What is the Variable Refrigerant Flow (VRF) system? Why prefer it? This article will clarify many doubts about it.

What is the Variable Refrigerant Flow (VRF) system? Why prefer it? This article will clarify many doubts about it.

by Lennox

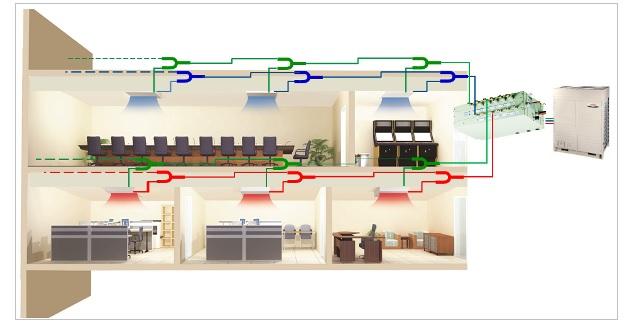

A VRF system consists of an outdoor unit (up to three units combined into a higher capacity module) connected to various types of indoor units through a single refrigerant pipe network.

Each indoor unit, or zone, is controlled by its user or by a central controller that can operate multiple zones. The system constantly varies the amount of refrigerant that passes into each indoor unit to fit the internal load requirement, allowing the compressors to operate only at the capacity needed to meet that load.

This consumes less energy than with on/off systems; even though the runtime of the VRF system is longer. When designed correctly, a VRF system generally operates at a capacity of less than 100%.

Definition

A VRF system is a sophisticated heat pump system. At the most basic level, a VRF (heat pump or heat recovery) system is a heat pump. It features a single outdoor unit connected to various types of indoor units through a single network of refrigerant pipes. In North America all VRF systems currently use R410a refrigerant. ASHRAE and AHRI (Institute of Air Conditioning, Heating and Refrigeration), have formulated a definition of VRF. The main criteria are that the system has a common cooling network and three control steps.

ASHRAE defines VRF as follows: "It is a multi-split direct expansion (DX) system that incorporates at least one variable capacity compressor, which distributes refrigerant through a network of pipes to several indoor air conditioning units, each of which is able to control the temperature of independent zones, through comprehensive zone temperature control devices and a common communications network. The variable refrigerant flow employs three or more control steps in the shared, interconnected pipe."

The AHRI defines VRF as follows: "MULTI-split VRF System: A heat pump or multi-split air conditioner incorporates a single refrigerant circuit, with one or more outdoor units, at least one variable speed compressor or a combination of reciprocating compressors to vary the capacity of the system by three or more steps, several indoor air conditioning units (each of which is measured separately), and are individually controlled by a comprehensive control device and a common communication network. The system is capable of functioning either as an air conditioner or as a heat pump.

VRF Multi-split Heat Recovery System: "It incorporates a single refrigerant circuit, with one or more outdoor units, at least one variable speed compressor, or a combination of reciprocating compressors to vary the capacity of the system in three or more steps, several Fan coil units, each of which is measured separately and are individually controlled by a comprehensive control device and a common communication network. The system is capable of functioning either as an air conditioner or as a heat pump. The system is also able to provide heating and cooling simultaneously, thanks to which energy recovered from indoor units operating in one mode can be transferred to one or more indoor units operating in the other mode.

Evolution

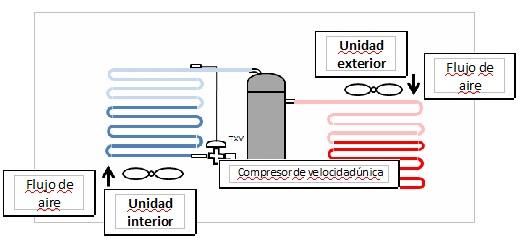

VRF systems function as heat pumps and follow the same cooling cycle as any other cooling equipment. The evolution of VRF systems can be traced back to single-speed air conditioning units. These units had a single-speed compressor, a condenser, a measuring device, and an evaporator. The system could only cool, not heat.

Figure 1

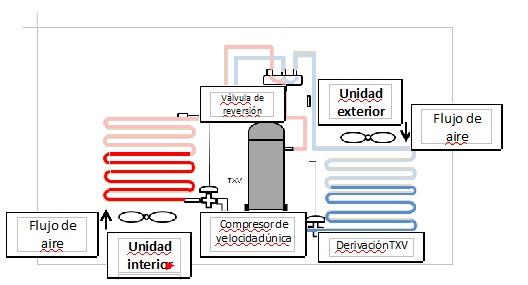

Single-speed air conditioning was followed by the heat pump system; a reversing valve and measuring device were added to both indoor and outdoor units, which were the main components that allowed the system to have the ability to produce heating and cooling without the need for a complementary heating component.

Figure 2

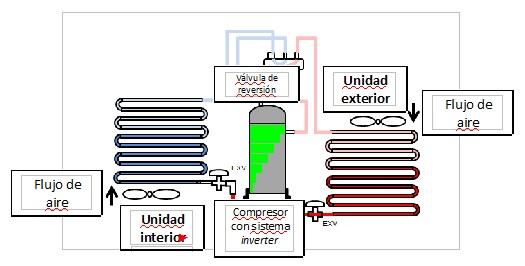

Then, the compressor was introduced with the inverter system to vary the speed and the electric expansion valves that allowed the modulation of the capacity. This provided more precise control and greater capacity.

Figure 3

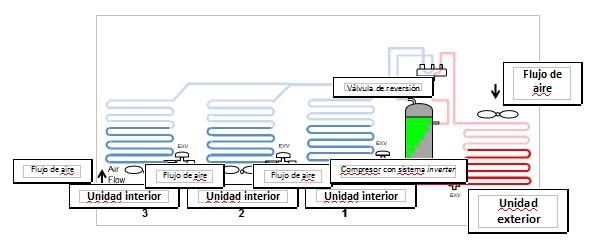

In order to have zoning functions, additional indoor units were added to the system. This made it possible to individually control the temperature of each zone. Thanks to a compressor with inverter system, the system operates at a capacity that adjusts to the internal load, increasing overall efficiency.

Efficiency is achieved by reducing capacity to part-load conditions; most systems operate 60% to 80% of the time at part load. As the additional zones require cooling, the compressor is accelerated to provide the necessary capacity. When the needs of an area are met or the cooling load decreases, the compressor slows down and reduces capacity to the level that is needed only. This makes the system highly efficient as it is only providing the necessary capacity and there is no waste of energy.

Figure 4

Key components

There are two fundamental components in a VRF system: a variable speed compressor, controlled by an inverter system, digitally switched and the electronic expansion valve, or EXV.

VRF systems use inverter technology with electronic expansion valves to control the flow of coolant to vary capacity. The inverter is an electronic component that varies the speed of the compressor. By varying the speed, the mass flow rate of the refrigerant increases or decreases to match the required internal load. This allows the VRF system to produce only the necessary capacity required at any given time. Most VRF manufacturers are using compressors controlled by an inverter system in the outdoor unit.

The electronic expansion valve, EXV, opens and closes in increments that allow the precise amount of refrigerant to flow through the evaporator coil. The EXV also opens to a predetermined position during operation in heating mode to allow the flow of coolant through the condenser, thus making it unnecessary to have a shunt-type check valve. Each indoor unit has an EXV. The EXV has a variable pulse rate that modulates the flow of coolant in the indoor unit. It allows the passage to the indoor unit of the required amount of refrigerant to meet the demand of the area.

Types of systems

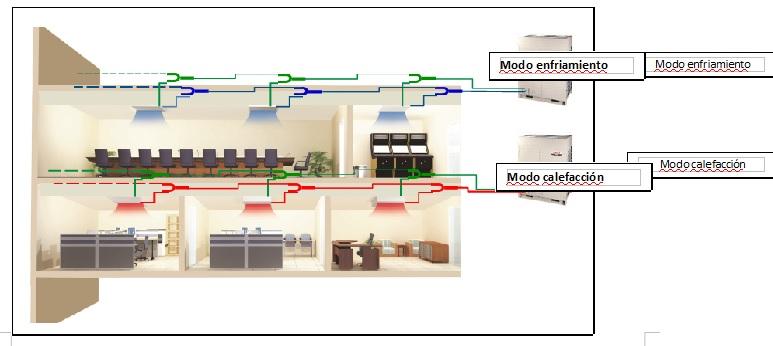

VRFs come in heat pump system and heat recovery system mode. A VRF heat pump system can heat or cool space, it can't do both at the same time. A VRF heat recovery system allows simultaneous heating and cooling of individual spaces. The VRF heat recovery system displaces the recovered heat from one area to another. This is a controlled system of total comfort that allows cooling in one area and heating in another at the same time. The ability to use the waste heat created when a space is cooled to heat a different space represents the true value of the heat recovery system. Most recovery systems contain three tubes: liquid tube, high-pressure gas discharge tube, and low-pressure gas suction tube.

Two heat pump systems

A heat recovery system

Indoor units

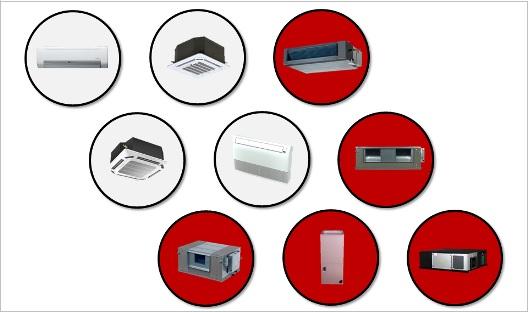

Indoor units come in a wide variety of styles and capacities that fit different applications. Indoor VRF drive styles include ductless units for wall or ceiling mounting. Styles with ducts are usually horizontal and vertical air conditioners of medium and high static.

Figure 5

Mode selection box

In VRF heat recovery systems, a mode selection box, also known as a heat recovery box, is used to allow simultaneous heating and cooling. This box is used to configure the mode of the indoor units located below the selection box.

Figure 6

Controls

VRF controls provide feedback to the VRF system on space load requirements. Normally it is a serial connection communications system that allows the control of the mode of a separate zone (heating or cooling) and the control of the temperature. Using gateways or interfaces, the VRF control system can be connected to BACnet or LonWorks building management systems.

Figure 7

Accessories

Accessories can range from condensate lift pumps to control for auxiliary heating options, refrigerant pipe bypass connections and remote sensors for rooms.

Advantages

VRF systems have many advantages over conventional on/off systems.

Note: To read the second part click here.

Excelente información. Soy el responsable de Higiene y Seguridad en el Trabajo de un Frigorífico en Mar del Plata, Argentina y estoy tratando de disminuir el nivel de ruido de las torres instaladas ya hace muchos años.

¡Éxitos con el proyecto!