Below we will see how CFD simulations allow us to identify the selection of suitable textile ductile designs according to the needs.

by Textile Diffusion

Below we will see how CFD simulations allow us to identify the selection of suitable textile ductile designs according to the needs.

by Textile Diffusion

Throughout the history of humanity and in particular the activities of the field of air conditioning, change and innovation have always been presented as a reaction to problems, but will it be possible to prevent the exhaustive, costly and risky process of empiricism in order to find specific solutions to complex problems?

The current design methodology is based on the need to propose accurate solutions, but unlike other disciplines, within our projects experimentation is unfeasible, although much progress has been made through experience and deduction to build theories, these methodologies do not cease to be naïve since before the premise that every project presents particular and own conditions, the generality of the theory reveals that the rigidity of its process is an irrefutable defect; when applying the general over the particular, this gives rise to exceptions, irregularities, defects and unforeseen events that can certainly be said that most projects are presented and that they consume time and resources.

Today's challenges center around energy efficiency, minimizing the cost of operations, and people's safety and hygiene. Faced with these challenges, making use of technological means, the answer to the problems of the real world could be found in the virtual world.

It is in this framework where the terms pre-engineering, validation, verification and verification make sense, more and more companies within the field stand out by being able to use computational simulations in fluid dynamics (CFD) to understand the impact of their designs and decisions while justifying their projects and guaranteeing the operation of their proposals following the pattern of efficiency, efficacy and safety.

Here are some cases where simulation demonstrated feasibility and perfected the design:

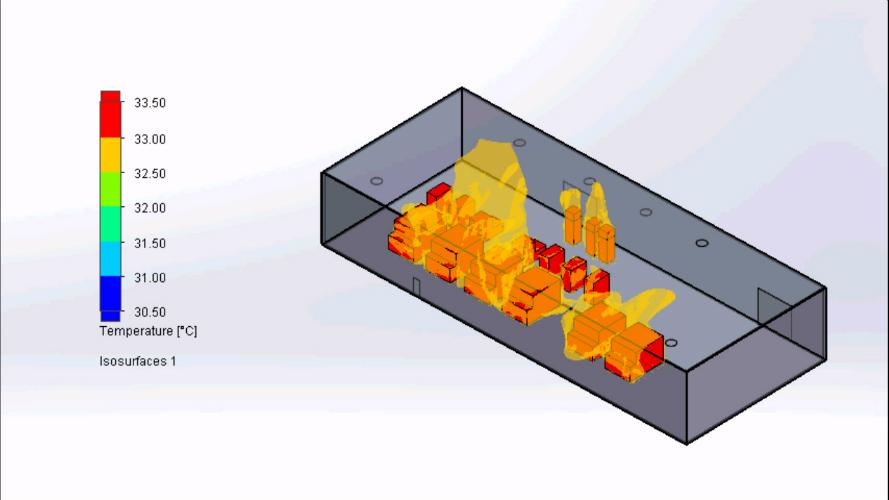

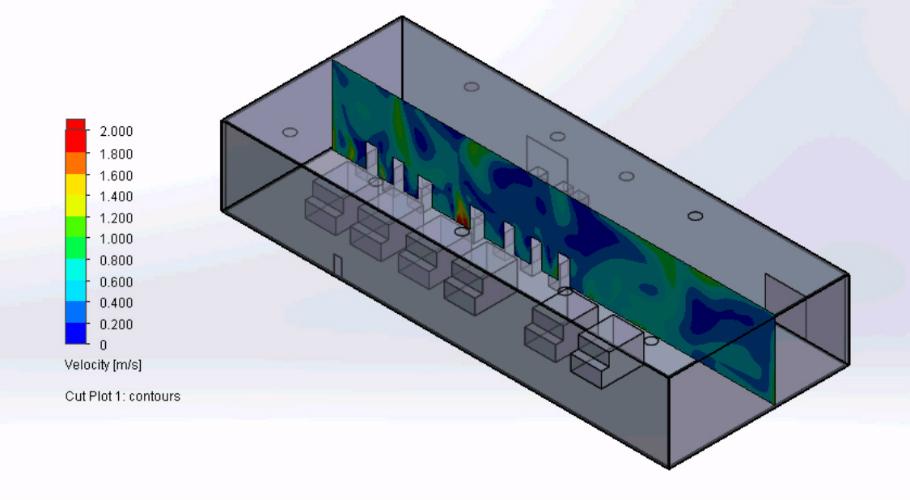

Case 1

Developer: MCAT

Project: Industrial Plant

Location: Guanajuato, Mexico

Software: SolidWorks Flow Simulation 2013

Background of the project: There is a work area with the presence of furnaces, which concentrate heat outside the thermal tolerance range, a ventilation system has been proposed that injects air from the outside as well as an extraction system to take the hot air from the space. Likewise, it is required that the air velocity inside the space is moderate so as not to run the risk of extinguishing the flames of the burners and thus know the temperatures that will occur on the site once the system is installed.

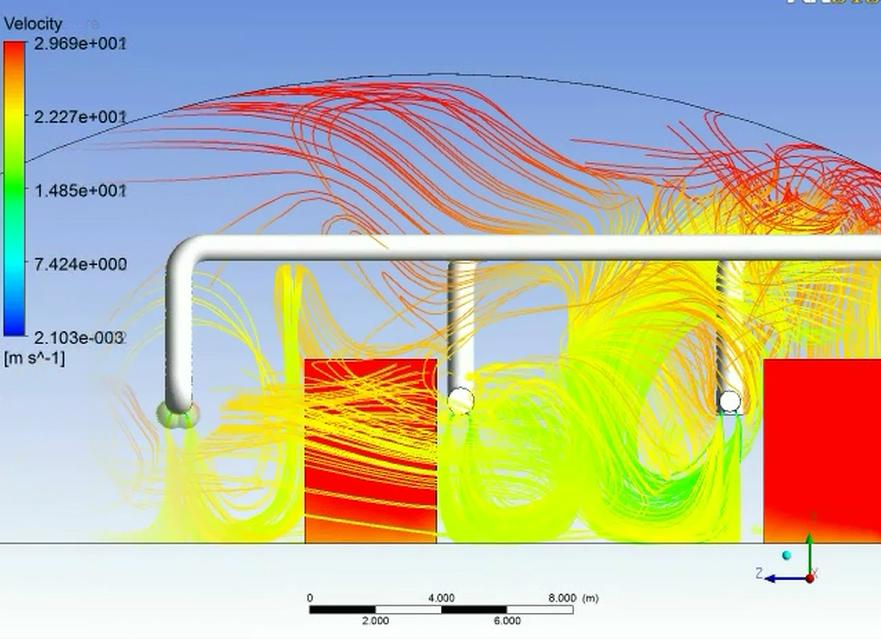

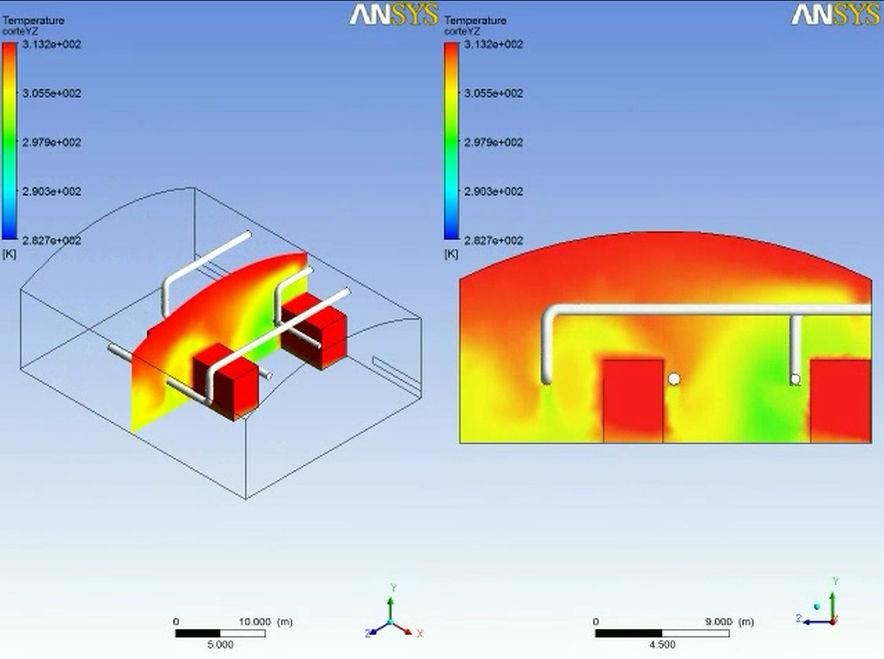

Case 2

Developer: Thermoservices and maintenance

Project: Automotive plant

Location: Colombia

Software: ANSYS 14.0

Background of the project: In the presence of process machines with high temperatures, it was necessary to find a solution that would break the heat spread and allow thermal tolerance zones for the system operators. Through the CFD simulation it was shown that the most viable option was a textile ducting system with a linear multiflow air injection, which allows generating the conditions of an air curtain preventing heat from interfering with the activities of the area.

Case 3

Background of the project: In the presence of process machines with high temperatures, it was necessary to find a solution that would break the heat spread and allow thermal tolerance zones for the system operators. Through the CFD simulation it was shown that the most viable option was a textile ducting system with a linear multiflow air injection, which allows generating the conditions of an air curtain preventing heat from interfering with the activities of the area.

Case 3

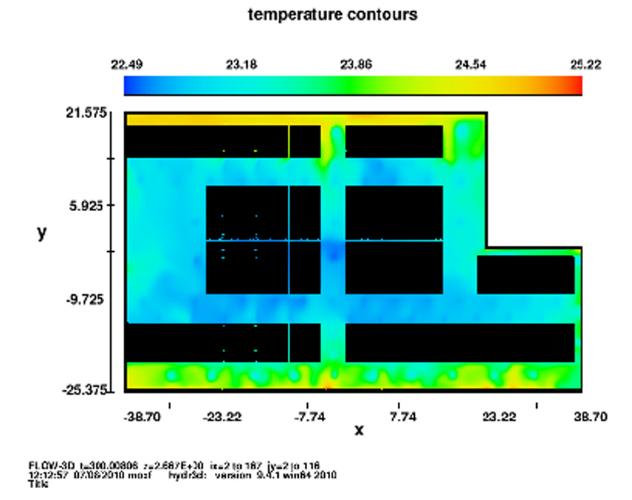

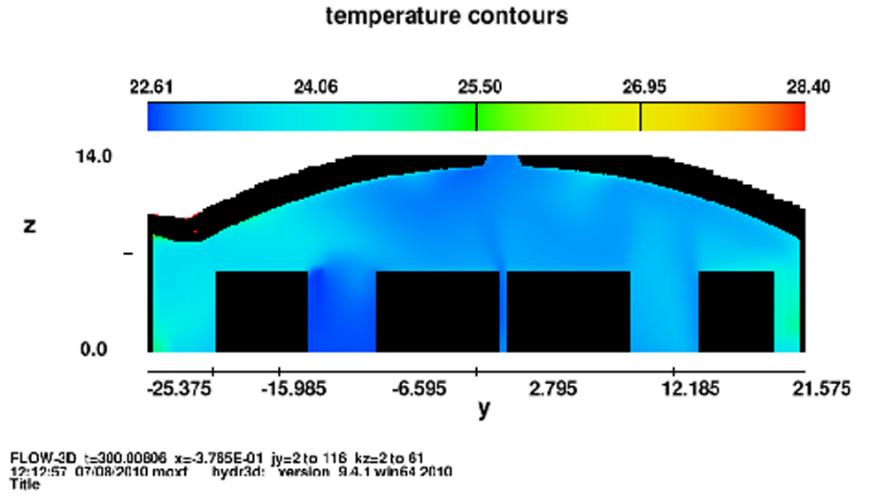

Developer: Natural Cooling

Project: Perishable food warehouse

Location: Colombia

Software: Flow 3D

Background of the project: Given the need to find sustainable solutions that in turn are profitable, a system was designed for this warehouse that is at the same time efficient, sustainable and much more profitable. This system is made up of a Canadian posos installation to cool the air and a network of ducts with textile diffusion, since it had to comply with a constant temperature 24 hours a day, and 365 days a year. Given the sensitivity of storing food products, the certainty that an unconventional system was adequate was paramount, so through CFD simulation it was possible to guarantee that the client's investment and the selection of the system were successful.

"In theory, there is no difference between practice and theory. In practice, there is." Albert Einstein.

Background of the project: Given the need to find sustainable solutions that in turn are profitable, a system was designed for this warehouse that is at the same time efficient, sustainable and much more profitable. This system is made up of a Canadian posos installation to cool the air and a network of ducts with textile diffusion, since it had to comply with a constant temperature 24 hours a day, and 365 days a year. Given the sensitivity of storing food products, the certainty that an unconventional system was adequate was paramount, so through CFD simulation it was possible to guarantee that the client's investment and the selection of the system were successful.

"In theory, there is no difference between practice and theory. In practice, there is." Albert Einstein.