Analysis, recommendations, processes and tools to carry out a correct welding in this class of systems.

by Jimy Danelli*

In the refrigeration and air conditioning industry, copper pipes welded to different elbows, joints and accessories are used in most cases, which if we do not try to do the proper procedure will produce a series of contaminants that will circulate in the system causing some problems.

Welding is often carried out with filler material, either to join pipes or to install accessories that allow us to divert or reduce these pipes. To make this union or installation we should use certain techniques that allow us to perform this work with the least risk in terms of waste or oxides inside the pipe.

In the atmosphere the air that is breathed is full of pollutants, which at high temperature allow the oxidation of copper, leaving a soot that remains inside the pipe and will give the crankcase of the compressor directly in some cases, in others it goes to the expansion elements, or hopefully to the line filter.

For systems with EEV (electronic expansion valve) that it has micro filters is a whole issue: covers the EEV or limits its movement, hence the inverter systems are so incisive in the issue of welding, this to avoid these and other related evils.

The correct method: let a thread of N2 pass creating an air-free atmosphere, where the pollutants do not make this effect on the copper, that is, there is no oxidation, at this point I think we all agree although sometimes it is complicated to make such welding with this technique, either due to lack of N2 or for practical reasons, location, urgent requirement for the delivery of the work, last welding of a compressor, etc.

But this does not exempt the professional from knowing both the technique and the consequence, sometimes without them and sometimes not, because even in chemical reactions have been found product of this soot, if you can not do this welding at least perform a washing of the pipes once you finish the installation, because the amount of soot is related to the amount of welds, And as I have said on other occasions, line filters are static elements of the system, that is, they do not go out to look for dirt or moisture.

But this does not exempt the professional from knowing both the technique and the consequence, sometimes without them and sometimes not, because even in chemical reactions have been found product of this soot, if you can not do this welding at least perform a washing of the pipes once you finish the installation, because the amount of soot is related to the amount of welds, And as I have said on other occasions, line filters are static elements of the system, that is, they do not go out to look for dirt or moisture.

As personal experience we have found systems with problems even lubrication, in inverter due to lack of welding technique or subsequent cleaning.

Leaks normally occur in welded and threaded joints, even these threaded connections only seal in the conical cup part of the flering and some technicians place Teflon sealants in the nut thread which generates leaks, these travel to the filters of the machines and sometimes are located in the expansion valves, therefore, the points in which it intervenes must be reviewed; If it is not possible to locate the leak with a vacuum system, nitrogen must be loaded under pressure using a leak detector, or only with soap and water, all the welded suspicious joints, and also the threaded ones of the entire cooling circuit must be revisited until the leak is located and corrected.

Leakage correction can be fixed through a weld on the pore that may have been accidentally formed. This happens very often in the evaporator; When welding is applied, it should be performed with nitrogen current at a pressure of approximately 4 lb/in2. If the pore is small, chemical welding can be used, and if the hole is very large, the aluminum pipe can be replaced with copper pipe, the evaporator can be replaced by a new one or simply adjust where the leak occurred.

The first welding materials used in the refrigeration industry were copper and brass, still used for welding certain metals. These materials have the disadvantage of not resisting corrosion well and, above all, of having relatively high melting points.

The addition of a certain amount of silver to copper and zinc alloys has the effect of lowering the melting point, as well as improving their mechanical qualities, as well as their resistance to oxidation and corrosion.

The reduction of the melting point of ternary alloys – copper, silver, zinc – can be obtained by adding cadmium, which also contributes to improving the physical characteristics of the alloy thus made, which allows to obtain welds known commercially as silver solders.

Welding copper is not complicated, however, it requires a little practice to get to make good quality welds. There are two key issues to weld with ease and quality:

Welding copper is not complicated, however, it requires a little practice to get to make good quality welds. There are two key issues to weld with ease and quality:

1. The parts to be welded must be dry; The slightest exit of water from any of the parts will prevent welding.

2. The areas to be welded must be perfectly free of grease and rusts; Copper should look shiny.

Process for proper welding

* Prepare the inside of the accessory, clean the existence of rust and grease with a round wire brush

* Prepare the outside of the tube, clean excess rust and grease with a strip of fine sandpaper

* Apply the flux if necessary at the end of the tube about 25 mm; remove the remnant left by the cut inside and attach the two pieces

* Heat the joint of the middle part of the accessory, not the tube, until the flux begins to crackle

* Touch the edge of the junction with the rod, if melting is ready to weld

* Separate the flame from the joint and insert the rod to cover the joint; This will enter the union by capillarity. A good weld shows silver around the periphery of the edge. You have to be careful: the tube can be hot even when it is far from the joint.

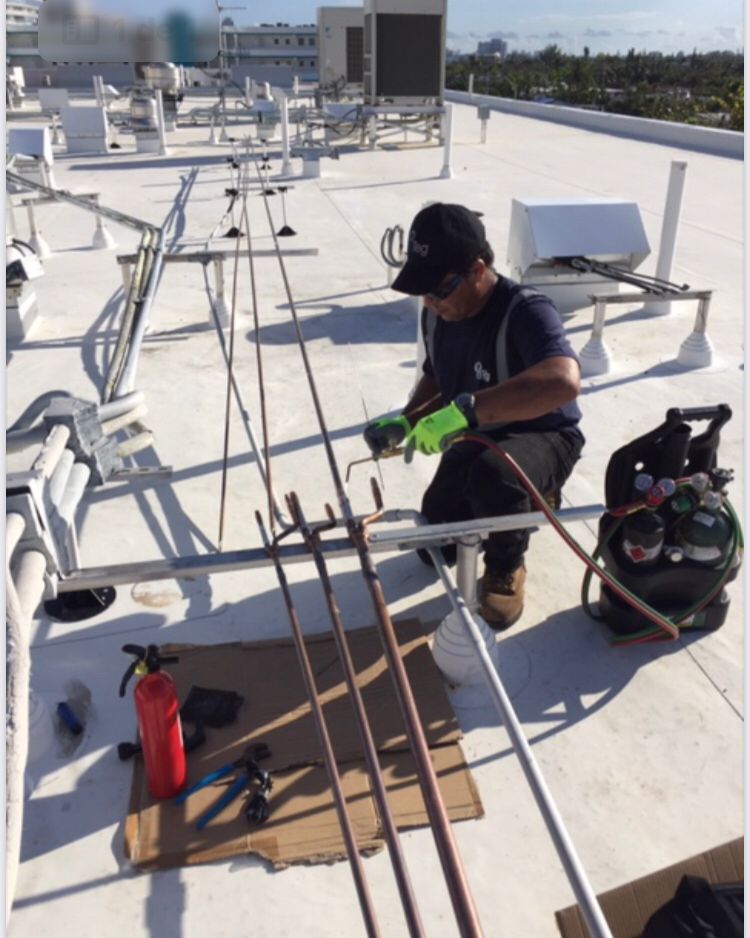

Suitable tools and utensils

a) A piece of fine sandpaper or a wire brush to clean the tube externally

(b) A wire brush of appropriate diameter for cleaning the bonding fittings internally; failing that, a cylindrical piece of wood can be lined with fine sandpaper.

(c) A torch or other similar device producing a concentrated flame

d) A good flux for tin, free of harmful components, and a small brush to spread the flux

e) A weld roll must have the following characteristics: 95:5 welding

f) A thick cloth for the final cleaning of the weld

Additional considerations

* If the welding will be done on a pipe already installed and behind it there is a combustible material, for example, wood, use a metal plate or other similar device between the pipe and the wood in order to avoid fire

* When the pipe is already installed, welding should be carried out with nitrogen stream, as indicated by the technical standard

* Delimit the work area and have a container with water or a fire extinguisher in case of contingency

* Do not overheat the joint; This causes the silver and copper to rust, and the solder will be defective.

* If you work "on the head", protect yourself from possible drops of molten silver that may fall, especially the eyes

* Never touch the weld and its surrounding areas, until you are sure it is cold.

* Avoid cooling the welds with water as they contaminate the pipes and accessories.

* Jimy Danelli is a maintenance consultant in air conditioning and refrigeration. You can write to the email: [email protected]

* Jimy Danelli is a maintenance consultant in air conditioning and refrigeration. You can write to the email: [email protected]