Second part of this analysis and recommendations to properly design a hospital, taking into account the current demands as a result of the pandemic.

Second part of this analysis and recommendations to properly design a hospital, taking into account the current demands as a result of the pandemic.

by Alejandro Suárez J. and Julio Rojas S.*

The design and architecture of hospitals were the main topics handled in the first part of this article that you can find in the 23-6 edition of 2020. Now, in this second part we will deal with the issue of air conditioning in hospital facilities, the electrical installation and the conclusions of this study.

Air conditioning

We know that today both ASHRAE and UNE do not recommend that the air conditioning in critical enclosures have systems with positive and negative pressure control indistinctly, the current pandemic situation that the world is experiencing with the COVID19 virus, forces us to rethink such a situation given that to this day there are no surgical pavilions with negative pressures, similarly, ICU-ICUs are not designed with negative pressures.

Taking into account the current contingency, in the case of pandemics or high demands for critical infectious services, the design of air conditioning for critical areas such as: surgical pavilions, ICU-ICU, isolated patients, Emergency Box and other critical enclosures, must have the possibility of managing at will the internal environmental pressures of enclosures to provide indistinctly positive and / or negative pressure with biological barriers granted by hePA H14 terminal filters, both in the injection and in the extraction of air in the air ducts, the air extractions for these enclosures will be between 20-30 centimeters on the finished floor (NPT), with the exception of operating rooms that will have extraction at the level of 30 centimeters of NPT (70% of the extraction flow) and at the level of 220 centimeters high (30% of the extraction flow), the reconversion of pressures will be the absolute responsibility of the medical staff with the appropriate health protocols, there will be a digital panel at the entrance to each enclosure that indicates the programmed pressure according to the selection.

To comply with the provisions of this section, all the UMAS must be selected for the highest flow that results from the most critical condition, for example in the selection of isolated enclosures, the UMA will be selected by the flow resulting from the 20-30 renewals demanded by immunocompromised patients, in the case of ICU / ICU the selection of the UMAS will be the 12 renewals demanded by infectious patients, in the case of Pavilions the selection of Injection and return will be equal to the higher flow, in this case equal to the impulsion flow.

The operating point of the UMAS in normal case or pandemic mode, will be controlled by the centralized control of air conditioning, considering that the UMAS have fans with EC motors, for this case it is also possible to consider that the UMAS can have more than one fan both in the impulsion and in the return.

Finally, the UMAS will contain an empty module to house Hepa H14 filters, which will be used in pandemic mode, this saturated filter pressure drop must be considered in the selection of the UMA and controlled by the EC variable speed drive of the UMA itself. This same situation will apply to isolated enclosures when required in case of infected patients, with the difference that the Hepa H14 filter will be incorporated into the extraction grid of the "Isolated Patient" enclosure room.

It is a system composed of a variable air flow management unit that is responsible not only for the treatment of ventilation outside air but also to provide all the air required to maintain the hygrothermal conditions of the premises.

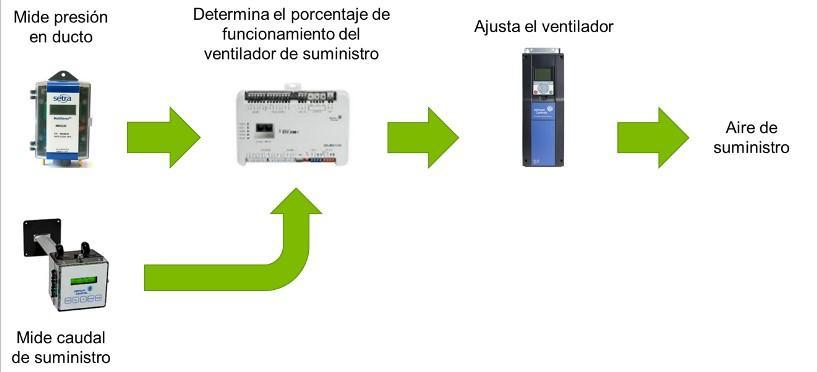

All handlers will ensure the minimum flow necessary for the multiple areas to which it will feed as an air source. Each air handling unit must have a pressure control loop in the duct, governed by a differential pressure transmitter, which will control the speed of the fan through the frequency inverter of the equipment, this control loop will allow to adjust the speed of the fan in case of saturation of the different air filters of the equipment or in the case of the opening / closing of the different venturi valves of each zone.

Figure 1.

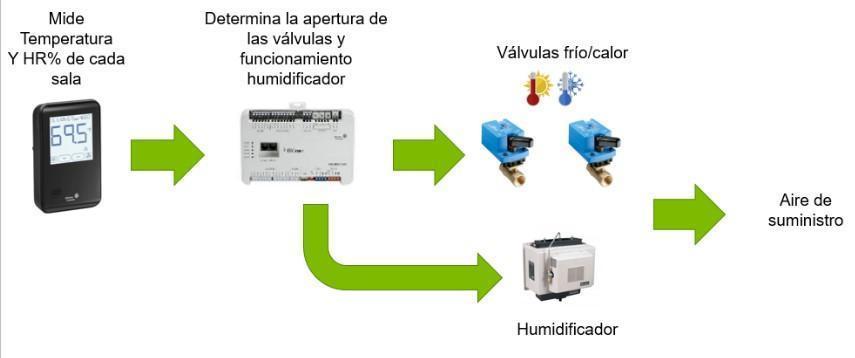

Each air handler must control the temperature and relative humidity of the air in the injection duct of the different sites, The setpoint of temperature and relative humidity of the duct must be self-adjusted in order to meet the requirements of each room.

Figure 2.

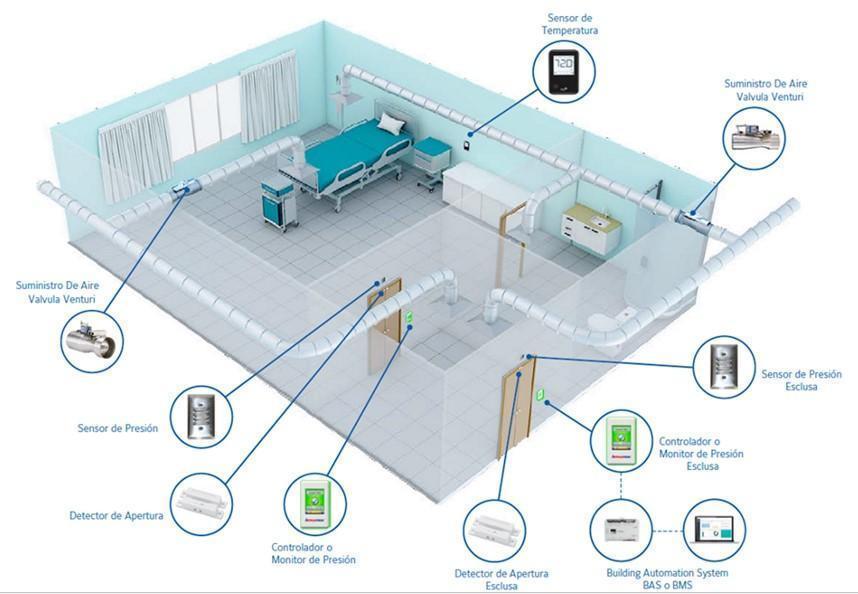

In order to control the temperature and relative humidity of each enclosure independently, the control panel located in each room will control the switching on and off of the refueling module of the supply air coming from the air handling unit.

Figure 3.

In the indicated areas, UMAS of high hygienic requirements will be available, all outdoor air with three or four degrees of filtration to achieve 95% or 99.97% HEPA, as indicated in ASHARE or UNE standards for each enclosure.

The 99.97% HEPA H14 filtration stage will be included within the handler in all cases except in: Pharmacy areas closed attention, clean sterilization area, pathological anatomy laboratory, sections of clinical laboratories, pavilions, SEDILE and isolated patient rooms; in which the H14 filters will be installed in the final air injection diffusers, in isolated enclosures and infectious enclosures, in addition H14 filter will be installed in the extraction as a bacteriological barrier, it will be located within the attached enclosure as close as possible to the extraction grid (s).

As a general rule, the spaces that require special conditions of positive/negative relative pressure with respect to the adjacent ones, are monitored by controllers / monitors of differential pressure in the environment, whose readings will serve to control the fans with EC motors of impulsion and extraction and of the motorized regulation valves of air flow in ducts.

Figure 4.

Figure 5.

Clinical gases

The supply of medical gases is vital so in the new hospital design it will demand greater capacity and a greater number of medical gas intakes.

Considerations:

to. Design mirror plants with the capacity to meet the demands and pandemic mode.

b. Provide gases in enclosures: Triage, Waiting Rooms in Emergencies, Emergency Box, Isolated Enclosures and Hospitalization Enclosures with number of gas intakes similar to ICU / ICU.

c. Provide air intakes in critical corridors of the mural or sky type.

d. Provide matrices with sufficient capacity to provide medical gases to the Modular Hospital and the last level of the building which will be used in Pandemic Mode

Wiring

As explained in the previous sections, the change of service of a hospital from having normal operation, for which it has been designed and built, to converting and performing a pandemic hospital service entails an important rethinking of its facilities; new requirements for air conditioning and pressurization, forecast of corridors and areas that will accommodate beds, emergency areas adapted to areas with stretchers, etc.

For everything to be essential to consider the electrical needs that the new situation will have. As has been proposed, the new needs of feeding receivers and enclosures must be taken into account, which in the normal and / or standard operation of the hospital are not required, such as:

• Triage: completely separated and sectorized from the point of view of controlling the negative pressure of the air, equipped with medical gases.

• Emergencies: completely separated and sectorized from the point of view of controlling the negative pressure of the air, equipped with medical gases.

• Triage and Urgency: Equipped with video cameras and some communication points and plugs in case patients require monitors while waiting for attention shift.

• Emergency Box: designed with the concept of hospitalization, that is, with installations of medical gases, electrical, weak currents, air renewals considered for infected patients of 12 changes per hour and differential pressure control.

• Critical Corridors of the Hospital: they will be provided with the number of power outlets of force and weak currents and video recording cameras necessary to attend to patients located on corridor stretchers. The energy demand due to the air conditioning conditions of these corridors will be considered when in pandemic use, taking into account the conditions of temperature control and differential air pressure.

• Hospitalization surfaces converted to ICU/ICU, equipped with headboards or CPI equal to those of ICU/ICU, with the necessary amounts of strength and control points.

• Electrical Power considered for the extension of surface in the last level.

• Incorporate in the design of BMS, access control by priority levels in case of pandemic and prevent unwanted access, accompanied by CCTV cameras.

The increase in consumption must be considered at the design stage so that the power supplies are able to supply the needs of the hospital when their operation has been adapted to the pandemic.

Programmed growth

The scheduled growth of the Hospital includes the construction of an upper floor, with vertical circulation systems (elevators and stairs) and facilities (electrical, air conditioning, medical gases, etc.). Of course, this increase in demand should be foreseen in terms of supplies and facilities. This increase in power should be considered in the design phase since the increase in beds, taking into account that all of them would be dedicated to the care of infectious patients, is the equivalent of a closed care floor, that is, 204 beds as indicated in this proposal. For them, the Transformation Center must be sized, as well as the reserve feed in the sense of being able to supply the proposed increase.

It is important to consider and have planned the gaps for the passage of the facilities, wiring trays, ventilation conductor, pipes, to the upper floor to enable, since this forecast would speed up the start-up of this new plant.

Hospital Modular

For the electrical supply of the Modular Hospital, it is proposed to install a double independent electrical supply and exclusive use for it, which would come into use when the Modular Hospital is assembled, serving the General Distribution and Command Panel destined exclusively to the facilities of the same.

For the demand for power, it should be considered that the Modular Hospital will have hospitalization areas, emergency rooms, delivery pavilions, ICU / ICU, minor imaging, minor feeding center, Waste areas, changing rooms, bathrooms and showers, etc.

Likewise, it is important to keep in mind the increase in electricity consumption due to the refrigeration necessary for the mortuary.

Conclusions

The conditions that arise today in the world such as climate change and the great mobility of people to be able to be anywhere in the world in just a few hours are situations conducive to expanding pandemics to all corners of the world, almost without restrictions, so it is essential to take the necessary measures to better face a pandemic or health emergency, as is the case in which we are being affected by COVID 19, which to this day could not be controlled.

It has been shown that no country was prepared for an emergency like this, the situation is further aggravated in those countries where public health does not have resources or has been diminished by health privatizations or public health simply does not exist. It has been intended in our proposal to generate a contribution to the ideas that we hope the international community will consider, therefore, we suggest the following based on what is described in this document and the experience observed at this time:

1. Reformulate Primary Health Care, who are the first line of detection containment and traceability.

2. To consider what is stated in this document, within it, is to quickly reconvert the hospital to pandemic mode.

3. Install the modular hospital in advance and quickly.

4. Fully differentiate and zone care in the hospital building in pandemic mode

5. Eliminate the bottlenecks that are generated in the Emergency and ICU / ICU, reconverting the hospital in time to pandemic mode.

6. Convert complete hospitalization areas, critical corridors and emergency box into ICU/ICU.

7. The Hospitalization floor destined to be converted into icu-ICU, must have larger corridors and glazed partitions arranged towards the corridor.

8. Use the normally uninhabited upper floor in a field hospital.

9. Generate modifications to the UNE and ASHRAE standards, where today they establish only positive or negative pressures to the enclosures already described, this situation must accept the reconversion according to the nature of the patient's condition.

10. All hospital designs must be subjected to computational simulation of dynamic fluids (CFDs), people flows, waste streams, possible virus flows, etc. As a way of seeing how the eventual spread of viruses or bacteria could behave.

11. Certify the air quality in the entire hospital building, understanding by air quality: total air renewals, new air renewals, pressure levels, Temperature, relative humidity, level of filtering stages, filtering classification according to ISO standards, environmental particle count, CO2 level, % of CFU, direction of air flow through enclosures.

12. Both vertical and horizontal circulations must be differentiated and sectorized in order to control the flow

13. Generate differentiated areas for the removal of waste, corpses and other contaminated media duly sealed and refrigerated

14. The installations must be considered in the initial project and executed at the construction stage, leaving the start-ups duly protected and arranged.

15. Consider the vulnerabilities necessary to prevent collapse in the face of a simultaneous event of an onslaught of nature and pandemic.

16. Finally, medical, paramedical and auxiliary personnel must be trained in the work carried out in the ICU-ICU since it has been demonstrated in this pandemic that not all personnel have the necessary knowledge to operate the equipment and ventilators of these enclosures.

* Alejandro Suárez J., Architect / Julio Rojas S., – Mechanical Engineer and Technical Manager of R&C Ingeniería. www.ryc-ingenieria.cl

Leave your comment