Application of CO2 (R-744) as a refrigerant in subcritical cycles and transcritical cycles.

Application of CO2 (R-744) as a refrigerant in subcritical cycles and transcritical cycles.

by Ernesto Sanguinetti Remusgo*

With ChloroFluoroCarbon (CFC) refrigerants withdrawn from the market and then HydroChloroFluoroCarbon (HCFC) refrigerants in the process of recalling, the problem of damage to the terrestrial ozone layer is on its way to its solution. Now we are facing another environmental challenge: The "greenhouse effect", which is a phenomenon produced by a series of gases that accumulate in the atmosphere, within which are the refrigerant fluids, and that cause a part of the radiation emitted by the earth to the outside to be reflected back to the surface of the planet.

This effect is causing an increase in earth's surface temperatures, known as "global warming." This increase in temperatures is affecting our planet, causing a change in climate whose most notorious effects are desertification, increased extreme weather events and rising sea levels.

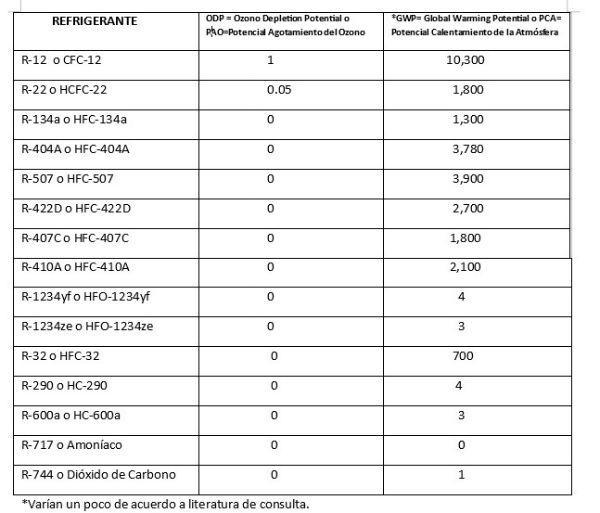

Refrigerant fluids use the indicators or coefficients GWP (Global Warming Potential) or GWA (Global Warming Potential), to know how harmful the refrigerant is and if it contributes much, little or nothing in global warming. The indicator is based on the comparison with CO2 which is the main contributor to this phenomenon, which is given a GWP = GWP = 1.0. This is an important fact, since there are currently refrigerant gases with GWP or GWP close to 2,000 (such as R-410A), that is, 2,000 times more harmful to global warming than CO2.

According to some reliable sources of information, if in 2004 fluorinated refrigerants were responsible for 1.3% of global warming, by 2050 their responsibility could amount to 8%. Therefore, the regulations imposed in this regard serve to stop this progressive increase and get used to using sustainable refrigerants (GWP or PCA = 0 or very small), as well as a replacement for refrigerants that have high GWP or PCA that are loaded in equipment with many or few years of operation, as well as in the loading of new equipment.

As a reference we show the following table where the effects of some refrigerants that are no longer used, others in the process of disappearing, current refrigerants and future refrigerants, on the ozone layer and on global warming appear:

Table 1.

Regulations, such as the Kigali Amendment in Rwanda, Africa (2016); which refers to the reduction in the consumption and production of HydroFluoroCarbon (HFC) refrigerants of high GWP; they bring with them a significant market movement in search of alternative refrigerants or substitutes that keep the market competitive and safe, while at the same time there is concern for energy efficiency and sustainability.

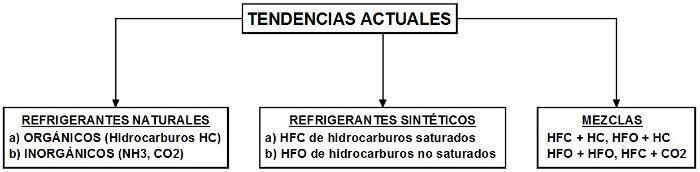

The alternative that is gaining strength within the current and future trend of refrigerants are Natural refrigerants, which are biodegradable fluids present in nature that do not contribute or do so on a minimal scale to global warming.

Figure 1.

Within the natural refrigerants we have Hydrocarbons (Propane, Butane), Ammonia and paradoxically, as explained about "global warming" the one that has a lot of future in commercial and industrial refrigeration is Carbon Dioxide or CO2 or R-744, which is not a new refrigerant because it was used from the late nineteenth century to the beginning of the twentieth century, being displaced by CFC and HCFC refrigerants, but with the environmental problems that these fluids have created, then the improvement in the manufacturing technology of compressors, valves, controllers, safety devices and installation procedures has become more and more topical and is being used more and more.

So far, in the "food cold chain", including supermarkets, the most widely used systems are those of direct expansion with refrigerants R-404A and R-507 (we must point out that there are still systems with R-22) for both low and medium temperature, with their respective condenser acting as independent plants, each with its own refrigerant, each plant being able to have a single compressor or two or more in parallel (racks).

As an improvement and that until now is widely used, the plants appeared with several compressors or "racks" of compressors in parallel but with a group of compressors destined to low temperature and another group destined to medium temperature, having a single remote condenser for the entire direct expansion system.

These days we are facing the analysis of seeing all the possibilities of replacing these refrigerants that have high GWP or PCA by refrigerants with zero or low GWP and / or gas mixtures, to extend the useful life of the facilities while the replacement time arrives. The replacement has a very high economic potential due to the large number of current installations with R-404A, R-507, R-22 since it is not simply a matter of changing refrigerant and using CO2 or another natural refrigerant immediately, but the entire system must be changed.

New installations that opt for natural refrigerants and CO2 in particular will not have that problem, they are already designed and equipped with components for them.

Subcritical and Transcritical

CO2 can be used in two ways: System with sub-critical cycle and system with transcritical cycle:

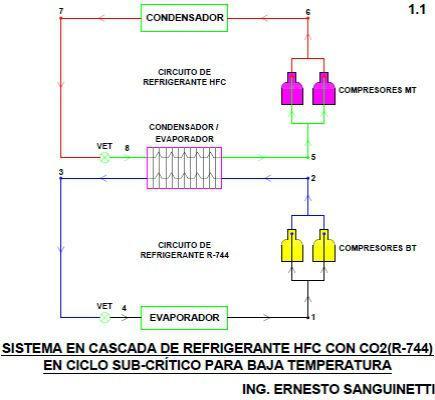

A.-When it condenses below the critical point it is called a system with a subcritical cycle.

To condense CO2 below its critical point (PRESSURE = 7.382 MPa = 73.82 bar = 1,070 psia, TEMPERATURE = 304.1°K = 31°C) another refrigeration system or circuit with another refrigerant (R-134a,R-290, R-1270, R-717) must be used so that the evaporator of this system cools the condenser of the CO2 system or circuit and condenses it "in cascade".

The diagram shows a sub-critical CO2 system for low temperature application "cascade" with another system that uses HFC refrigerant (can be R-134a).

Since 2015 in Peru we have installed and have worked so far systems of this type in twelve supermarkets to obtain both medium and low temperatures in food displays and cold rooms.

Figure 2.

B.-If the process prior to condensation is carried out in a "cooler" (no longer called a condenser) that is at a pressure and temperatures higher than the critical one, it is called: system with transcritical cycle.

CO2 has a higher critical temperature than normal ambient temperatures. In this transcritical case, unlike the common circuits that have a constant temperature in the condensers, they have a variable temperature as heat is exchanged to cool the CO2. We call this heat exchanger that can be cooled by ambient air or water "chiller" and the working pressures are very high (between 90 and 100 bar or between 1160 and 1450 psia).

It is necessary to take into account the temperature of the CO2 gas at the exit of the "cooler" because for example with an outlet temperature of 35 ° C and being in the range of pressures that we indicate a better Coefficient of Operation or Performance (COP) of the system is reached. If you work with pressures higher or lower than that range, the COP will decrease with the corresponding loss of energy efficiency. It should also be noted that if the outlet temperature changes to 40°C, the corresponding pressure must be higher and if it is 30°C the pressure will be lower.

When the construction of hermetic and semi-hermetic compressors was improved, and in addition, oils were found that have good lubrication properties in systems with CO2 in both low and high temperatures, while withstanding low and very high pressures, the possibility of making a two-stage compression system of CO2 or as they call it to use "booster", instead of working "in cascade" with two refrigerants became attractive because a single natural refrigerant would be used throughout the refrigeration circuit.

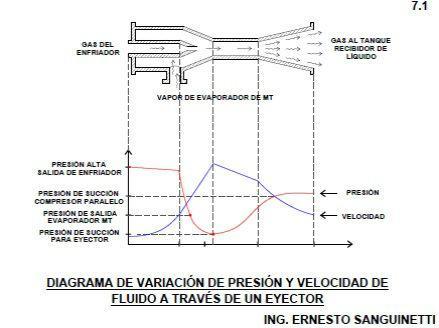

There are many variants of this system: two-stage compression with or without "parallel" compressor, with "By-pass" valve, use of exchangers to improve sub-cooling and others. A very important variant was the incorporation of ejectors that reduce the number of compressors or their size because the property they have is used to compress refrigerant gases and thus reduce the energy needs in the high temperature compressor plant, improving the energy efficiency of the entire system. See diagram showing what happens in an ejector:

Figure 3.

With the transcritical system, the limitations of current refrigerants that damage the environment are overcome while improving efficiencies in refrigeration facilities, but as in any investment, both the cost of acquisition and that of the installation of the system must be analyzed, to know the rate of return with energy saving.

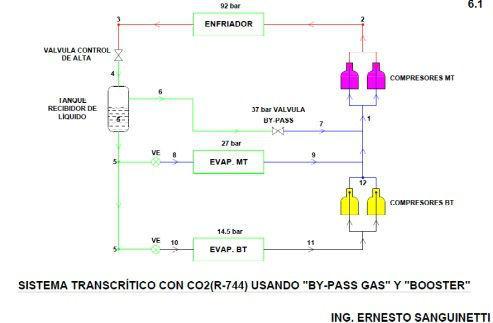

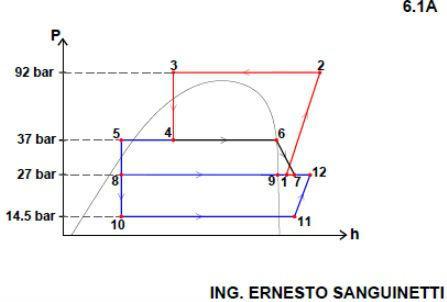

In the diagram that follows we show a system with simple transcritical cycle for applications in medium and low temperature in the food cold system of a supermarket, with its diagram Pressure vs. Enthalpy. This system is recommended for areas with cold climates.

Figure 4.

Figure 5.

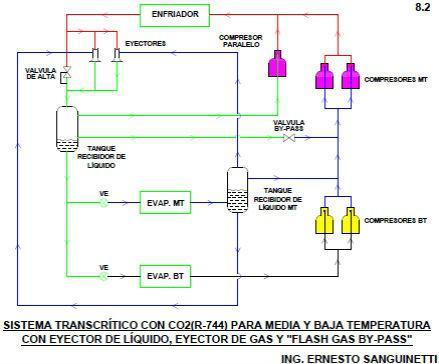

The following diagram shows a system with transcritical CO2 cycle improved with ejectors and parallel compressor, in a refrigeration system to obtain both medium and low temperatures. This system can be applied in areas with cold climates and semitropical climates.

In Peru, at the end of 2018 we installed and have operated the first transcritical system of this type applied in the food cold system of a supermarket to obtain medium and low temperatures in the various food displays and cold rooms. Throughout this year we hope to install other similar systems.

Figure 6.

* Eng. Ernesto Sanguinetti Remusgo- Manager of the Engineering Division of COLD IMPORT S.A. – Lima - PERU.

Excelente información,Gracias por compartir, Saludos desde Cali,Colombia.