Using Johnson Controls' Facility Explorer platform and its versatility in programming development, this project was successfully completed in Costa Rica.

by Johnson Controls

Considered as the revolution in vertical markets in Central America, Oxygen Human Playground is one of the most important shopping complexes in Costa Rica. With more than 200,000 square meters of construction it gives its visitors a different concept with 5 "worlds": Live, breathe, feel, be and explore. Each of them suitable to offer an unparalleled experience to its visitors.

It is made up of spaces designed for the development of "indoor" events such as concerts, theatrical performances; spaces for the development of indoor and outdoor sports activities, a gym of 1500m2, swimming pool, surfing in artificial waves, climbing wall and "canopy", are some of the multiple activities that can be done in this large complex. More than 200 commercial premises with the most recognized brands in the fashion market; and a space exclusively designed for the little ones.

The design and realization of this project was executed in conjunction with the ISA Automated Services Integration specialists, such as ABCS (Authorized Specialist for Building Control, its acronym in English) of Johnson Controls in Costa Rica.

One of the objectives established by the client was the reduction of the environmental impact through the use of renewable energies, such as the use of rainwater and a control system that will optimize the use of energy in the most demanded systems: Air conditioning, lighting, UPS, generators and substations, escalators and elevators, among other systems.

In the face of great challenges, intelligent solutions

Undoubtedly, during the development of this project one of the biggest challenges was the limited time for the execution process, taking into account the number of devices and systems to be integrated.

However, thanks to the features of johnson Controls' Facility Explorer platform and its versatility in programming development, this project was successfully accomplished, making each of the systems work at its optimum point of efficiency.

Johnson Controls' Facility Explorer control platform was the ideal solution, thanks to its ability to integrate into different types of communication protocols, which were key to developing the centralization system that the client required.

The solution was thought in an integral way for the 5 buildings that constitute this great complex, the number of systems to be integrated and the monitoring resources that the client established in his requirement.

Results that decrease costs and increase benefits

The centralization system has an FX-Server installed on the client's server with a capacity of 4TB and an Octacore processor of 16GB in RAM, with a Niagara license with integration capacity of more than 5000 IP points and SQL databases, managing to offer the client a customized BMS.

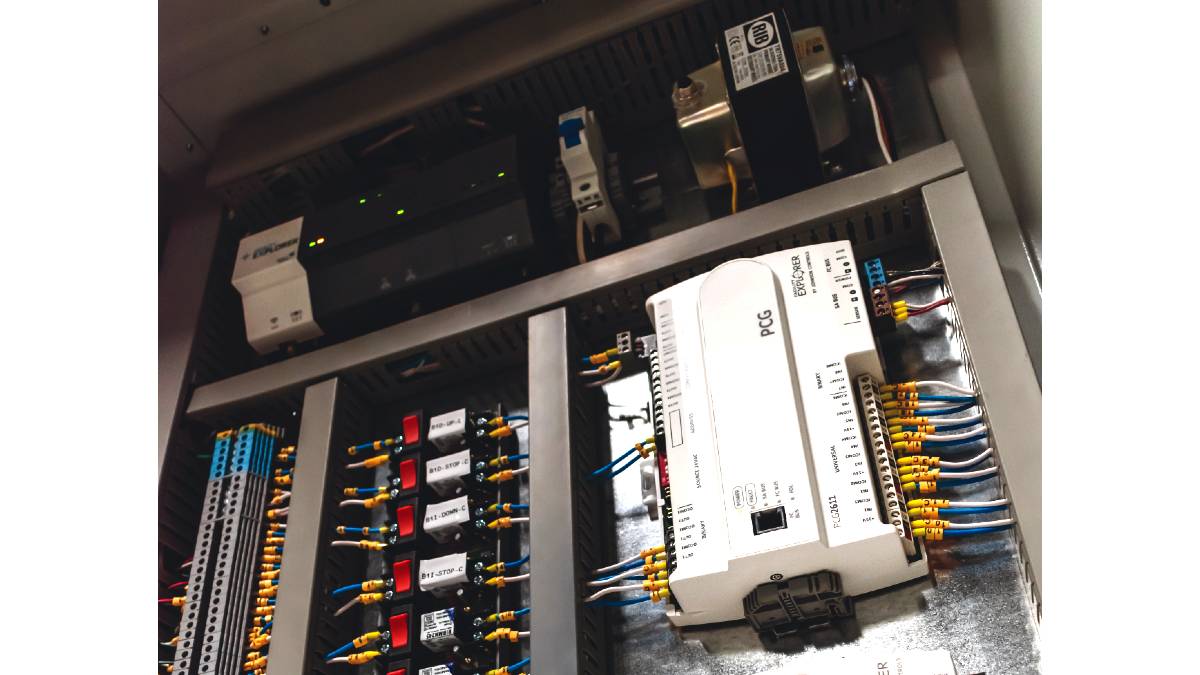

This server has an Ethernet connection of 10 FX80 supervisors that brings together all the variables collected in each of the buildings and each of the dedicated field controllers.

While at the field level more than 35 FX-PCG programmable controllers were installed with FX-PCX expansions located on their respective control boards and assembled with the best quality standards. Each of these controllers include the ideal operation sequence for the optimal operation of each system, using the dedicated and improved Johnson Controls programming resources for application in HVAC systems, likewise, the use of functions such as PRAC + Adaptive Tuning, improve the response times of the controllers after the operation of the systems, generating predictive behavior on the connected system and increasing the useful life of the equipment while decreasing energy use.

To these boards distributed throughout the complex, signals from sensors located in the field arrive; temperature, pressure, current sensors, contacts of electrical panels and in turn start equipment start commands.

The scope of this project included the measurement of the ice water consumption of each tenant for their respective use in their local air conditioning system, also the measurement of drinking water consumption for those who required it, which at the control level demanded the need to include meters in order to develop a billing system in the same Facility Explorer centralization platform.

This system could download month after month the consumption of each tenant in a stable and secure way, allowing them to make a reliable collection and with real data.

With this control, the client was given a complete supervision system, where he can perform permanent monitoring of the variables of the systems, in addition each operator can perform traceability of the equipment and have real-time information of unusual behaviors that allow the intervention of equipment in a timely manner; in the same way, the information obtained by each system allows maintenance processes to be carried out to each of the integrated systems in an intelligent way, saving costs in the operation of the building.

The systems controlled and integrated through the Facility Explorer platform were:

• 15 drinking water pumps and their recirculation system

• 44 escalators of the complex

• Ice water plant

• Lighting system

Other systems integrated through the Facility Explorer platform are the following:

• 8 sewage pumps via Modbus TCP protocol direct connection without additional hardware to the FX80 supervisor

• 15 elevators

• 6 integrated generators via Modbus RTU

• Pressurized dome via MODbus TCP

• Integration, control and monitoring of control valves and BTUH consumption measurement for commercial premises of a third-way brand BACnet MS/TP

• Monitoring of 164 drinking water meters

• Monitoring of 7 electrical substations

• Monitoring of the wastewater treatment plant