The air conditioning solutions for the planting of marijuana, far from being an allegory to the entheogenic use of the plant, respond to a growing and profitable arm of the pharmaceutical and cosmetics, being, in addition, a line of high interest and development for the HVAC sector.

By Iris Montoya

Next I will break the protocol of "serious" language, without neglecting the technical rigor, since debating Cannabis Sativa deserves to be narrated with a touch of histrionics, given the controversy caused by its recreational use in our territory, as well as its undeniable psychotropic effects and proven health benefits. Perhaps if we read grass, the grass will reveal itself to us.

Some time ago I read, in the Marketing report of Integra Realty Resources (IRR) entitled "VIEWPOINT: 2018 Commercial Real Estate Rends Report", that a marijuana crop of 304 square meters (1,000 ft2) occupies HVAC equipment with up to 14 tons of refrigeration (TRF), a fact that led me to question whether this sector represented a potential VIP client for the industry. Especially when an annual growth of around 16% is projected.

Now, in the face of an audience not necessarily trained in the planting of marijuana - in which I include myself - the knowledge of this process is similar to the general domain on the maternity of chicks; In theory we all know how it works, but the details related to times, temperature, optimal space, most used equipment, care and even gender, are listed as an unknown universe.

And beware, the allegory to gender is not casual, because, just as chickens must be sexed to know if they will be rooster or hen, there is male and female marijuana. As the Leafwell portal explains: "Female cannabis plants are considered important because they produce buds, which contain trichomes that produce high concentrations of cannabinoids, terpenes and flavonoids", although industrially the so-called "males" are also maintained to keep the unique genetic profiles alive and add variation to the gene pool.

Now, a chick is born in 21 days, but "La Maria" takes its time, 90 days in general, so we will have on average 4.29 chickens while growing and growing a marijuana plant. This erect herb of the family of the order of roses and with flowering stage, represents, according to the World Health Organization (WHO), "the most widely used illegal drug". Hence, unlike chicks, its possession and commercialization is prohibited throughout Latin America, except Argentina, Chile, Colombia, Mexico and Peru, where it even has certain restrictions.

This plant, which for Rastafarians is a sacred element found in the tomb of King Solomon, created by their god to heal believers and "reveal their ways", for the moment will remain at the center of heated political debates, as many governments seek to establish the limits of its medical and recreational role. marking the path of its usability for citizens. But what are the air conditioning factors that Ganjah needs to grow prior to consumption?

Millimeter control and air quality

According to the lamota.org portal, "temperature and humidity will be decisive to achieve success in the crop; Its parameters will change according to the evolution of our plant. In the seedling stage, the temperature should be between 20 and 25 °C, while the humidity should be high, between 65 and 70%. This allows that since the roots have not yet developed, the water is absorbed through the leaves."

For Cultiva Systems, an American company that markets customized systems for air conditioning in marijuana crops, focused on indoor crops, with variable load capacity ranging from 10 to 45 tons, "urban agriculture is not only better for the environment, but being able to control the elements creates healthier and stronger plants that produce more crops."

In the words of Cultiva "superior air quality also promotes growth, eliminating the need for fertilizers." As more states and countries adopt laws on recreational marijuana, stricter purity standards will be established.

If you have grass add a D Greg Crumpton, ASHRAE committee member and Vice President of Service Logic, a nationwide commercial, industrial and mission-critical HVAC Services company, in his article "Back to Basics: The ABCD of HVAC for Indoor Cannabis Cultivation" comments that just as the acronym HVAC was added the R for refrigeration, now, "with the ever-increasing discussion and actual work in the cannabis growing space, now is the time to add a D for dehumidification."

Greg Crumpton, ASHRAE committee member and Vice President of Service Logic, a nationwide commercial, industrial and mission-critical HVAC Services company, in his article "Back to Basics: The ABCD of HVAC for Indoor Cannabis Cultivation" comments that just as the acronym HVAC was added the R for refrigeration, now, "with the ever-increasing discussion and actual work in the cannabis growing space, now is the time to add a D for dehumidification."

In the text, Crumpton highlights temperature and humidity settings by grow room type. For the "mother room" which is the space that serves as a gene bank to preserve cannabis varieties, it indicates a temperature of 75 ° F / 23.8 ° C and relative humidity (Rh) of 60%. For the propagation/cloning room, which is where cuttings (stem fragments) that are in the process of sprouting roots and becoming a standalone plant are taken, the optimal measurements are 80°F/26.6°C and 90% (Rh).

In the vegetative room, which is where cuttings already have a healthy radial size and will be allowed to grow three-quarters of their final size, ideal conditions are 80°F/26.6°C and 40% to 60% (Rh). Already in the flowering room, dedicated to the plants to take out their flowers, that is, the part that is demanded for both recreational and medical use, an environment of 70 to 80 ° F / 21 to 26.6 ° C is sought and the relative humidity of 40% to 60% is continued.

At the end of the process, in the curing room, which is where the fully mature flowers of Cannabis are cut, prior to the drying room, 65 ° F / 18.3 ° C and 45% (Hr) is recommended. After drying, it could be moved to an adjustment room to remove some unnecessary leaves, where the environment should be at 75 °F/23.8 °C and 50% (Rh), the same conditions suggested for the packaging process.

It should be noted that for Crumpton there are many variables, as well as opinions, techniques and styles for all periods of the growth cycle of the grass, poorly known in Colombia as "the bush that kills", but from there he emphasizes that "the constant remains that the environmental conditions that are required for each phase of life and the process are key to productivity, measured in product performance, and are indeed related to the commercial success of the industry and the ability of the HVAC/D communities to serve the ever-growing industry well."

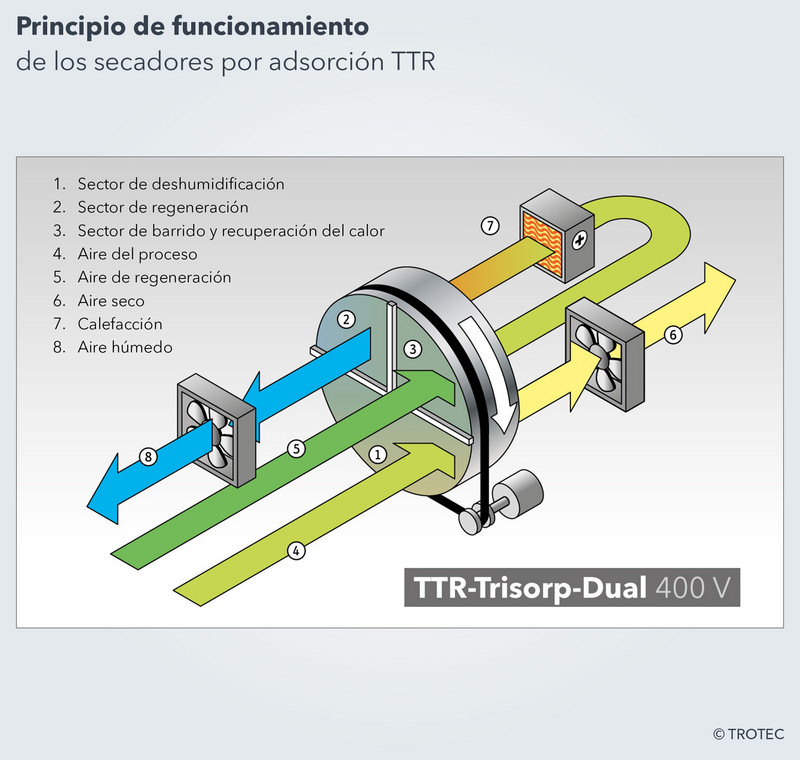

In this order of ideas, the company Trotec, which has German origin and is based in Spain, manufacturer of air conditioning and air equipment for the industry, among other verticals, points out that "indoor cultivation, in growing rooms or special greenhouses, as well as the drying process after harvest, place great demands on climate control and the dehumidification technology used".

Trotec also highlights some advantages of dehumidification and controlled drying in cannabis cultivation, ensuring that it promotes root and plant growth, "only with the optimum humidity in each of the different phases of growth, cannabis plants will flower properly; Helping to give higher yields during the flowering phase makes plants less susceptible to pests or diseases," which increases the yield and minimizes losses.

For this company, dehumidification leads to an accelerated drying process, which reduces production times and "optimizes the quality of the aromas of the buds". In this sense, it suggests the use of condensation dryers which can reach dehumidification capacity of up to 500 liters per day (4,600 m³/h of air volume).

These equipment operate thanks to a compression refrigeration system to circulate the refrigerant through the blender and evaporator. "The air sucked in during air circulation passes through the evaporator, cools below its dew point temperature, condenses into water droplets and is discharged into a collecting vessel. Next, the cold, dry air is conducted through the hot blender, heated using the process energy, and finally returned to the room as hot, dry air, where it re-absorbs moisture. This heat pump principle ensures optimum humidity with minimal energy cost."

Design for "cannabis air conditioning"

As has been evident, in this approach to the environmental requirements of cannabis planting, air conditioning, in addition to playing a vital role in production, is a variable that has a precise function.

In that sense, Cultivation Sector Consulting LLC, a company based in Makawao (Hawaii), dedicated to consulting for Cannabis businesses, covering cultivation, extraction, retail and compliance documentation, highlights the importance of the design of the facilities, in light of the fact that "some cultivation companies have failed due to poorly considered designs and mechanical systems that are difficult to change once the site is operational."

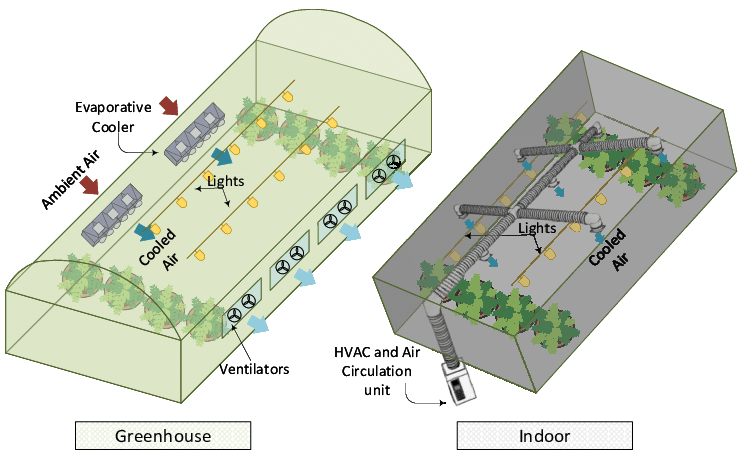

For Cultivation, the HVAC system must be "easy enough to repair, have parts and technical support readily available, an easy-to-use control system and a good warranty." He also suggests that air handlers and mechanical equipment should not be inside grow rooms, only ducts should be inside, "this is so that mechanical equipment does not pose a biosecurity risk to plants and/or generate additional heat within the space." In addition to avoiding contamination in the crop when doing maintenance and changing filters. "Difference in energy use in greenhouse and indoor cannabis growing operations."

Image credit: Mehboob, Nafeesa and Farag, Hany and Sawas, Abdullah. (2020). Energy Consumption Model for Indoor Cannabis Cultivation Facility. IEEE Open Access Journal on Power and Energy.

The company proposes as an ideal scenario that each grow room has its own duct system "so that mold from one room and system cannot infect plants in another room."

In general, the suggestion of this company is that the project, in addition to construction factors that can go from scratch as considered by the client, take into account a work team made up of an architect with experience in cannabis facilities; a mechanical engineer who designs "backup power systems and HVAC redundancy so that mechanical failures do not mean the immediate ruin of your precious plants."

A cannabis cultivation consultant, who will indicate all the details regarding cultivation methods, costs of the various options, ease of use, pros and cons, and help design a reliable system before you have built the walls in the building. A structural engineer, who helps "determine the weight capacity of the building in case HVAC equipment or solar panels need to be mounted on the roof." An environmental engineer, who is in charge of "calculating the needs and creating systems for the management of wastewater, odors and any other potential environmental hazards."

Regarding the equipment, the company suggests having referenced the suppliers of shelves (the "furniture" on which the plants sit); the company in charge of installing the HVAC and dehumidification solution; the company that will provide control of the irrigation/fertigation system; and, finally, the company that will respond to the lighting requirement.

Finally, Cultivation Sector Consulting highlights that in new cannabis cultivation projects the most common mistakes are insufficient investment in mechanical systems, which is given by relying "on basement growers or HVAC companies without experience in cannabis facilities to design and size their systems"; having infected clones, an issue that can occur when the crop is started not from the seed, but from parts extracted from other plants already mature to replicate them; and trusting the wrong people, that is, giving entry to suppliers without experience or biased towards their products.

What does ASHRAE say about weatherizing the speck?

The publication "Plants are not people: load calculations for cannabis cultivation facilities", located in the ASHRAE Journal (Vol. 62, No. 4, April 2020), includes the indications of two experts of the organization in this regard.

Nadia Sabeh, Ph.D. in Agricultural, Biosystems and Remote Sensing Engineering, ASHRAE Member and President of Dr. Greenhouse, Inc. He indicated that cannabis, being a plant, is a living and dynamic organism that poses to engineering the challenge of designing, manufacturing and developing equipment that can respond to a changing environment throughout the life of a plant. "We need monitoring and control systems and equipment that can respond to and predict changes in the environment."

Nadia Sabeh, Ph.D. in Agricultural, Biosystems and Remote Sensing Engineering, ASHRAE Member and President of Dr. Greenhouse, Inc. He indicated that cannabis, being a plant, is a living and dynamic organism that poses to engineering the challenge of designing, manufacturing and developing equipment that can respond to a changing environment throughout the life of a plant. "We need monitoring and control systems and equipment that can respond to and predict changes in the environment."

In that sense, Stephen Roth, another member of ASHRAE and president of Carmel Software, said in front of the calculation of HVAC loads for cannabis cultivation facilities, that in these they should consider that "latent loads are the driving force. Therefore, using a conventional load calculation software tool for cultivation facilities may produce inaccurate results."

In that sense, Stephen Roth, another member of ASHRAE and president of Carmel Software, said in front of the calculation of HVAC loads for cannabis cultivation facilities, that in these they should consider that "latent loads are the driving force. Therefore, using a conventional load calculation software tool for cultivation facilities may produce inaccurate results."

That is, designers can't perform the calculations for spaces where marijuana is grown in the same way they do with conventional office buildings. In addition, he added that peak HVAC loads should be considered for the different stages of the plant.

Mature Cannabis Seeds

"Dry-bulb cooling benchmarks and relative humidity will be higher when plants are smaller. When plants grow, relative humidity set points will decrease. Different types of grow rooms will also require their own individual HVAC systems."

In that line of ideas, Sabeh explained that many growers look for low air temperatures and / or low relative humidity, to avoid the action of mold, but this results in a high VPD condition, could be detrimental to the crop as it can stress the plant.

Finally, the section "Drying and storage of selected agricultural crops (TC 2.2)" of the ASHRAE Manual (2019 version) for HVAC applications must be taken into account when generating a design, in addition to taking into account the variables required by the growth of marijuana.

A matter of grass, a question of equipment

Following Air2O, a company focused on evaporative cooling technologies and hybrid air conditioning, in the planting of Cannabis "the best alternative to traditional HVAC units for grow rooms are hybrid systems or indirect-direct evaporative cooling systems (IDEC)", as these systems use up to 80% less energy and provide greater flexibility to control airflow, as well as humidity levels.

These equipment are more convenient for indoor planting, because in these spaces their 24-hour operation is required, lights are used to promote growth that involve high energy costs and additionally odor management is required by the high concentration of plants. In addition, "these systems also do not require as much maintenance or create environmental problems compared to traditional units because they do not have GWP, CFC or HFC."

Trotec adds that drum fans are needed, as they guarantee uniform air humidity throughout the dryer, as well as "rapid and careful drainage of water from the plants, which shortens the drying time even more considerably".

Green grass and greenbacks? Shane MacGuill, senior director of nicotine and cannabis research at Euromonitor International, noted in 2020 that cannabis was already a nearly $170 billion global industry, but the legal market was barely worth $30 billion. "As regulation progresses, the legal market is expected to capture 40% of global cannabis sales by 2025 and companies will be able to tap into a large existing user base, as well as feed the curiosity of new adult consumers."

Shane MacGuill, senior director of nicotine and cannabis research at Euromonitor International, noted in 2020 that cannabis was already a nearly $170 billion global industry, but the legal market was barely worth $30 billion. "As regulation progresses, the legal market is expected to capture 40% of global cannabis sales by 2025 and companies will be able to tap into a large existing user base, as well as feed the curiosity of new adult consumers."

In that sense, Euromonitor projected that global sales of legal recreational cannabis would have an increase of 376% by 2025.

In contrast, the research department of Statista, in a publication of February of this year, indicated that this market will go from 7.3 billion dollars in 2020 to 44.8 billion dollars in 2025, where 38.9 will correspond to medicinal use and 5.9 to recreational use.

Given these positive and growth indicators, this market could be considered as the new goose that lays the golden eggs for Latin America, especially because it is a region that could make a profitable transition from illegal to legal planting, which already has favorable climates and abundant labor.

However, and according to the text "Why it has not been so profitable to grow marijuana in Latin America (and who dominates the business)" authored by Luis Fajardo and published by BBC News, on February 23, "what does not appear yet are the great profits that some expected as a result of legalization."

In general, the publication indicates that it has not been possible to reach that dreamed point due to several factors, where it highlights that the illegal market is still stronger than the legal one; that recreational use continue to be discussed at political level; and that local planters have competitive disadvantages compared to multinationals, when accessing licenses and approaching the pharmaceutical industry as a possible client.

One last aspiration

I dare to conclude that, although this episode of the legal development of the Latin American cannabis industry still seems "badly traveled" for local production, which seeks to participate in the great economic projections, as one who seeks to grab the smoke with his hands, with determination but without achieving it, it is understandable that alternatives are devised to achieve success, And that we still aspire that governments facilitate the national appropriation of a slice of that cake, because we are facing a market with an undeniable and attractive potential, which well justifies 'epic' and bizarre actions.

Finally, the response of the HVAC / D industry to the requirements of "the maria" to grow in optimal conditions and achieve high points in its quality, has been irreproachable, since it has developed solutions, design approaches and specific standards for this hallucinogenic client, leaving room for perspectives of improvement and spaces for debate from the regulations.