In the second part of this three-part special, we will talk about the importance of reducing CO2 emissions.

by Eng. Arcadio Velásquez*

In the first installment, we learned about the relationship between factors related to global warming and the emission of carbon dioxide (CO2), as basic concepts and information in general - I have also shared relevant information about greenhouse gases and their harmful potential.

In this second installment, we will study in detail the amount of CO2 emitted by a cooling system, the rate of CO2 emissions per year, the heat gain, and the equivalence of trees to be planted to achieve the same reduction in CO2 emissions. In fact, we will study in detail how insulation helps reduce CO2 emissions.

First, we designed the system, a real-life case however for the purposes of this article is just an example: a common cooling system consists of a 2" NPS carbon steel pipe, 10m in length, with chilled water flowing at 10°C, the pipe is outdoors (outdoor) where the ambient temperature is 35°C. The system operates an average of 3,840 hours per year under these conditions.

Second, we calculate the heat gain (density of the heat flow rate): in this example, we will use two thermal insulation materials separately just for comparison, a polyolefin and an elastomer – it will be protected with a shiny aluminum jacket. Here are the results.

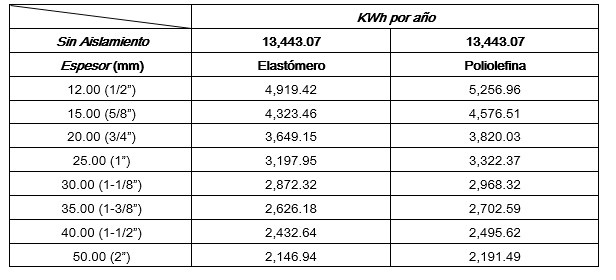

Table no.1 – Comparison of the annual heat gain between polyolefin and elastomer considering different thicknesses. Calculations made according to ISO 12241 with the help of Aero-Calc.

Table no.1 shows the total heat gained by the system within a specific time period, the heat gain rate will be added to the thermal load, creating a need for electrical consumption for the cooling equipment. The heat transfer rate density is typically used to determine the amount of work (energy) required to calculate the cost of electricity, the amount of fuel, and the emission of carbon dioxide.

Now, we will compare the CO2 reduction using table no.1 against the number of mature trees we need to plant to achieve the same reduction.

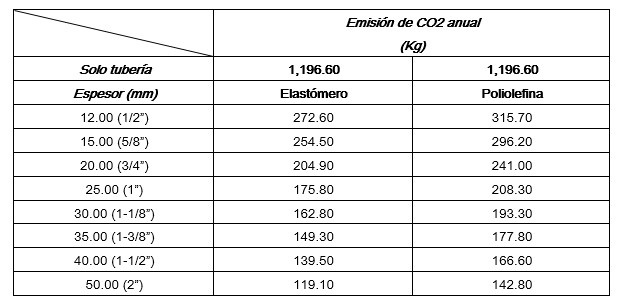

Table no.2 – CO2 emission per year considering 10m long pipeline and 3,840 hours of annual operation.

CO2 emission rates have been calculated with the help of 3E Plus® V4.1 (download link shared in part I) is a program for thermal calculations designed by NAIMA (North America Insulation Manufacturers Association). The values represent the total amount of CO2 emissions when the same cooling system operates 3,840 hours per year.

To understand the results, if the cooling system uses a 12mm (1/2") thick elastomer then 272.60 Kg of CO2 will be emitted instead of 1,196.60 Kg, which means a reduction of 77% annual emissions. If the same system uses the same material, but with a thickness of 50mm (2") then 119.10 Kg of CO2 will be emitted, which means a reduction of 90% annual emissions.

So, 50mm (2") thickness is the best choice? Not necessarily.

How to select the right thermal insulation material?

Two of the main reasons we use thermal insulation in cooling systems are to prevent condensation and reduce the rate of heat flux density. Thermal insulators reduce heat loss or gain inside or outside the duct, tank or pipe system, resulting in energy savings and operating costs. Thermo-insulated systems reduce the risk of condensation also to decrease microbial growth and other moisture-related damage.

What should we consider?

The Material

Some of the environmental benefits of insulation are obvious. In the HVAC&R industry, insulation reduces energy use, which in turn reduces pollution. But while all types of insulation generally reduce energy consumption, some can affect the environment differently: impact of insulation production, performance of recycled content, and recyclability.

There are many factors to consider when specifying or selecting the right thermal insulation material; In fact, this is not an easy task, but as engineers, manufacturers or consumers, we all have the right to decide what is best to save costs and what is best to save the planet and provide a healthy environment for future generations.

Return on Investment

One of the considerations is the ratio between the cost of insulation, including materials, installation and the cost of energy, these help us determine the forecast of what is known as "simple recovery period". The simple payback period does not take into account the time value of the money and is determined by counting the number of years it takes to recover the invested funds. For example, if it takes five years to recoup the cost of an investment, the payback period is five years.

Cost of electric power

Standards such as ASHRAE 90.1 and BS 5422 contain requirements for insulation thicknesses of pipes and ducts developed on the basis of technical and economic principles. These requirements were determined with computer simulations of the annual energy flow through insulation, the first cost projections for insulation, the economic projections of discount rate and energy escalation rate. In previous years, the same tools were used to analyze the sensitivity of the cost-effective insulation level for pipe insulation to variations in operating hours, ambient temperature, fluid temperature, and economic projections.

The cost of energy is different in all cases, it depends on the energy source, the location, it depends on local regulations, stations, systems and, of course, the constant use of isolated systems. The cost of energy is related to the amount of money paid in a specific time period (tariff) and the savings given by thermal insulation. For this, it is relevant to know the cost of the energy cycle and the number of hours in which the system is operating to forecast the total cost of the energy used for the calculation of the simple recovery period.

Economical thickness

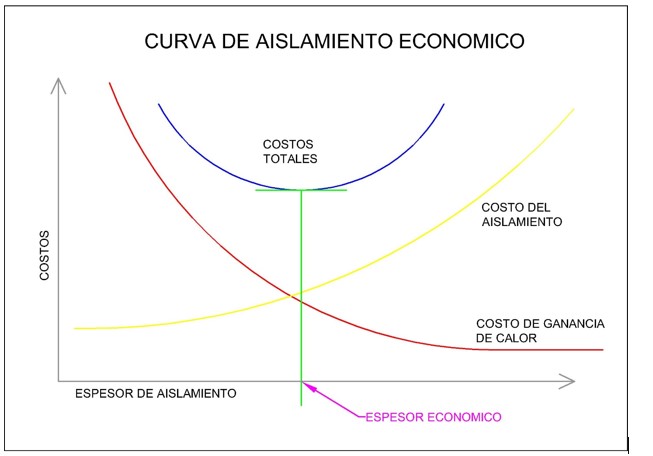

When we talk about economic thickness, we do not refer to the minimum thickness that could work in a system, we refer to the thickness of thermal insulation applied to a system that guarantees the highest profitability in a known period. According to BS 5422, the thickness of an insulation system is determined by the optimal cost structure, with the lowest total annual costs. The three main cost components in this cost structure are:

The cost of the proper insulation system, capital cost.

The cost of maintaining the installed insulation system.

The cost of heat loss/gain through the insulation system.

The total costs for a specific insulation thickness are the sum of the costs named above, under similar conditions. Therefore, insulation system costs should be determined per year based on the investment cost multiplied by an escalation factor, in combination with maintenance costs. These annual costs are compared to the annual cost of energy loss.

Figure nº 1 – Economic thickness curve

Once all the parameters mentioned above are known, we will be able to select which is the thermal insulation material that best suits us to satisfy with the best profitability in terms of initial investment, maintenance, return on investment, and most importantly,

the most sustainable.

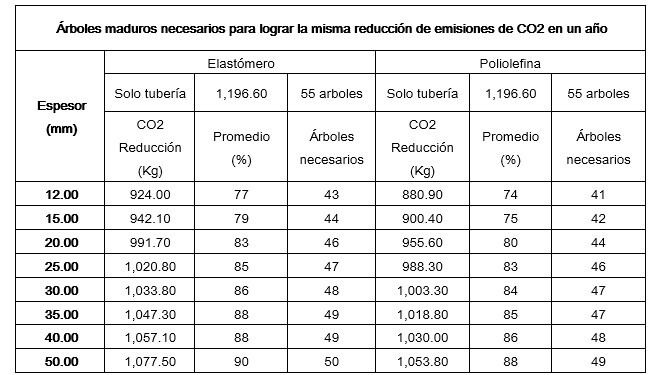

In that case, we will use the example mentioned above to determine how many mature trees we will need to achieve the same carbon dioxide reduction that a thermal insulator provides. Whereas a mature tree can absorb between 20 and 22 kg of carbon dioxide annually:

Table no. 3– Trees needed to absorb carbon dioxide.

Table no. 3 shows CO2 reduction using a polyolefin and an elastomer. For example, the 12mm (1/2") thick elastomer reduces CO2 emissions from 1,196.6 kg to 924 kg per year, on average, 77% therefore 43 trees are required to absorb that amount, while the same thickness of polyolefin reduces the emission to 880.90 kg, on average, 74% or 41 trees.

Trees are an important part of the carbon cycle, as trees and all plants use photosynthesis to remove and store carbon from the atmosphere (while at the same time releasing oxygen).

Clearly, mechanical insulation is a considerably more effective means of reducing carbon emissions than planting trees; In fact, it is easier to prevent carbon emissions than to remove it from the atmosphere once released.

* Explanatory note: I must clarify that my goal is not to avoid planting trees, quite the opposite, despite the approach and comparison between carbon dioxide emission reduction provided by the use of thermal insulation in HVAC&R systems and the equivalence of trees that absorb the same amount of carbon dioxide – as I mentioned earlier, The results are incredible – we should always encourage tree planting and forest preservation.

* Written by: Arcadio J. Velásquez | Mechanical Engineer.

Mr. Technical Marketing Engineer – Hira Industries LLC.

Thermal Insulation Specialist

Dubai, United Arab Emirates.