Technical recommendations to comply with an adequate installation of an air conditioning system in an area of high risk of fire or explosion.

Technical recommendations to comply with an adequate installation of an air conditioning system in an area of high risk of fire or explosion.

by Ernesto Sanguinetti Remusgo*

We have always heard that air conditioning equipment and /or engines that are used in environments that have industrial processes within the field of oil, petrochemical, explosives manufacturing and the like must be "explosion proof"; having a high probability of occurrence of fires and explosions, due to the nature of combustible and flammable liquids/gases that are permanently handled.

Therefore, it is necessary to eliminate all ignition sources that can ignite such fuels and their mixtures. To do this, the area classified as hazardous (potentially explosive atmosphere) must be identified, in order to use the appropriate electrical equipment and accessories in that area.

In this context, the standards of each country, complemented by international standards, should establish the necessary measures to ensure that activities in such establishments are carried out safely in order to preserve the life, health and safety of the workers of the establishments, visitors and the general public.

Definitions

Hazardous Area: This is the enclosure or area where a hazardous atmosphere exists or may exist.

Hazardous atmosphere: It is one that contains a significant amount of vapors or flammable gases, in concentrations capable of producing ignition or that are toxic concentrations.

Anti-explosive electrical installation: It will be understood as an anti-explosive electrical installation to which when there are flammable vapors inside and outside any part of it, it behaves in such a way that the inflammation of the interior vapors or any failure of the installation or the equipment, does not cause the inflammation of the vapors existing outside.

Explosion-proof apparatus: Apparatus enclosed in a box that is capable of resisting ignition or an explosion of a specific gas/steam that may occur within it and of preventing the ignition of a specific gas or steam surrounding the envelope by sparks, flashes, or explosion of the gas/steam within it. It must be able to operate at such an external temperature that a surrounding flammable atmosphere will not ignite because of it.

Ventilation: Ventilation can be achieved by introducing fresh air to dilute polluted air or by local extraction of polluted air. Ventilation is considered adequate if it is sufficient to prevent the accumulation of significant amounts of air-vapour mixtures in concentrations greater than one quarter of the Lower Flammability Limit (25% LII).

Explosive limits: For an explosive atmosphere to form, the concentration of flammable gases, vapours or mists in air must be within a certain range, delimited by the lower and upper explosive limits:

- Lower Explosive Limit (LIE): It is the minimum concentration of flammable gases, vapors or mists in air below which the mixture is not explosive. It is also known as the Lower Flammability Limit (LII)

- Upper Explosive Limit (LSE): It is the maximum concentration of flammable gases, vapors or mists in air above which the mixture is not explosive. These limits are usually expressed in percentages of the volume of the gas or steam in the volume of the mixture.

If a given mixture of flammable gases or vapours in air is not to produce an explosive atmosphere, the concentration of flammable gases or vapours in air must be maintained either below the LIE or above the LSE. The first option is usually taken, with adequate means of ventilation or extraction, for the exterior of the equipment (offices, laboratories, pump or compressor rooms, paint booths, drying tunnels, etc.).

The second option is usually used inside the equipment (case of tank or tank, reactors, pipes, etc.) either because the vapors or flammable gases occupy most or all of the volume of the equipment or because the air is displaced with an inert gas.

Undoubtedly, not only the air conditioning equipment must comply with the requirements demanded by the AREA but every machine, engine, instrument, tool that exists within it to have reliability in the works and processes that are carried out, eliminating the possibility of producing fires and explosions, providing safety. To acquire an air conditioning equipment, a machine, instrument or tool in this type of application, the main aspects of the process and the characteristics of the areas involved must be known.

In the case of manufacturers of "explosion-proof" air conditioning equipment, in order to supply them, they will ask for the correct classification of the area where they will be installed because they are specially manufactured equipment and to order. Let's explain how the classification is done:

Classification

Due to the diversity of processes, the areas can be of different types where there are usually atmospheres with a diversity of flammable gases or vapors, being therefore very necessary to define the classification of them.

The most common classification systems for hazardous locations are the national Electrical Code (CEN) divisional classification system that must exist in each country; which are mainly based on and complemented by the zoning system used by the European Union (EU) and the International Electrotechnical Commission (IEC or IEC).

To classify the areas the following criteria are used: - Determine the Class of the area where the nature of the product that escapes into the atmosphere is taken into account. - determine the division of the area where the extent and frequency of the flammable substances or mixtures to be present is taken into account. -Determine the Group of the area where the chemical properties of the substance released into the atmosphere are taken into account, which determine how easily it tends to burn or explode.

How Areas are classified

The classification of Areas is a method of analysis applied to the environment where flammable and/or explosive vapors, gases, fibers or dusts may exist; in order to establish the precautionary measures to be considered in the construction, selection, installation, handling and use of electrical materials and equipment to eliminate or minimize the presence of ignition sources.

A.-Classification by Class

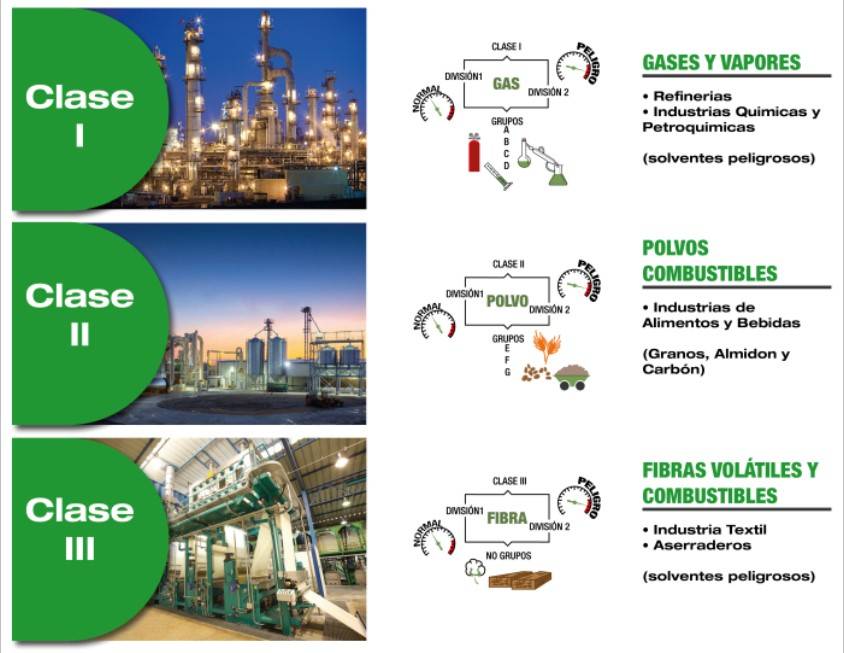

Class I: Those places where there may be gases or vapors in sufficient quantity to produce flammable mixtures are considered. Class I hazardous areas are sub-divided into Zones according to the occurrence and dwell time of the explosive atmosphere.

So we have: - Class I - Zone 0: Zone 0 is called the area in which an explosive atmosphere is present in long periods of time or continuously. - Class I – Zone 1: Zone 1 is the one in which an explosive atmosphere is likely to exist in normal operation work. - Class I – Zone 2: Zone 2 is called the area that has a very low probability of an explosive atmosphere occurring in normal operation work and if it occurred, it would only occur for a short time.

Class II: Those places where coal, products with carbon components and flammable organic powders are present are considered.

Class III: Those places where flammable fibrous materials are present are considered.

B.-classification by Division

The classification by Division takes into account the frequency of leaks or leaks and the level of ventilation of the area to be considered, in order to establish the level of risk present in that environment. 2 divisions are considered:

Division 1: Here are considered those areas where under normal working conditions or due to frequent repair and maintenance work, there are leaks of vapors or gases that have flammable concentrations. Also considered are those areas where it is expected that due to a rupture of pipes or abnormal operation of equipment that performs the processes, they can produce leaks of vapors or gases in flammable concentrations and that at the same time may occur failure in the electrical equipment or electrical system.

Division 2: In this division are considered those areas where flammable products are stored, processed or handled, but in which there are normally no dangerous concentrations because the products are stored in containers or closed circuits from which they can only escape in case of breakage, abnormal operation of process equipment. Also considered are areas where flammable concentrations of vapors or gases are unlikely because positive ventilation systems are in place and therefore only failures of such systems may result in the presence of a flammable atmosphere, contiguous to Class I, Division 1 areas to which flammable concentrations of vapors or gases may occasionally arrive, unless such communication is prevented by adequate ventilation systems and devices are in place to prevent the failure of those systems. As a consequence, areas where the described conditions are met are classified as Division 2.

C.-Classification by Group

The classification by Group takes into account the explosive characteristics of vapours and gases or mixtures of vapours or gases, varying with the type of material involved. Substances in a given group present risks of similar characteristics. Class I is divided into groups A, B, C and D depending on the maximum explosion intensity and minimum ignition temperature of the substance or mixture. Also considered as another important factor, the ease of attenuation of the explosion of that substance or mixture in an enclosed space, so that it does not affect to produce explosion in any surrounding flammable mixture. We give below a table with substances that may be present in the atmosphere of the environment to be conditioned, which are classified or labeled according to their class and corresponding group:

Class 1 (gases and vapours)

Group A: Acetylene. Group B: Hydrogen, butadiene, ethylene oxide, among others. Group C: Ethylene, ether, diethyl ether, acetaldehyde, among others. Group D: Gasoline, propane, butane, methane, acetone, ammonia, natural gas, among others.

Class 2 (combustible powders)

GROUP E: Metal powders such as aluminum, magnesium. GROUP F: Coal, coke and other similar powders. Group G: Flours, starches, wood powders, grain powders, plastics and chemicals.

Class 3 (fibres)

Natural fibres, synthetic fibres

Figure 1.

Note: In the second part of this article we will look at some examples of classification of hazardous areas and how to request and specify an air conditioner for this type of hazardous environments.

* Mr. Ernesto Sanguinetti Remusgo, Manager of the Engineering Division - Cold Import S.A. - Lima - Peru.