First part of this special on the most common errors in design, installation, operation and maintenance in refrigeration systems in supermarkets and supermarkets.

First part of this special on the most common errors in design, installation, operation and maintenance in refrigeration systems in supermarkets and supermarkets.

by Giovanni Barletta*

Mechanical refrigeration systems are a determining factor in the conservation of the cold chain in storage, distribution and marketing of retail products, which is why their proper use is essential in each installation of this type of establishment.

The "food cold" process includes all those systems and subsystems involved in the conservation of the cold chain either in supermarkets, supermarkets and even convenience stores of refrigerated or frozen products for retail sale; from the refrigeration system, to the exhibition in the sales area through the conservation chambers and the process areas. Regularly the display refrigerators and cold rooms are connected to a cold center (Rack). This refrigeration plant consists of a group of compressors that discharge in parallel to a common condenser through a high-pressure "manifold" and dissipate all the heat to a condenser located outdoors that is regularly of the air condensed type.

This refrigerant already in the liquid phase and after being stored in a tank either horizontally or vertically is distributed in a network of copper pipes throughout the business until each evaporator or final display.

Normally there are only two temperatures in the cold plant Medium temperature (MT) and low temperature, where the first is typically evaporating between 12 and 16 F and Low Temperature (LT) between -23 and -25 F.

The problem of these facilities is that they are highly demanding both in their reliability and availability and in the stability of the temperature conditions and humidity of refrigerated furniture, because it compromises the quality of the product either exhibited or stored and that in many cases is very sensitive to changes in these variables and if they are not properly preserved ends up affecting not only the commercial management of the business and the prestige of it, if not putting at risk the life and health of people amen of the high maintenance costs associated with each intervention.

The many years of work within the commercial sector either as responsible for maintenance, or its operation or having intervened in its designs allows me to conceptualize about them and classify this problem under several parts that are sometimes interrelated with each other:

1. Considerations from the design.

2. Limitations and challenges in the Installation processes.

3. Inconveniences generated from the operation.

to. From the cold plant.

b. From the exhibitor (User).

4. Maintenance challenges.

Design

Design is the genesis of everything, from here begin the speculations about which is the most appropriate architecture and in this each continent (Europe and North America) has its preferences, as well as each manufacturer its own. From all this analysis, the advantages between simpler architectures at the expense of operation with conventional efficiency or more complex networks and controls in search of gaining some points in efficiency and security are debated. There is no universal criterion as to which is ideal; the user and client must understand the pros and cons of each and where to focus their investment. Some criteria go through aesthetic issues at the point of sale, the ease or complexity to do the maintenance, either from a central or from the end points, as well as in the will or not to do monitoring and centralized records.

- System architecture: On the one hand there are the centralized multi-circuit systems where all the mechanical and electronic elements and control are located directly in the rack, including liquid line and defrost solenoid valves (If applicable), evaporation pressure regulating valves, temperature control and recording all installed, monitored and operated from the cold center; on the other hand, we have the distributed systems or loop type where all the aforementioned elements are scattered around the store and the controls are handled locally in the display or cold room as the case may be.

- Defrost: Another important design factor to consider is the fact of thawing by electrical resistance or using the heat of the refrigerant as an energy source for defrosting (Hot Gas or Cool gas) poses a dilemma between what is more favorable, the simplicity of the design of the pipe networks in the store that thaws with the resistors at the expense of the additional electrical power needed causing a higher energy consumption or the gain in defrosting efficiency that is obtained by thawing with hot refrigerant either taken in the discharge line (hot gas) or already cooled in the condenser at the height of the liquid receiver (Cool gas) and taking advantage of the latent heat of the phase change making the defrost cycles shorter and aiming at the efficiency of the system, but with a higher cost in the installation. More complexity in valve systems, controls and final fine tuning.

- Pipe sizing: Additionally, special care must be taken in the correct sizing of the liquid supply pipe networks to avoid flashing the refrigerant at the inlet of the expansion valve and especially those of suction gases where the speeds are critical for an appropriate return of oil.

The lack of design or a bad development of this, will be reflected well in excessive speeds with penalty in the pressure drop or at the opposite end where large diameters prevent oil returns.

There are two variables that determine the good sizing of a pipe and that become opposite to each other: the speed that is high enough to guarantee an adequate return of oil but that is not so high that it penalizes excessively the pressure drop.

It is regularly measured associated with a pressure drop equivalent to a temperature change in the line. Good practice recommends the following conditions:

- Liquid Line, Speed 300 fpm, Pressure drop 1ºF

- Horizontal suction lines, Speed 700 fpm, Pressure drop 2ºF

- Vertical ascending suction lines, Speed 1500 fpm, Pressure drop 2ºF

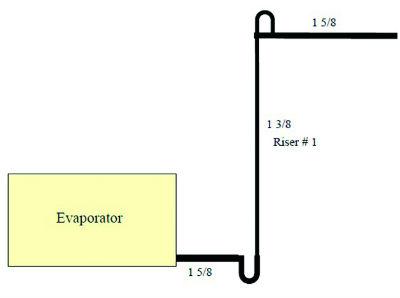

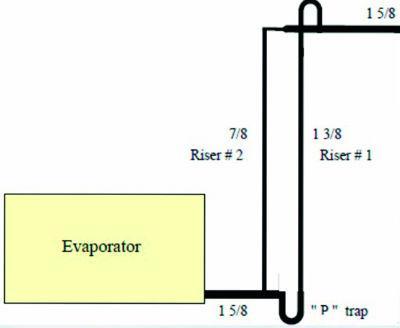

- Then comes the issue of elevators or "raisier" that guarantee to climb to partial loads. In Figure 1 we find an example of elevators in an installation.

Figure 1. Single and double riser

- Refrigeration loads, selection of equipment: The bad practice of not getting to the detail of the real refrigeration loads; the market usually mentions Btu/Hr per linear meter of display, not understanding that each manufacturer has its specific curve as well as the developments of the manufacturers of new products lead to each time designing with lower DT in the evaporators and thus achieve higher evaporation temperatures (TSS) with greater energy efficiency. This is so important not only that the equipment is able to achieve the final temperatures but in having savings of the order of 2 to 3% for each pound that the suction pressure is higher and this is in ALL the group of compressors that work for that condition.

Just to cite a comparison: Two types of furniture that are connected to the same suction group that evaporates at 15F in MT

- While a dairy fridge demands 1851 BTUHR/FT linear

- One of the meats served can be in the order of 300 BTUHR/FT LienalLineal

And this changes from manufacturer to manufacturer with each specific development of evaporator surface area, combined with air movement, etc.

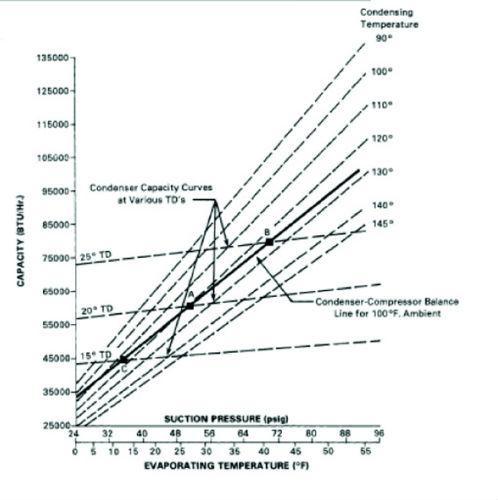

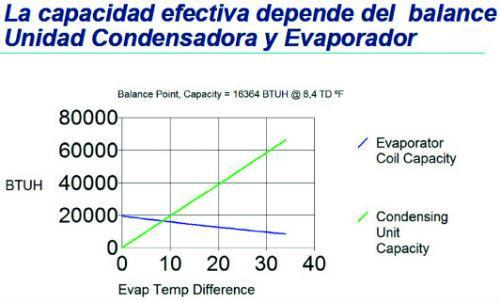

- Selection of equipment: these are not designed for a nominal capacity since their final performance will depend on the appropriate combination between each of them, Note in figure 2, that the real operating point of the "system" is the intersection of variables such as TD, (temperature difference between air and refrigerant) Evaporation temperature, and condensation temperature.

Figure 2. System Operating Point

Installation

As in many cases there are no designs made by specialized third parties, the errors here can be of different kinds:

1. Bad installation practices: Appropriate welds and a permanent stream of nitrogen inside the nets as long as they are welded prevents the formation of slags and copper flakes as illustrated in figure 3 where the difference between an installation with the use of nitrogen run and the one that did not use it is appreciated.

This fact that is not taken into account much by the cost of nitrogen, but from the new refrigerants and new mixtures that force the use of synthetic oil POE this is highly solvent and removes the particles that are deposited there, remain in suspension with the oil and go on to deposit and obstruct holes of expansion valves, of capillaries or even the same lubrication ducts of the compressor with the risks of damage that this implies.

Figure 3. Difference in internal finish of copper pipes. difference between welded tubes with and without nitrogen current.

Other usual bad practices of the installation go through very common themes: Such as poor support and inappropriate fixation to avoid causing vibration fractures, the omission of slopes in the sections of horizontal pipes in the direction of the compressor, poor installation of thermal insulation causing infiltrations of moisture and condensation of the pipes.

A determining factor in the success of an installation and that is generally not taken with importance are the tests of start-up and tuning of the system among the most important are:

- Evacuation and dehydration. These must be done until both positive pressures are achieved and sustained at 1.5 times the working pressures for 24 hours and the vacuum at 250 microns.

- Staggered system start-up. Establish a step-by-step decrease in the temperatures of the rooms and refrigerators to make the entry into operation of the system more homogeneous.

- Set-up of the system overheating adjustment of the expansion valves. This is one of the tests that are omitted at the start-up of a system and that can avoid subsequent problems such as the return of liquid to the compressors and instability in the temperatures of the products in the display refrigerators or cold rooms.

From the operation

A good design and a correct installation of a refrigeration system for food cold is not enough; the operation that the end user gives to the system is as or more relevant and are those that good installation practices can combat, and that negatively impact the reliability, stability and efficiency of the system. Some of those bad operating practices are the ones mentioned below:

1. Bad or inappropriate loads in the levels of the refrigerators or chambers, preventing an adequate circulation and / or retronó of air which in the end translates into freezing, risk of damage to the compressors, low evaporation temperatures and penalty in the efficiency and loss of the cold chain due to heating the product.

Figures 4 and 5 show very common cases in supermarkets and supermarkets where the capacity of refrigerators and cold rooms is exceeded.

Figure 4. About capacity in a display fridge.

Figure 5. About capacity in a cold room.

Figure 6 shows problems caused by poor air circulation in a display refrigerator.

Figure 6. Generation of ice in an evaporator.

2. Tightness and good use of camera doors

The excessive opening of the doors as well as their lack of closure are the culprits of ice formation, infiltrations to evaporators with risks similar to those of refrigerated furniture when they make ice, return of liquid and risk in the compressors. Figure 7 shows the consequences of misuse of the doors of a cold room, causing ice formation.

Figure 7. Ice formation at the entrance of the cold room.

3. Closing the curtains of the display refrigerators

Not closing the curtains of the display refrigerators is detrimental to the efficiency of the system since at night by not having in many cases the operation of the air conditioning system or ultimately due to the high humidity of the area, intensifies the operation of the cold plant increasing the hours of operation of the compressors.

* Giovanni Barletta is the Technical Manager of Emerson's Andean, Caribbean and Central America Area, and current president of the Colombian Association of Air Conditioning and Refrigeration (ACAIRE). You can be contacted at email: [email protected] - [email protected]