Myths and realities of this kind of systems implemented in commercial refrigeration in supermarkets and supermarkets.

by Giovanni Barletta*

Myths and realities of this kind of systems implemented in commercial refrigeration in supermarkets and supermarkets.

by Giovanni Barletta*

The refrigeration of supermarkets, and large supermarkets, also called "food cold", has always been the object of conceptualization on the ideal way of designing the architecture that involves the furniture, and the (or the) production centers of "cold". And all this happens, from different technologies, through many refrigerant options and a number of new and recent regulations.

From the traditional direct expansion systems, through the technologies of natural refrigerants, such as CO2, Ammonia, among others, and the recently called "loop loop" arrangements that use condensers of the water-cooled type, resembling more of a self-contained.

Traditionally, two architectures have been discussed: both with successful trajectories in many end users and markets and also differ from country to country, even competing according to trends between the West and Europe.

Conceptualization of the most common architectures

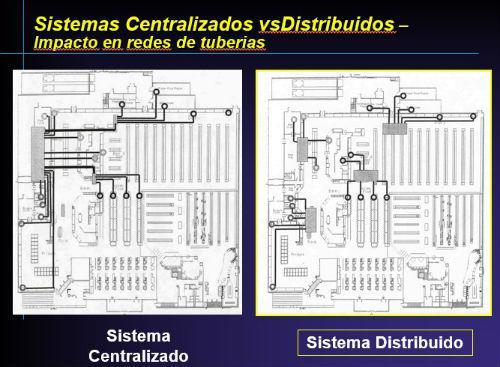

Typically the two most common and generalized options move between centralized systems and distributed systems and this connotation has impacts not only from the very location of the cold plant with respect to refrigerated furniture, but also with regard to copper pipe networks, control systems, wiring, labor and countless other factors that we will try to summarize in schemes and criteria that, although not universal, have validity in favor of one or the other.

We could say in some way that the centralized system is understood as the "traditional" system and we will try to show the most recent trend and migration towards an architecture that proposes control from the furniture, and "loop" type networks or also what this article enunciates as "distributed system".

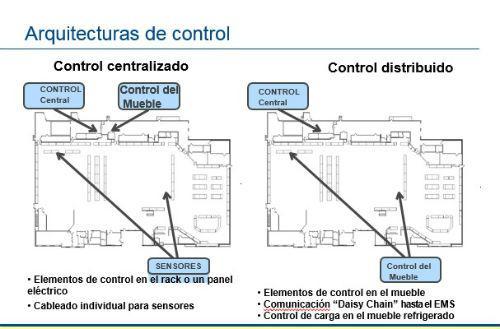

In the Centralized Systems we will find a cold plant full of elements: multiple copper pipes entering and leaving-from there they also call it "multicircuit" to this type of architecture, with solenoid in each branch, suction pressure regulating valves that comes pre-installed by the manufacturer, likewise all the control managed from an intelligent central and from there commands everything, only depending on analog input signals of sensors that come from the point of sale and from the furniture and refrigerated chambers, also all the wiring of force and control reaches the rack.

Numerous input and output cards to be able to command all these maneuvers which are on the board receiving and returning signals from the control.

The network of copper pipes at the point of sale becomes very extensive, since each line of exhibitors requires its own food. This extensive network of copper pipes is associated with a significant load of refrigerant, in its installation a qualified workforce, support costs, insulation and accessories. From the point of view of efficiency, there is also a penalty for pressure drops, due to the long travels and accessories that this demands.

In the Distributed Systems or control from the furniture, we find a network of pipes type "loop" also called in some markets as "fishbone", where very few branches come out from the rack and are subdivided to each piece of furniture or group. At the same time, a controller is located near them, autonomous and capable of acting on its own, only sending signals, interconnected with each other, to the central located in the rack. Figure 1 shows the different control schemes between the two architectures for the same store arrangement.

Figure 1. Differences in control systems for two types of architecture.

From the control point of view, the implementation and addition of control elements that allow better regulation, such as electronic expansion valves, and better de-icing system, condensation control, as summarized in Figure 2, is facilitated.

Simultaneously this type of scheme demands a smaller number of pipes and thus less amount of refrigerant charge

Figure 2. Components associated with distributed systems that improve control and regulation.

Given this, the question arises: What has generated this change in trends? Why migrate from a traditional system to new control architectures and pipeline lines?

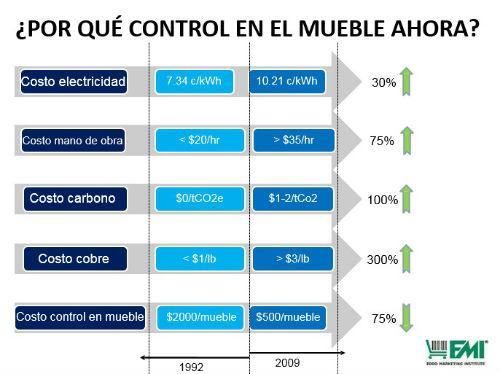

Figure 3 shows how the variables of energy, labor, the impact on the carbon footprint, and the unpredictable cost of copper in international markets have behaved over the past 20 years. To all the above is added that the costs of electronic controls of furniture due to the developments of electronic production systems have decreased considerably and make it more competitive.

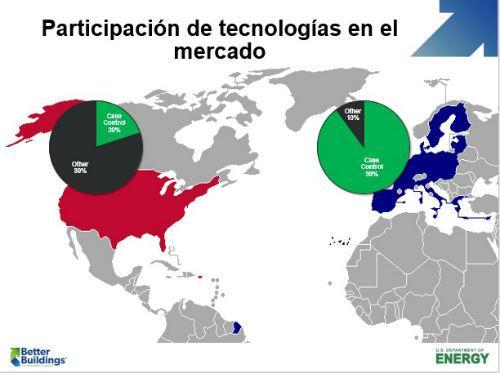

Perhaps the factor that has most impacted the migration from one architecture to another has been the cost of energy, Figure 4 shows how distributed systems, which began in Europe many years ago and in the United States only from the 90's, coincides with the fact that the Old Continent has more than 90% in distributed systems vs. the 20% that the US currently has (Figure 4).

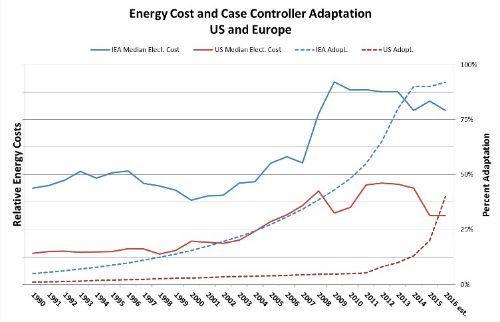

The best and clearest evidence of the way these two variables are associated can be seen in Figure 5, where the higher the energy cost, the higher the % of stores with distributed systems, in Europe, contrary to what has been happening in the United States.

Figure 3. Variables that impact migration to distributed systems.

Figure 4. Participation of technologies in the world market.

Figure 5. Comparison between US and Europe and their growth in distributed systems vs the cost of energy.

Although some of these statements are relative and depend on the market and in the country in which it is analyzed based on the costs of energy, labor and other indirect costs, it could be generalized by saying that the benefits of distributed architectures or control from the furniture are summarized in the following:

- Low installation cost, impacted by retail: pipe laying, less welding and insulation, fewer electrical panels in the field, less sensor wiring, and less refrigerant gas load.

- Lower energy consumption, due to finer adjustment in electronic expansion valves and in turn benefits in low condensation applications.

- Lower maintenance cost because it does not require adjustment of the thermostatic expansion valve, and shorter start-up time. Additionally, it allows light control.

- Higher food quality/safety, by finer temperature control.

- Environmental benefits from lower refrigerant load and lower carbon footprint.

This concept of shortening pipe travel and avoiding efficiency penalties due to pressure drop in the pipes also generated more compact and lighter cooling plants which are very close to refrigerated furniture, either on the roofs or at the head of the refrigerated shelves. Its appearance is similar to an Air Conditioning condensing unit, as shown in Figure 6. This is possible thanks to technologies such as the Scroll compressor that being very light with respect to its capacity allows these models of the well-called MiniRack's or Scroll Pack.

Figure 6. Cooling center for distributed architectures.

Under this concept, the pipe lines are reduced, as shown in Figure 7, under the idea that the units are located near the furniture. All this should be analyzed in the balance of cost overruns, on reinforcing the covers vs. the benefit of not occupying sales area in the engine room

Figure 7. Difference in pipeline paths between a centralized system and a distributed one.

References

- Energy & Store Development Conference (FMI) Minneapolis Sept 2010

DOE ( US Department of Energy )

- http://betterbuildingssolutioncenter.energy.gov/alliance/technology-solution/refrigeration

* Giovanni Barletta is the Technical Manager of Emerson's Andean, Caribbean and Central Americas Area, and current president of the Colombian Association of Air Conditioning and Refrigeration (ACAIRE). You can be contacted at the electronic broker: [email protected]