The first part of this advanced guide to energy design for supermarkets offers best practices and recommendations to optimize efficiency in supermarkets with areas between 25,000 and 65,000 ft2 (7,600 and 19,800 m2).

By Eng. Giovanni Barleta and Eng. Sebastián Madariaga*

The high energy costs, the permanent expansion of the retail sector, supermarkets and experience centers, as well as the need to be competitive in a segment with a limited margin, has promoted the emergence of many trends, strategies and with it literature around energy saving, and how to optimize the shopping experience for the end user, who is increasingly demanding in terms of thermal comfort. cold chain, impact on the environment in this business segment.

Among all the existing literature, the AEDG (Advanced Energy Design Guide) stands out, which in particular proposes how to save 50% of energy in supermarkets and department stores.

Figure 1. Advanced Energy Guide for Supermarket Design

This advanced guide to energy design for supermarkets is a compendium of best practices and recommendations for optimizing efficiency in supermarkets with areas between 25,000 and 65,000 ft2 (7,600 and 19,800 m2).

This guide was developed by ASHRAE members on the 138 committee representing the integration of other organizations, such as, the American Institute of Architects (AIA), the Lighting Engineering Society of North America (IES, IESNA), the U.S. Green Building Council (USGBC), and the U.S. Department of Energy (DOE). This guide seeks to provide guidance and recommendations to reduce total energy consumption by 50% or more, in supermarkets, even those that are already high performing in compliance with ASHRAE Standard 90.01-2004. This 50% energy saving is determined based on the total consumption of the building.

While the guide is designed for supermarkets with areas between 25,000 and 65,000 ft2 (7600 and 19800 m2), it also applies to smaller or larger stores with similar types of spaces. Among the types of spaces included in the guide are dry goods areas, meat areas, bakery, bathrooms, mechanical rooms, offices, corridors and storage areas, among others. The guide does not cover the parking area, water treatment area and/or waste areas; It focuses on new construction, but the recommendations are also valid for large remodels.

At the same time, the guide promotes the best environmental conditions for the buyer with respect to indoor air quality (IAQ), the improvement in the visual effects of the merchandise, promoting an increase in sales and, of course, savings to the owner, using multidisciplinary resources and tools.

To achieve the objectives of the guide, it is essential that an integrated design process is carried out between the different disciplines, since each of them has an impact on HVACR systems, such as: lighting, building orientation, internal distribution, among others. Among those involved in the integrated design process are

· Architects

· Corporation Representatives

· Engineers

· Contractors

· Commissioning Authorities

· Operators

· Other designers (HVACR experts and kitchens)

The veracity of this methodology of the integrated design work could be demonstrated by doing an energy simulation, which was developed and analyzed through an hour-by-hour analysis model, where a 45,000 ft2 (13700 m2) store was carefully designed as a representation of a typical store (built and operated under the highest standards of efficiency).

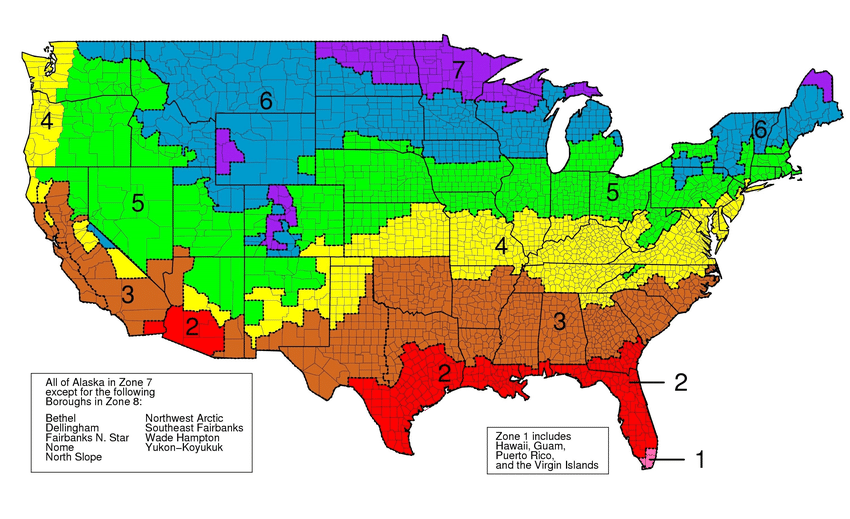

Sets of 2 simulations were performed. In the first of these, the store was studied with the minimum requirements according to Standard 90.01-2004; In the second simulation, the same store was studied applying the recommendations of the guide. Each set was simulated in the 8 climate zones adopted by the International Energy Code Council (IECC) and ASHRAE, which were then subdivided into wet and dry regions for a total of 16 climate zones, as shown in Figure 2.

Figure 2. Climatic Zones object of study and simulation.

Figure 2. Climatic Zones object of study and simulation.

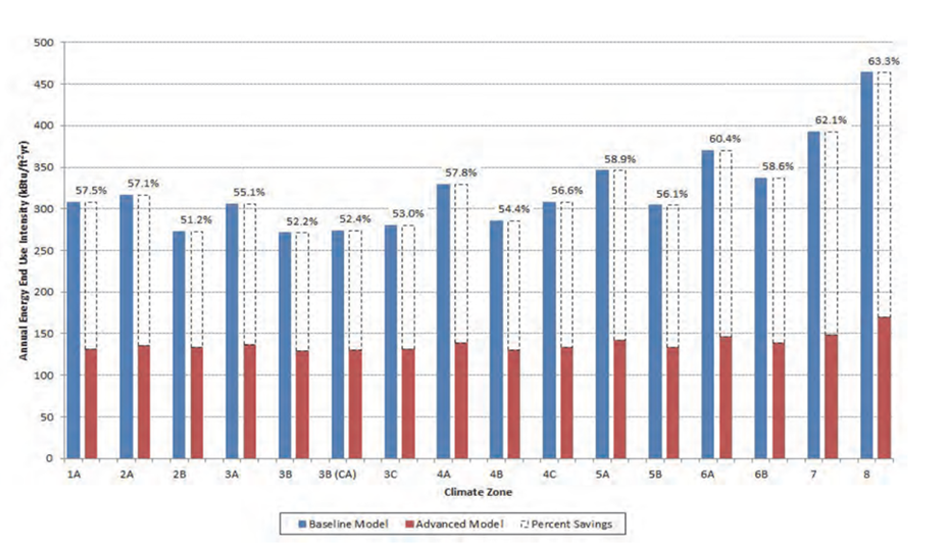

The total energy savings vary according to the area, the HVAC system and the type of store, but in all cases the savings are at least 50% compared to the 90.1-2004 standard, as evidenced in Figure 3:

Figure 3. Results of efficiency improvements compared to applying the guide vs a high-performance store.

Due to the impact of climate, not all strategies apply to all climate zones, and the outcome of the guide depends on the area, where certain recommendations apply and not in some. Although the study and simulation was done for areas in the USA, we found that many of the climate profiles are assimilated to several in our continent and particularly in Caribbean cities and countries zone 1 is similar to our tropical, coastal and torrid climates.

The guide has a very broad scope that is given by a total of 190 recommendations, which are divided by types:

· Enclosure Components

· Daylighting (DL)

· Electric Lighting (EL)

· Load Connected (PL) Components

· Kitchen Equipment (KE)

· Refrigeration Equipment (RF)

· Service Water Heating (WH)

· Systems & Equipment (HVAC)

· Quality Assurance (QA) Components

· Additional Savings (RE) Components

This first part of the article focuses primarily on cooling (RF) components. These cooling components are further divided into sub-components, such as:

· Condenser selection and control

· Compressors

· Display Cases & Cold Rooms

· Heat recovery

We will mention shortly only a few recommendations and analyses of the 31 that refer only to Refrigeration Equipment (RF).

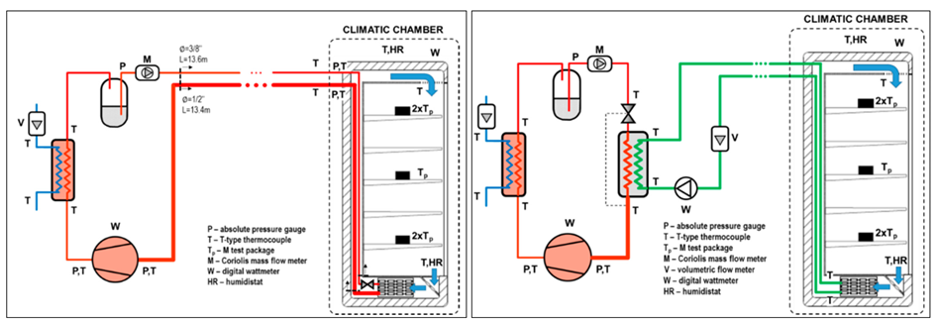

Direct and indirect cooling systems have emerged as an interesting option given that they promote a significant reduction in the amount of refrigerant in the system, as well as a decrease in leakage emissions and a benefit in direct emissions.

Direct systems are mainly characterized by:

● Be the most widely used and most common system.

● Have long pipeline routes.

● Have a high refrigerant charge.

● Having losses in the system due to friction in pipes mainly in suction.

● Its leakage level ranges from 35 to 50% of its total load.

While indirect systems (secondary fluids):

● They began around 1980.

● Preferably use glycol.

● They reduce the charge of the refrigerant, thus reducing refrigerant costs and greenhouse gas emissions.

● However, they have a negative impact on your energy performance, which:

○ It is due to lower suction pressures (only suction pressure).

○ Can be minimized using recirculated CO2

○ It has parasitic loads on pumping.

○ Features a single glycol temperature (half temperature).

○ Has sensible heat gains (no phase change in the inner coils)

○ It is characterized by lower heat transfer properties.

○ Requires large circulation pumps.

○ Has heat gains per pipe run

Figure 4. Direct vs Indirect Cooling Systems.

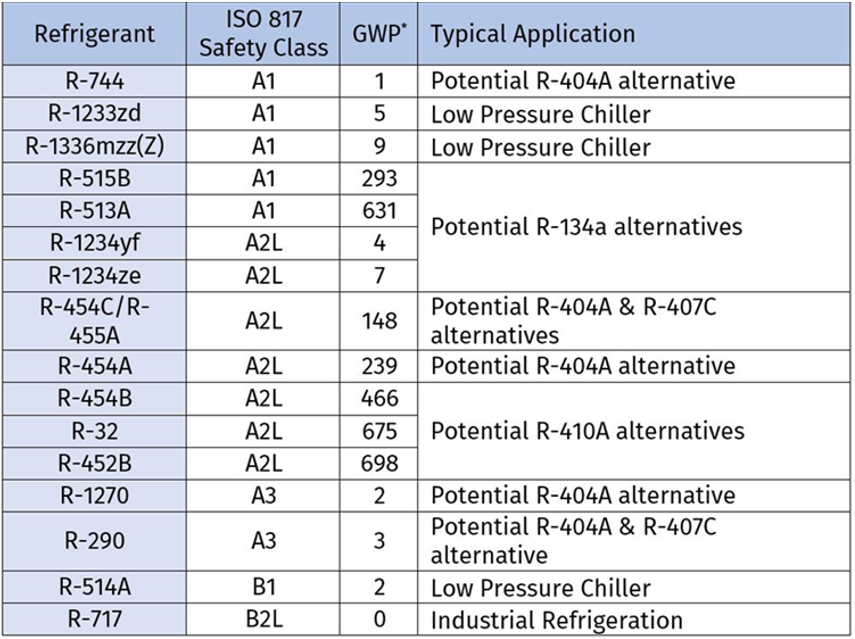

These solutions go hand in hand with the analysis and alternatives of the type of refrigerant and the essential considerations with respect to these: (Figure 5).

● Global Warming Potential (GWP): The impacts of refrigerant selection on GWP are significant and refrigerants with lower GWP values should be preferred.

● Refrigerant Safety Rating (A2L/A3): The refrigerant safety rating is based on the toxicity and flammability of the refrigerant. A2L refrigerants are mildly flammable and A3 refrigerants are highly flammable, so special precautions should be taken when using them.

Conclusion

Direct expansion systems have higher energy efficiency, (evaporation at a higher TSS and no pumping cost) but also a higher refrigerant charge and a higher risk of leakage. On the other hand, indirect expansion systems have lower energy efficiency and a higher pumping cost.

However, the above is a general premise, there are variables that can minimize this lower efficiency, such as heat exchangers with low DT, recirculated refrigerants such as C02 with a higher heat transfer capacity, variable speed pumps working at variable loads, refrigerators with low DT requirements in glycol, among other measures. It would be subject to a TEWI methodology to verify its real equivalent impact between direct and indirect emissions.

Figure 5. Properties of refrigerant replacement alternatives.

Single Suction Group or Dedicated Suction: Because supermarkets have a wide range of temperature requirements for different products, it is recommended to group compressors into several suction groups. Suction pooling refers to the practice of grouping evaporators that have similar evaporative pressure requirements and assigning a dedicated compressor (or compressors) to these evaporators.

A more efficient system will have separate groups of compressors for low-temperature evaporators and for medium-temperature evaporators. However, designers should also keep in mind that, depending on the specific dynamics of a system, it may not make sense to create a separate suction group based solely on the temperature of the evaporators. There must also be sufficient load in the different temperature groups to justify splitting the suction.

A specific recommendation is to create additional suction pools when the saturated suction temperature (SST) is more than 5°F below the saturated temperature of the hottest evaporator (SET) in that pool.

Although it results in a greater investment, in many cases there can be up to two groups at low temperature and three at medium temperature.

Floating Suction: In addition to the efficient design of the suction units, additional energy can be saved by "floating" (increasing) the suction pressure during system operation. Like the reduction of condensing pressure by floating condensing strategy, increasing the floating suction pressure helps to reduce the total load of the compressor during operation.

Floating suction pressure can typically be applied to suction groups designed at 25°F or lower SST.

To take advantage of these savings, it is necessary to monitor the temperature of the product (typically done indirectly by monitoring discharge or return air flows in evaporators) and is necessary to ensure that product temperatures are not compromised as evaporation temperatures float. Logic is also required on the compressor controller to evaluate product temperatures and adjust SST set points for the compressor cycle.

Note: the second part of this special will be published in the next issue: 26-6 Nov/Dec.

* Eng. Giovanni Barleta, President of ACAIRE. International Consultant in HVACR systems. ASHRAE Distinguished Speaker.

* Eng. Sebastián Madariaga. International Designer and Consultant.