In this article we focus on recommendations for the correct use of valves, as well as highlighting the most common mistakes that are made in their implementation within projects.

In this article we focus on recommendations for the correct use of valves, as well as highlighting the most common mistakes that are made in their implementation within projects.

by ACR Latin America

Valves play an indispensable role in the flow control of HVAC/R systems. They are responsible for ensuring the proper functioning of the systems and that the pressures are correct so that the performance of the equipment is not affected.

In the market there are manufacturers that have managed to develop different types of valves and in this article we will know a little about some of them, who, through their representatives, will expose how this sector has evolved and what have been the main recent developments of this type of solutions so important for our market.

For example, Andrea Zardo, Export Area Manager of Caleffi, commented on the technological evolution of these solutions that "at the moment the most current global problems are energy saving and environmental care, strictly connected to the control of consumption in heating and cooling systems. To achieve good results, the precision and reliability of the valves that control the flows in these systems and the integration of their controls are fundamental."

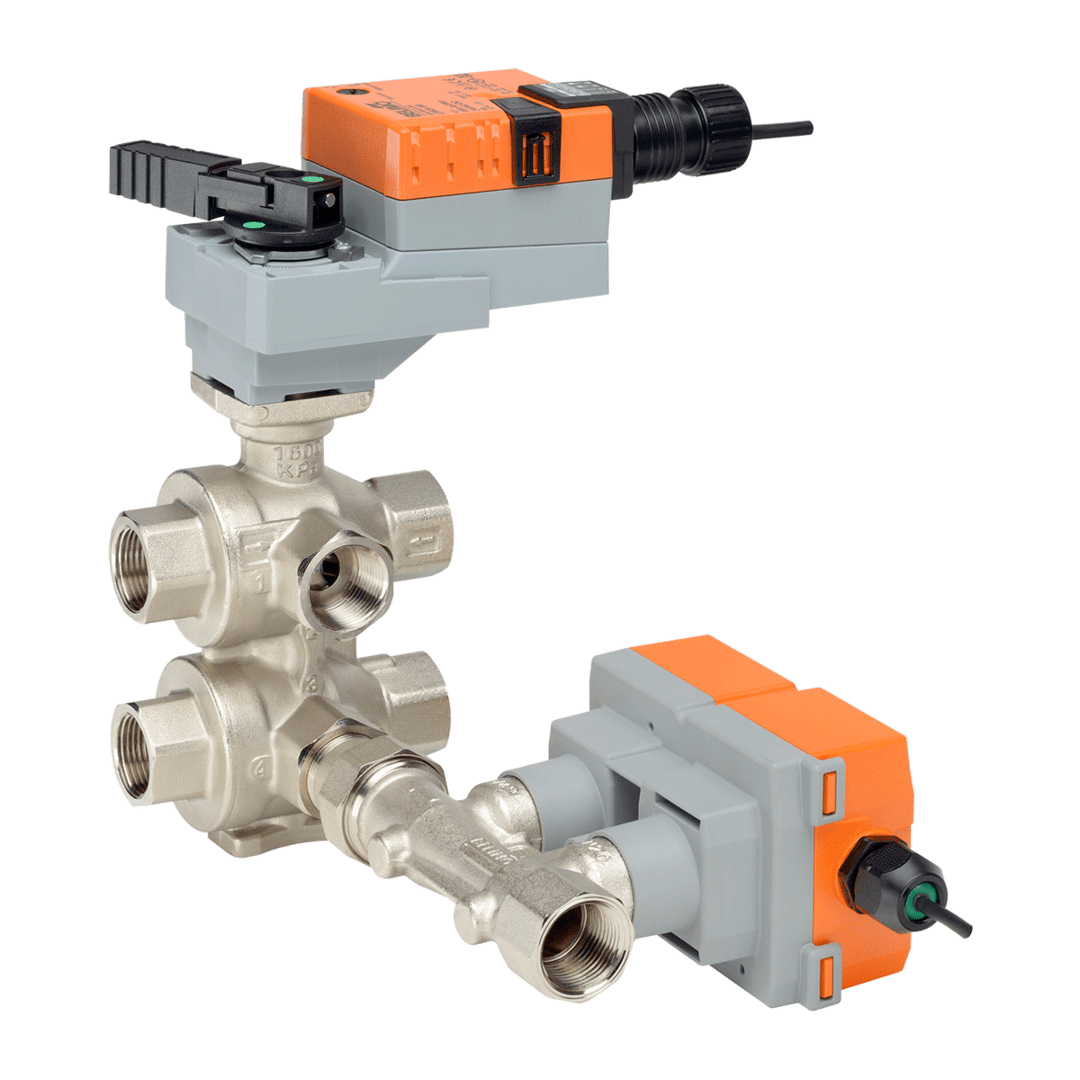

Elsa Yánez, Manager – Latin America of BELIMO Americas, said that "the evolution of these solutions, as in life, has been given from the resolution of existing problems. In the specific case of the Energy Valve (brand solution), the product was the result of a tender for the Massachusetts Institute of Technology (MIT) where it was required to improve the conditions of energy exchange in a building. The result was an intelligent pressure-independent valve, with a real-time flow meter, with the ability to maintain a minimum temperature differential, as well as storage for up to 13 months where energy information can be analyzed in real time, as well as stored information and changes can be made in the energy strategy of a building."

For his part, Alberto Calderano, Commercial Director Spain, Portugal and Latin America of Fratelli Petinaroli, stressed that "today we no longer manufacture only dynamic balancing valves but we were the first to take pre-assembled solutions from the factory that we call hydronic kits, for terminal units customized with respect to the needs of the installer. Many competitors have followed us and this actually makes us very proud. Right now we have more than 2,000 different kits developed in all these years."

Meanwhile, Murylo Santos, Key Account Manager of Carel, presented a list of some aspects that have evolved technologically in the field of valves:

• Step-by-step modulation that ensures more precise control (an average of 0.03mm per step).

• Always stable overheating in the overheating Setpoint that ensures that the temperature of the refrigerated air is stable and consequently also of the food, giving more life time to the cooled products.

• Control with constant variation that ensures that at partial loads of the system the control is precise, and quick response when it is necessary to load the total system. Rapid reaction to system capacity variations.

• Shorter Pull Down time (cooling).

• Bidirectional flow.

• Electronic and mechanical integration.

• Reduction of the compression ratio increasing the efficiency of the system. The required working time of the compressor is shorter.

• Ultracap module that closes all valves 100% in case of blackout and replaces the liquid solenoid valve (no more need for liquid solenoid valve).

• Online software for valve selection

• Manual opening via magnets.

Capabilities of a technician and knowledge of the need

A technician in charge of the installation of a project must know different aspects to get the best performance to the valves. Our guests offer some recommendations in this regard.

Elsa Yánez revealed different concepts that must be included and stressed that control valves are only part of a more complete system. If any other part of the project changes, this will affect the effectiveness in controlling them:

"It is important to take into account certain factors when selecting a valve, such as the type of Fluid (Liquid, steam or gas) to be controlled, the pressure and temperature of the fluid, the service that the valve will provide (cutting, mixing, steering, 2 ways, 3 ways, 6 ways), the frequency and speed of operation, as well as whether it requires protection against the environment. It is also important to install the valves that have been selected by the designer, following the manufacturer's recommendations, in terms of assembly, handling care, appropriate weather protection, according to the place (humid, corrosive environment, with risk of explosion) and perform the best practices in terms of commissioning.

Meanwhile, Andrea Zardo explained in this regard that "the technician must keep in mind the correct dimensioning of each component of the system, according to the required flows and the pressure drops imposed by each element present in the system, this is essential for the correct functioning of the same. An equally important aspect is the collaboration between the designer and the installer of the system, as a perfect balance on paper is useless if not implemented in the right way."

For his part, Moisés Quintanilla Sosa, Offering Manager Leader LATAM BMS of Honeywell explained that it is necessary to "know the maximum flow of the air conditioning equipment and match it to that of the valve, either by calculating the flow coefficient of the coil of the equipment and matching it to that of the valve or selecting a valve that delivers exactly the maximum design flow of the air conditioning equipment. You should also consider the actuator control signal; for air handlers the modulating/proportional control is used more since it is more precise and for fan&coils the floating/on-off control is used more but also to have an ideal temperature control, the modulating/proportional control is the best of all".

Meanwhile, Alberto Calderano also touches on an important point such as the real flows: "We consider a correct selection of valves a priority with respect to the real flows that are needed in the project to improve the performance of these products. Regarding this aspect, we always prefer to help the engineers and installers in a complete analysis of the most accurate valves".

Most common installation errors

According to the experience of the guest manufacturers, below we present some of the most common mistakes made in projects involving the installation of valves in HVAC / R.

Murylo Santos, from Carel, points out two errors: "Reversal of connection position of valve cables and sensors; and needle damage at valve closure."

Andrea Zardo, of Caleffi, commented that although the installers continue with greater boom the recommendations of the manufacturers "there are still errors of assembly of the valves, changes in the pipes of return and return, or connections too tight that lead to losses of tightness. At the moment there is a very important installation aspect: the cleaning of the installation. This was always a very important issue but today it is even more so, because smaller flows are increasingly used (as a result of improvements in building codes and efficiency of the facilities) and balancing valves work with an increasingly narrow step. Therefore, cleaning the installation before commissioning is essential and they still do not devote enough time to this."

Elsa Yánez of Belimo Americas shared her concepts as follows: "The most common handling errors happen when taking valves as a part of the piping system. Although they are installed in them, it is important to treat them as part of the control system. They have electronic components that are fragile and must be handled with care."

Other failures were highlighted by Moisés Quintanilla, of Honeywell: "Install the valve in the opposite direction to the flow, do not place Teflon or sealant in the joints, make an incorrect electrical connection, do not confine the signal of the actuator with the control signal of the thermostat / controller".

The market in Latin America

Our guests agreed not to mention in a great way the possible effects on the industry due to Covid. On the contrary, the experience of many was positive despite this phenomenon. In ACR Latin America we analyze, as a reference, the specific behavior of pressure reducing valves (see graphs) in some of the most important countries in our region, in addition to the largest importers of this class of valves.

Already analyzing the experience of companies on the valve market in LATAM, the representative of Honeywell, for example, commented that in our region there is still a way to go in terms of the implementation of the latest technologies: "The market is quite competitive, but new technologies are not yet implemented in the Latin American market. For example, Honeywell developed its first series of PICV control and balancing valves, VRN2 Series since 2009 and they are barely being considered in water HVAC specifications and projects."

In the case of Carel, the company had no impact on either sales or valve deliveries due to Covid. "We are seeing an increase in demand for our valve technology," said Myrulo Santos.

Andrea Zardo, for his part, believes that the latest is being implemented in our region: "In Latin America there are the most contemporary solutions at a global level. Pressure-independent flow regulation solutions are the norm in all spectrums. From the project to the installation and commissioning. Unbalanced circuits have operating characteristics that can cause problems in the distribution of liquid to terminals. To work around this problem, two types of balancing devices are generally used:

- Static devices: they are manual instruments of traditional type suitable in general for circuits of constant flow or with few variations of load.

- Dynamic devices: they are modern automatic devices, suitable mainly for variable flow installations, with very frequent change of thermal loads".

Alberto Calderano, from Petinarolli, said on this subject that "in reality the markets of Latin America are very different from each other; some are more advanced and others less but there is a very large culture in air conditioning that has developed in all these years. We began to push these markets very recently, but we must recognize that Latino engineers and installers are greatly appreciating our solutions since they are focused on a vision of energy saving that today is one of the priority issues worldwide. "

Future developments for valves

New information technologies will also influence the operation and positive results of the valves. In fact, electronics are already making a difference and developers will continue to bet on there.

Our guests agree on this by mentioning the type of valve solutions that we can expect within the next few years for the HVAC/R market. Here are some of the manufacturers' forecasts:

• Smarter, cloud-connected valves with real-time analytics - Moisés Quintanilla, Honeywell.

• We consider that the same phenomenon that happened in the 90s with the popularization of electronic fuel injection in automobiles, massively replacing carburetor technology, will occur now in this decade with the replacement of mechanical thermostatic expansion valves by electronic expansion valves – Murylo Santos, Carel.

• There are many projects actually open and the world is running a lot despite the current pandemic situation we are experiencing. Every year our sector is always advancing more and we believe that this is a good that favors all of us manufacturers and new ideas - Alberto Calderano - Petinarolli.

• For the hydraulic part the market has reached a certain maturity and, therefore, we do not expect great innovations for the mechanical part of the valves, on the other hand, the integration of the control systems and the mobile access to the applications that allow the user to program the systems according to their needs is the present and will probably be the near future of the sector – Andrea Zardo – Caleffi.

• It is a question, which can only be answered as the innovations come out, since certain information is confidential, so I comment that the evolution of the valves will go hand in hand with the needs of the HVAC systems that are designed for the future. I believe that our company has been a pioneer many times in having products more advanced than traditional systems, and only a few who trust us follow us in our innovations. Later the other adopters follow them. Let's hope, for the sake of our planet, that all valve manufacturing companies will focus on efficient technologies that contribute to the lower energy impact of the systems.

* Find the full article in our Digital Edition.

Leave your comment