Empresa Públicas de Medellín (Colombia) already has in operation the Thermal District project, the first of its kind to be built in Latin America, with which it begins to offer a new service: air conditioning on demand.

Empresa Públicas de Medellín (Colombia) already has in operation the Thermal District project, the first of its kind to be built in Latin America, with which it begins to offer a new service: air conditioning on demand.

by José Luis Restrepo Castrillón*

One of the main objectives pursued by EPM is to optimize the energy basket of its customers from the provision of Natural Gas as an efficient, economic and environmentally sustainable fuel. From this objective, the concept of the rational and efficient use of energy [URE] becomes relevant, understanding it as the optimal use of energy in all the links of the different energy chains.

The URE practice must be carried out starting from the selection of an energy source, such as natural gas, optimizing its consumption and including the use of combustion products.

In accordance with the current strategy of the EPM Gas Management, the new project of the La Alpujarra Thermal District in Medellín, will promote the issue of development of new products and services that would imply:

- Knowledge and understanding of customers' businesses.

- Beyond providing natural gas as our basic product, we will offer energy solutions that leverage the survival and growth of the client's company.

- Establish long-term relationships at all levels with our clients and

- Ensure that productive growth is always framed within an environmentally sustainable development

What is a Thermal District?

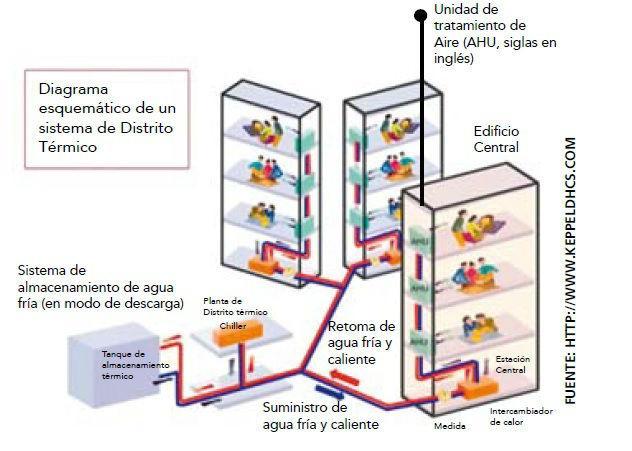

The Thermal District System (SDT) is an urban distribution system that produces steam, hot water and ice water from a central plant and then carries them by pipes to district buildings to heat spaces (heating), to supply domestic hot water and/or for space conditioning (air conditioning). Thus, individual buildings do not need their own boilers or furnaces, or cooling equipment (Chillers), "The Thermal District does that work for them."

The best thing about SDT is that it fits the needs of all consumers in one place and that results can be achieved that an individual system usually could not. For example, in certain cases an SDT may use a variety of conventional (e.g. natural gas) and unconventional (e.g. solar energy) fuels; In addition to the size of an SDT, your plant can be changed to use renewable fuels such as biogas or biomass, among others and not being enough, you can also use the combination of heat and power as an alternative to increase its efficiency.

Buildings connected to the SDT have lower capital costs in the purchase of their equipment because they do not need boilers or coolers, and in addition, they save space that can be used in other needs.

Figure 1.

The owners and managers of the buildings that participate in the SDT can focus on their raison d'être and not have to have expert personnel in the field because it is the professionals of the District who are operating it continuously and have backup systems available. Many of the SDTs operate with a reliability of "9 zeros: 99.999%", according to statistics from IDEA (International District Energy Association)

What is CHP Heat & Power Combination?

The energy problem is not so much the scarcity of energy, but the technical capacity of converting it into useful forms. The desired energies or those that we think of as easy to use, are scarce or it is very expensive to produce them, as is the case of electrical energy. This, moreover, does not exist in nature in a directly usable way; hence the constant need to look for efficient ways to carry out the conversion of natural energy resources -primary energies- into forms of energy useful for the processes of modern society, seeking the greatest efficiency in the transformation. The concept of cogeneration and trigeneration (cogeneration with extension) precisely seeks to achieve greater efficiency and optimization in the conversion of the primary energy resource to useful forms of energy.

Cogeneration, also known as CHP: combined heat and power, is the combined production of thermal energy and electrical or mechanical energy. This process is carried out from the use of a single primary energy source that drives an engine or a turbine according to the type of fuel of natural origin available. Thermal energy is produced in the form of heat that is usually used in the form of hot water or steam. The scope of application of cogeneration is very broad, including industrial sectors, commercial and service facilities, and even residential. Depending on the design and equipment, a cogeneration plant can achieve efficiencies of up to 60%, which is almost double the efficiency of traditional power generation plants.

Trigeneration, also known as CHPC: combined heating, cooling and power generation, is essentially the same cogeneration with the addition of a cold generation process. It is defined as the process of producing four products from the primary source:

1. Electrical or mechanical power generation

2. Steam generation

3. Hot water generation

4. Generation of cold (refrigeration, air conditioning).

The possibilities of the aforementioned processes allow to achieve great operational flexibility according to the demands of each of the products; this implies the possibility of serving many types of applications both in countries with or without climatic seasons.

The efficiency of a trigeneration process depending on the design and equipment can reach efficiencies of up to 90%.

The cold creation process is achieved by recovering heat from the basic cogeneration process (CHP) and using it in a cooling process, also known as ARP: absortion/ adsortion refrigeration plant.

Heat cooling processes are connected to the CHP process in two basic ways:

1. Direct connection: Use of exhaust gases and/or heat obtained from the cooling circuit of the CHP process engine. ·

2. Indirect connection: Use of low pressure steam or hot water from CHP process. Depending on the application and need for cold generation, different types of heat exchanger liquids are used in the process, to achieve the application temperature ranges. Lithium bromide is used for temperature ranges greater than 5 degrees Celsius or ammonia for temperature ranges between –60 and +5 degrees Celsius. Other types of liquids are available that are restricted for environmental reasons.

The sizes of the projects are diverse, even in some developed countries they have managed to implement applications of relatively large size compared to thermoelectric generating plants of traditional size.

La Alpujarra Thermal District, Medellin

The project of the Thermal District (SDT) La Alpujarra of the city of Medellín is a cooling system located in the sector of La Alpujarra, which centrally produces the cold and distributes it through water through underground pipes. The cold will be used in the conditioning of spaces in the buildings and facilities belonging to and adjacent to the sector of the Administrative Center La Alpujarra, among others: 1. Building of the Mayor's Office of Medellín, 2. Municipal Council Building, 3. Building of the Government of Antioquia, 4. Building of the Departmental Assembly, 5. Building of the Metropolitan Area, 6. Building of the Directorate of Taxes and National Customs DIAN and 7. UNE Building (called UNE Tribunales)

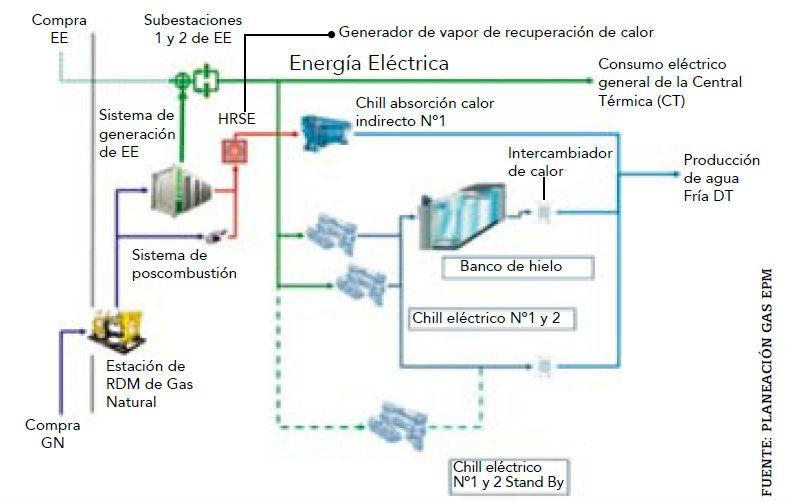

Figure 2.

Technological Configuration of the Thermal Power Plant – CT

The Central plant where the cold production takes place is called the Thermal Power Plant (CT). The main energy or from which TC will work is natural gas. The combustion of this puts into operation a turbogenerator equipment which will generate:

1. Electrical energy to guarantee the operation of the CT in general, including the auxiliary equipment of the chillers (pumps, cooling towers, monitoring and control systems), will also meet the demand for an ice-producing electrical equipment (chiller) which will support the average and peak demand of the buildings of the District.

2. It also produces hot air as a result of the combustion of natural gas, which will serve to operate a chiller of the type of indirect heat absorption that will be responsible for meeting the base load. Chillers of the absorption type are chillers with very different operating characteristics than electric chillers, for example:

- They are silent, produce neither noise nor vibration

- They are environmentally friendly, do not use refrigerants that affect the ozone layer and

- They work from natural gas or indirect heat (hot air, hot water, steam).

Figure 3.

The ice water produced in the central plant or "Thermal Power Plant - CT", is distributed via underground pipes to each of the buildings of the "District" sector, to be used in their air conditioning systems precisely for the air conditioning of spaces, so, each of the buildings that make up the District will obtain the following benefits:

- Saving the space dedicated to electromechanical refrigeration generation equipment; the reduction of the space used for the installation can reach 90% in each building.

- Reduction in investment in electromechanical equipment, maintenance and renovation.

- Outsourcing of management. In general, a unified management allows to optimize the processes.

- Reduction of maintenance personnel.

- Reduction of administrative management in general.

- Reduction of the level of vibrations and noises.

- The network can adapt more quickly to new regulations or efficient technology.

- Reduction in U.S. substation occupancy

Benefits for the entire DT coverage area:

- Improvement of the "city brand".

- Increase in the quality and value of urban space.

- Efficient equipment that reduces the environmental impact and the consumption of the energy resource.

- Centralized management and maintenance that reduce health risk and emission control and, in general, more efficient environmental impact control.

- Possibility of combining thermal generation with electricity (cogeneration, trigeneration) to promote the development of energy efficiency projects.

- Improvement of the urban landscape, by eliminating condensers in facades, cooling towers, etc.

- Reduction of the urban thermal island effect. An urban thermal island is understood as the increase in temperature within urban spaces associated with several factors, such as lack of green spaces, modification of air currents due to the shape of buildings, radiant heat from asphalt and vehicle emissions and, in particular, from the heat dissipated by the equipment that makes up the air conditioning systems of each of the buildings.

- More efficient treatment of noise and safety in generating plants.

- Reduction of overall expenses (energy, maintenance and investment).

- It gives the possibility of using several energy sources improving the autonomy and guaranteeing the continuity and reliability of the service.

- Increase in the reliability and quality of the thermal energy supplied.

* José Luis Restrepo Castrillón is a Technology and Optimization Projects Professional from the EPM Technology and Optimization Projects Unit. You can write to the email: [email protected]