrigeration - FAIAR; he was president of ACAIRE and is president of Camilo Botero Ingenieros Consultores Ltda. He has worked as a teacher in several Colombian universities, guilds and currently in ACAIRE in diploma courses of air conditioning projects, energy efficiency in air conditioning and refrigeration, cogeneration and trigeneration, applied psychometrics, thermodynamics, fluid mechanics, heat transfer and turbomachinery. ([email protected]).