An ideal solution for the current times and ventilation needs in the different verticals.

by Eng. José Arboledas*

The ventilation needs of the premises occupied with human presence are included in all existing Regulations and Regulations. It is not an isolated case of RITE, Regulation of Thermal Installations in Buildings for Spain or ASHRAE, American Society Of Heating, Refrigerating And A-C Engineers. Following the emergence of SARS-CoV-2, the tightening of these Rules and Regulations and the emergence of new standards are expected.

The problem arises when we detect that the thermal loads associated with this ventilation are high, in fact, the EcoDesign Regulation (Regulation 1253/2014 of the European Commission) establishes that the recuperators must have high efficiencies, 73% for fixed ones and 68% for rotary ones.

This Regulation 1253 has been one of the most significant changes in the new RITE 2021 (Regulation of Thermal Installations in Buildings for Spain) that entered into force on July 1 of this year and that has raised this efficiency from the lowest level previously contemplated from 44% to 73% cited. Even so, the costs are high and we must try to minimize, in addition, what happens when this Regulation has not been complied with and now a previously unventilated room must be ventilated? Should the entire facility be remodeled? The answer at the end of the article.

Energy costs

In conversations held in the world of air conditioning, the energy costs of ventilation loads in premises have rarely been evaluated, they are taken as one more load and acted as indicated by the Regulations, recuperators are installed and the power of the equipment is adapted to it.

Let's look at a couple of examples:

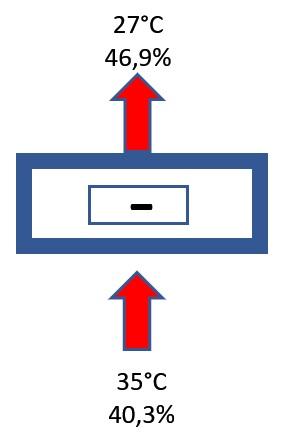

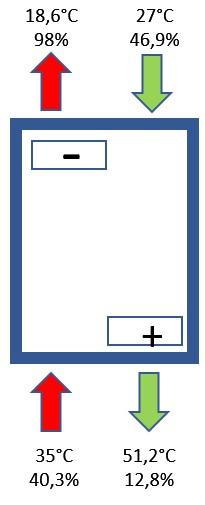

If we want to ventilate with neutral air, air with return conditions, a room with design conditions 27°C/46.9HR% with an outside air at 35°C/40.3HR%, we will need 5.98 kW for every 1,000m³/h. If we consider an EER of 2.8 (kW/kW), the energy consumption is 2.13 kW electric.

Figure 1.

With RITE Regulation (Regulation of Thermal Installations in Buildings for Spain) this is equivalent to:

• IDA 3 or medium quality air: 34 people in a shop

• IDA 2 or good quality air: 22 people in a classroom

• IDA 1 or air of optimal quality: 13 people a clinic

These data are very similar to those of ASHRAE (American Society Of Heating, Refrigerating And A-C Engineers), since, if it requires less ventilation rate per person, if it also ventilates the space, something that RITE (Regulation of Thermal Installations in Buildings for Spain) does not contemplate. Of course, these occupations are usually higher and the necessary powers multiples of it.

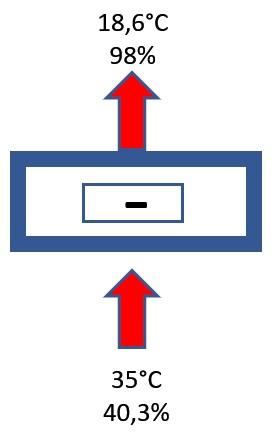

The case is aggravated when we want to insert air already air-conditioned, in this case the injection of air at 18°C/98HR% implies a power of 6.55 kW refrigerators. If we consider an EER of 2.8 (kW/kW), the energy consumption is 2.34 kW electric.

Figure 2.

Obviously these numbers should be avoided and no designer in their right mind would advise this solution, which in case you have not noticed, is outside of any Regulation.

Passive recovery

We all know passive recovery, air flows that yield residual energies from the exhaust air, even in good thermal conditions, to pre-adapt the ventilation outside air to the indoor conditions and minimize the power of the air conditioning equipment. Exchanges can be only thermal, plate exchangers, or thermo-hygrometric, rotary exchangers that yield energy and moisture.

The latter are being separated by the recirculation between the expulsion of air and the injection of air, returned air that by SARS-CoV-2 is no longer desired. We assume that new equipment of this type will contemplate this problem and solve it.

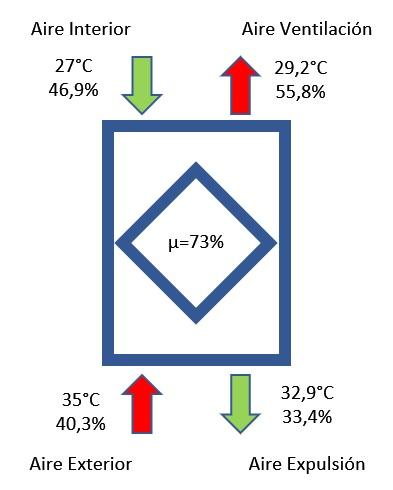

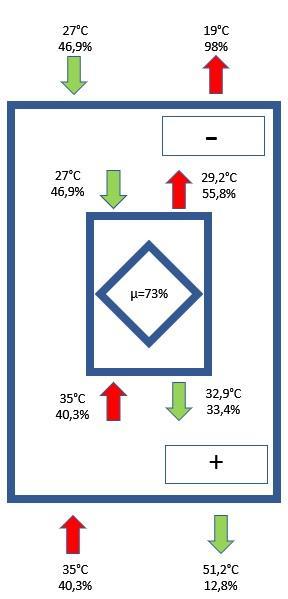

Figure 3.

For the case at hand, a cross-flow recuperator with 73% efficiency would give us ventilation air in the following conditions.

The air supplied would be a little high to consider neutral air but valid to see how the equipment works.

In this case the power to leave the air provided by the recuperator in neutral air conditions would be 3.96 kW for each 1,000m³/h. If we consider an EER of 2.8 (kW/kW), the energy consumption is 1.41 kW electric. (Remember this consumption data, we will take it as a reference in the final comparison).

Figure 4.

Curious, it does not save 73% of the necessary power, only 33%. Logical, we are only working on the sensitive part of the power, the latent power remains intact and in the global has a high weight. This is another aspect rarely contemplated, the absolute humidity of the air, the confusion between absolute and relative humidity, that an air with lower relative humidity contains less water in it. It is a widespread error, the relative humidity is relative and depends on the dry temperature of the air.

Active recovery

The concept that may not be so well known is that of active recovery, cold recovery also called. This technology is based on the multiplication of the energy of the indoor air that will be expelled when passing through the condensing battery of the refrigeration circuit that heats the outdoor ventilation air. Although it looks like a tongue twister, the graph below explains it clearly.

Figure 5.

Let's take a compact air-to-air equipment and join its condensation and evaporation air loops, but carefully.

The indoor air to be expelled is in very good thermal condition (27°C/46.9%RH) and is passed through the condenser of the refrigeration circuit. The air from the outside, which we want to transform into air-conditioned ventilation air, is passed through the evaporator and the result is a cooling power of 6.55 kW, as in the case of the recovery combination plus previous cold battery, but with an EER of 4.4 (kW / kW), an energy consumption of 1.49 kW. In this case what is avoided is the installation of the recuperator.

Active recovery really works. What would happen if we combined both technologies?

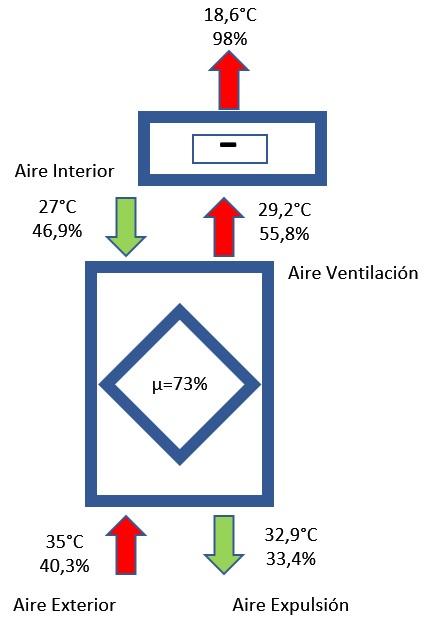

Active-passive recovery

The union of both technologies would create this type of compact equipment of very easy installation, no extra conduit of the normal ones of a climate equipment, single housing, a single installation, all are virtues.

Again we take a compact equipment and, carefully, we make the interior air to be expelled pass through the recuperator and the condenser. The outside air for air conditioning is tempered in the recuperator and passed later through the evaporator. This combination brings together two recovery technologies, passive and active.

Figure 6.

The power that the refrigeration circuit should provide would be calculated 3.98 kW, but with a consumption of 0.90 kW. A saving of 36% in the consumption of the ActivoPasivo equipment.

Now we can say that the conjunction of active and passive recovery is the solution to the ventilation of premises.

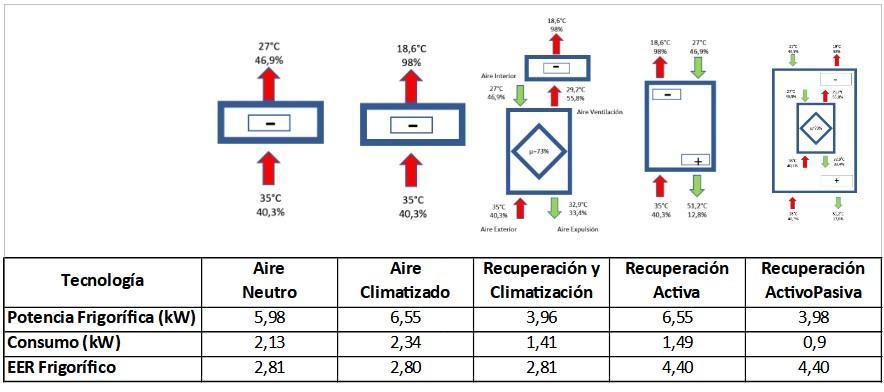

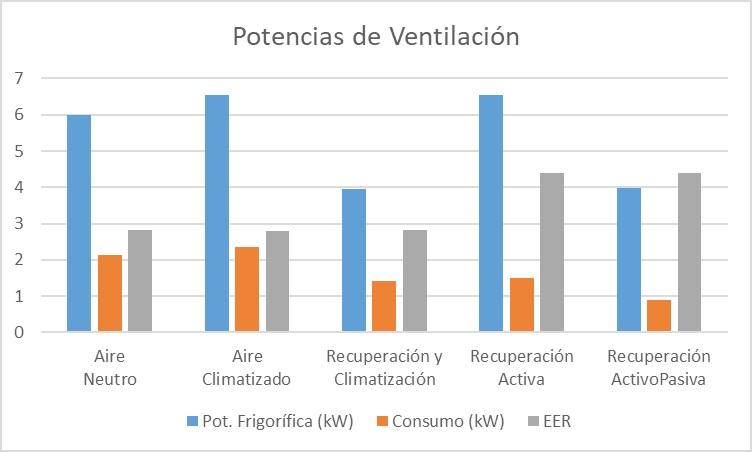

Let's make history: If we tabulate the results of the energy consumption of the different technologies, we can see:

Figure 7.

Figure 8.

As can be seen, the answer to the question on how to insert in Regulation the premises not adhered to it is simple. This equipment does not interfere with the existing installation, a new heat recuperator introduces thermal loads that the initial installation did not contemplate, so we find subpotent installations, new air conditioning equipment would be needed to compensate for this ventilation.

The choice lies in whether we want to introduce neutral or air-conditioned air, perhaps the existing installation fell short. The answer from the point of view of an expert in air conditioning and ventilation is that the air must be inserted air-conditioned.

For both cases the solution is completely valid and only requires an electrical connection, there are no outdoor units or pipe runs, only power supply and a strategic place to locate it.

*Eng. José Arboledas, Head of Training and Special Projects at Keyter - [email protected]

*Eng. José Arboledas, Head of Training and Special Projects at Keyter - [email protected]